You may know that Dursan® is a great coating for field sampling and transfer applications (like oil & gas or environmental) . But I bet you didn't know just how corrosion resistant Dursan is.

Here are a few examples demonstrating Dursan® corrosion resistance.

Take a cup of 15% bleach and throw in a Dursan coated coupon and a competitor coated coupon.

The competitor coupon will look something like this;

The Dursan coupon will look like this;

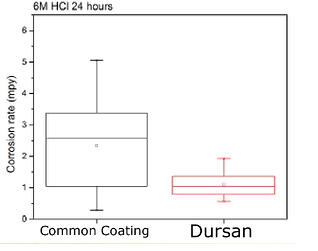

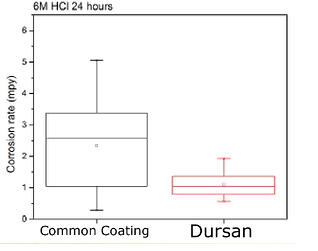

Calculate the coating loss in mils per year and the comparison looks like this;

Quite a difference! By comparison, stainless steel is even worse!

What about hydrochloric acid?

Hydrochloric acid corrosion problems? Dursan can help prevent damage to your process and avoid contamination of your product.

To demonstrate how a process stream may become contaminated, let's take a beaker of concentrated hydrochloric acid (note how clear the acid is before immersing a coupon) then throw in a stainless steel, duplex or a competitor coated coupon. Wait a day and note the color of the beaker, GREEN! The acid, or in our simulation, the process stream is now contaminated by the nickel, iron and other metals leached from the stainless steel.

Then check out the Dursan coated beaker, looks pretty clear to me,

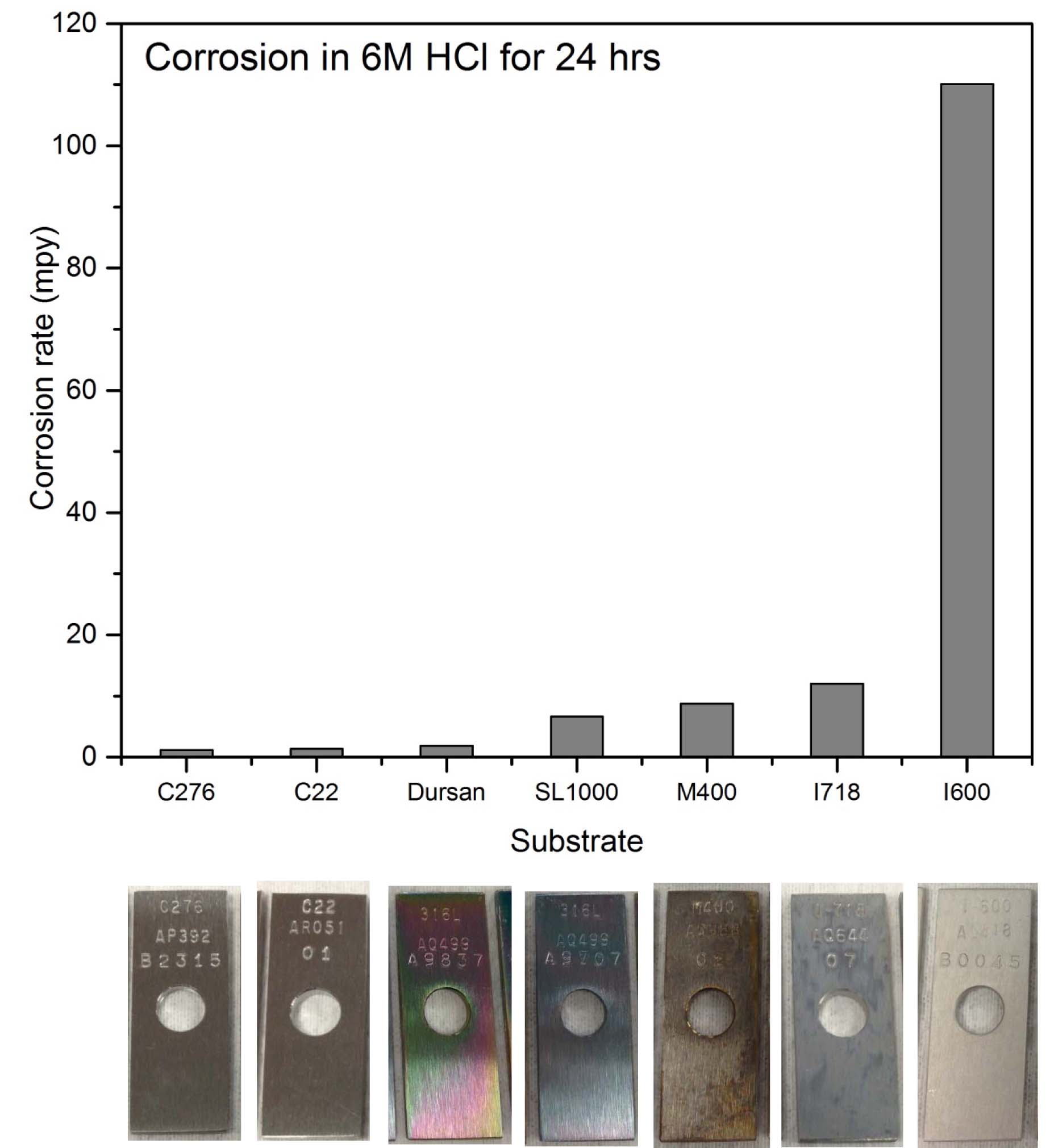

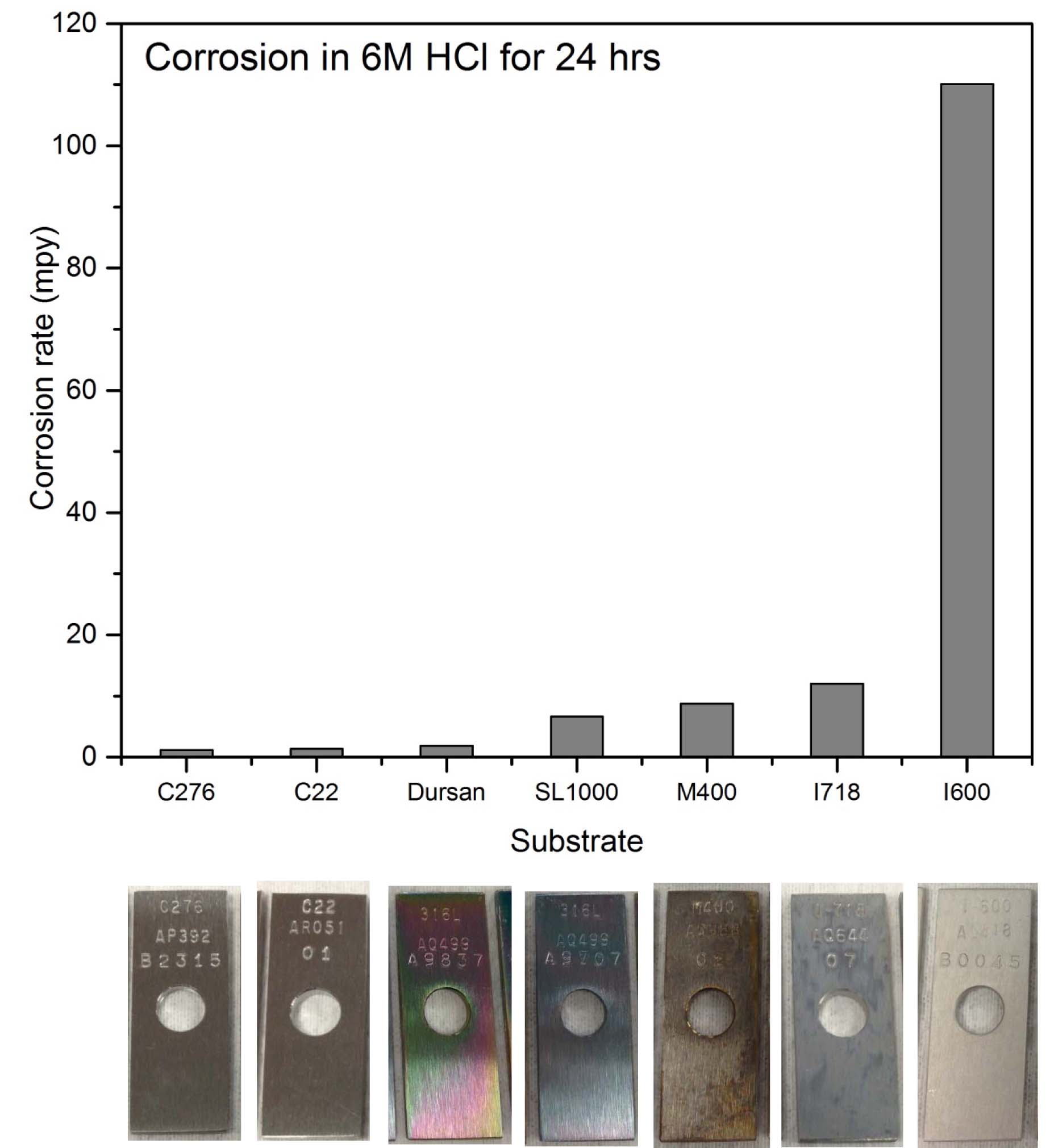

Graph the results in mils per year and results look like this;

Comparing multiple coupon materials, Dursan® demonstrates similar performance to Hastelloy®

.jpg?width=398&name=corrosion_comparison_in_HCl_(4).jpg)

Why is this important?

If you're sampling in a reactive environment, it makes sense to avoid sample contamination and damage to the sample pathway by coating wetted surfaces with an inert, corrosion resistant coating. If you're a semiconductor manufacturer or other high purity processor, Dursan helps to avoid product contamination and extends the life of process equipment.

Coat the entire sample pathway.

Dursan® can be applied to the entire wetted pathway, or wherever corrosion can damage processes or products .

Coat:

| Regulators |

Valves and fittings |

| Tubing |

Sample Cylinders |

| High purity gas delivery systems |

Semiconductor gas manifolds |

| Process sample probes |

Glass and ceramics |

Learn more.

.jpg?width=398&name=corrosion_comparison_in_HCl_(4).jpg)