In an article published by the Qatar Environment and Energy Institute (QEERI), it was explained that the corrosion protective coatings market has experienced significant growth over the past five years, driven by the essential role these coatings play in protecting infrastructure and extending the lifespan of industrial products. Despite global economic challenges like the COVID-19 pandemic and geopolitical conflicts, the market is projected to grow at a 5% Compound Annual Growth Rate (CAGR) from 2023 to 2029. Major infrastructure projects, such as China's Belt and Road Initiative and the U.S. Bipartisan Infrastructure Law, continue to fuel demand, particularly in Asia, which accounts for 55% of global consumption.

Environmental concerns are reshaping the industry, with a shift toward eco-friendly coatings that reduce Volatile Organic Compounds (VOCs). The market's future looks promising, with ongoing technological advancements and increased production efficiency expected to lower costs and support sustainable growth, despite challenges like potential raw material shortages. QEERI specifically named SilcoTek's Silcolloy coating as a lifecycle cost saving product in the corrosion resistant coatings market. Unlike some other coating methods, SilcoTek’s CVD processes deposit a thin (0.0005µm – 2µm) layer bonded to a customer’s substrate. SilcoTek's non-PFAS coatings are made up of the Earth’s elements like silicon, oxygen, carbon, and hydrogen and do not contain any fluorinated chemicals, solvents, or forever chemicals that require special disposal.

Where Does SilcoTek Fit In?

In a world where material selection options are often limited, SilcoTek® offers coating solutions that don't require costly super alloys. SilcoTek corrosion resistant barrier coatings prevent flow path surface interaction with corrosives; extending component life while preventing product contamination. Our corrosion resistant coatings, Silcolloy®, Dursox® and Dursan®, are particularly useful for fighting corrosion in high purity or otherwise sensitive processes in semiconductor, pharmaceutical, research, and complex chemistry applications. In addition to extending the usable life of precision stainless steel parts, SilcoTek coatings even prevent nano-scale corrosive reactions that can cause metal ion leaching and contamination, ultimately increasing process yield and reducing failure rates.

Solve Difficult Corrosion Problems

SilcoTek coatings help to prevent common corrosion related problems including:

- Frequent component replacement

- Process or product contamination problems

- High maintenance costs

- Sample probe damage and failure

- Lost productivity due to excessive downtime

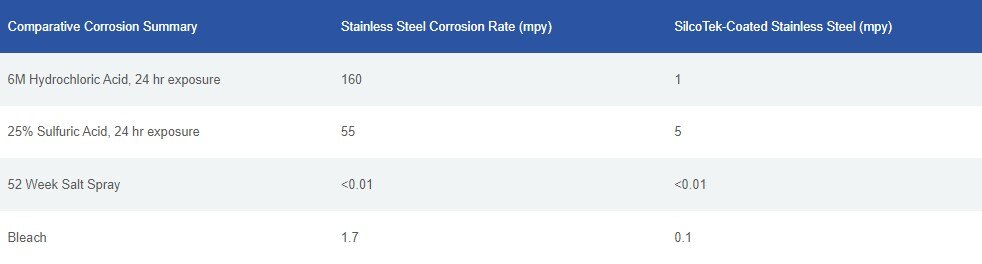

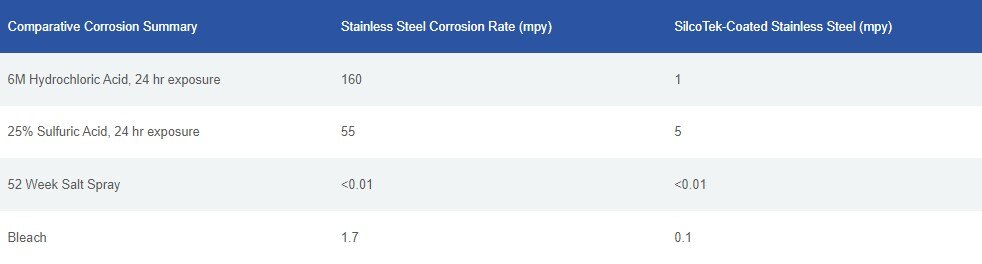

ASTM immersion testing proves SilcoTek coated stainless steel enhances corrosion resistance by orders of magnitude, matching the performance of super alloys in many applications. Even after immersion in concentrated hydrochloric acid (below) the Dursan and Silcolloy coated stainless steel coupons continue to perform with minimal corrosion, demonstrating performance comparable to super alloys.

SilcoTek coatings perform in a variety of corrosive environments including sulfuric acid and bleach.

Siltride shines as a coating for corrosion protection. The graphs below show it outperforming uncoated coupons and various other SilcoTek coatings.

We also performed testing on hydrochloric acid and sulfuric acid to see how Siltride would compare. Check out the results below!

6M (18.5% HCl) 7 days at room temp. - Coupons were immersed in 6M HCl for 7 days at room temp. (ASTM G31). This test shows an aggressive environment testing the limits of Siltride. In these conditions, Siltride performed well with minimal corrosion while considerably

outperforming uncoated 316L SS. Minimal corrosion, outperforms 316L SS by over 35x at 4.7 mpy.

50% H2SO4 1 Week - Coupons were immersed in 50 wt% H2SO4 for 168 hours at room temp. (ASTM G31).When measuring the average corrosion rate (mpy), Siltride showed a nearly 7x improvement over uncoated 316L SS.

50% H2SO4 1 Week - Coupons were immersed in 50 wt% H2SO4 for 168 hours at room temp. (ASTM G31).When measuring the average corrosion rate (mpy), Siltride showed a nearly 7x improvement over uncoated 316L SS.

SilcoTek-coated tubing showing that the tube is coated internally and externally.

SilcoTek-coated tubing showing that the tube is coated internally and externally.

If you have any questions about SilcoTek's corrosion resistant coatings, please reach out to our coating experts!

Follow Us on Social Media!

Reference:

Qatar Environment & Energy Research Institute - QEERI. (2024, January 2). We need to pay closer attention to the anti-corrosion coatings market. The Anti-Corrosion Coatings Market Is Growing Fast. https://www.linkedin.com/pulse/we-need-pay-closer-attention-anti-corrosion-coatings-market-qeeri-lgaqf/?trackingId=9cAsiYzfRoqpvdSLmiEEwg%3D%3D

SilcoTek-coated tubing showing that the tube is coated internally and externally.

SilcoTek-coated tubing showing that the tube is coated internally and externally.