Get Information About the Benefits of Dursan Coated Analytical Flow Paths

Dursan® is a functionalized silica-like coating (a-SiOX:CYHZ) that creates a barrier between your sample and the surface of your equipment. As the price of PEEK increases, we wanted to introduce you to a different, less costly solution to your inertness needs in the HPLC domain.

An inert flow path is necessary in modern HPLC analysis in order to manage the complex and reactive samples commonly used in today’s fast-paced analytical world. Current LC systems feature an array of materials including costly alloys and polymers like PEEK to achieve inertness, but these materials come with their own set of limitations. Dursan is a coating for stainless steel that provides equal or better inertness than PEEK along with the robustness of stainless steel. Dursan is a simple and cost-effective solution for parts requiring inert properties throughout the lab.

Dursan resists corrosive attacks and damage to stainless steel flow paths. The inert surface creates a thin but robust barrier, preventing interaction of corrosives with the underlying surface. Dursan also prevents sample contamination caused by the leaching of metal ions from stainless steel, titanium, and exotic alloy materials of construction in liquid chromatography instrumentation flow paths. This leaching effect occurs due to micro-corrosive effects of certain sample media and even common HPLC solvents like THF, acetone, and more. Despite Dursan’s excellent barrier properties, the coating is no thicker than 1 micron, so you don’t have to worry about the dimensions of your equipment changing or interfering with your analysis. The gas-phase nature of the chemical vapor deposition (CVD) process used to apply Dursan ensures that pores of frits are sufficiently coated but not clogged. Dursan has a naturally thinner profile in frit pores and other high aspect ratio regions.

The benefits of an inert flow path in HPLC include:

- Coat columns and frits for an inert surface like PEEK, but as robust as stainless steel.

- All the inertness and performance of PEEK without swelling, assuring consistent column performance.

- Enhance peak shape, prevent lost peaks, and strengthen test consistency.

- Improved performance with compounds like chelating agents, proteins, and biologics.

- Saving time and money getting the right results the first time, every time.

| Material |

Temperature Stability |

Solvent Performance |

Corrosion Resistance |

Delamination Issues |

Mechanical Strength |

Work-ability |

| Dursan-coated Stainless Steel |

450°C |

No swelling |

Resistant to most known HPLC solvents |

Molecularly bound and will not flake off |

Limited only by the base material |

Precision coating does not significantly alter dimensions |

| PEEK |

148°C |

Swells with THF, Acetone & more |

Incompatible with some acids, halides, chlorides and buffers |

Lined tubing can experience delamination issues |

Begins to flex at 3000 to 5000 PSI |

Inconsistent machining can disrupt flow and shift retention times |

Because Dursan is inert, the coating won't negatively impact the performance of test molecules and will improve the performance of compounds like:

- Chelating agents

- Proteins

- Organic molecules

Let's discuss comparative test results and learn more about the performance of CVD coated flow paths in HPLC applications. For more information about our metal free performance coating technology get our presentation or watch our webinar.

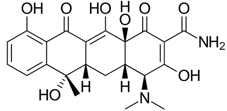

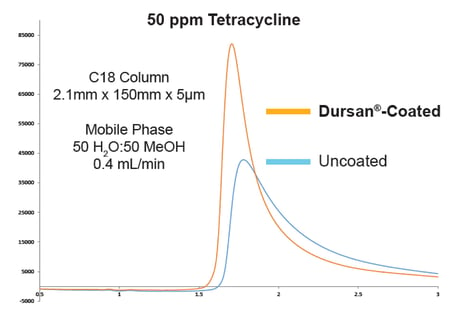

Chelating agents like tetracycline

- Tetracycline is an antibiotic, commonly used for acne and skin infections

- The molecule has numerous chelating groups that bind readily to metal sites

- Dursan can make the steel column more inert toward metal loving molecules like tetracycline

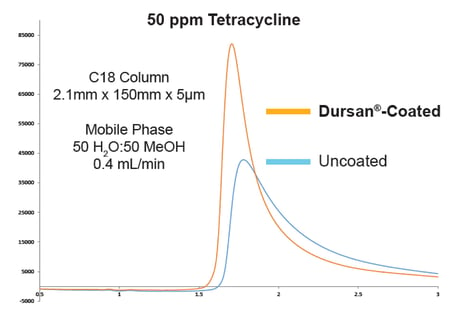

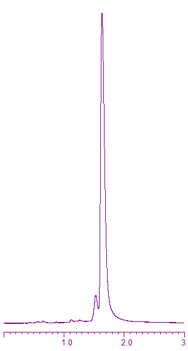

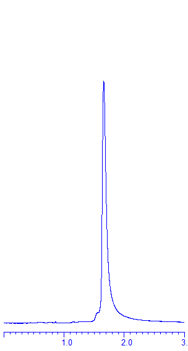

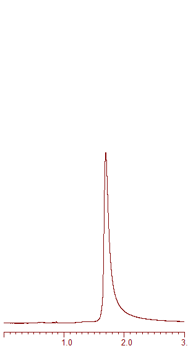

The comparative chromatograph below tells the story. The resolution quality of tetracycline on a stainless steel column showed poor peak shape and response. The Dursan coated column significantly improved the peak shape and significantly improved response.

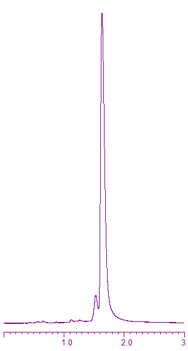

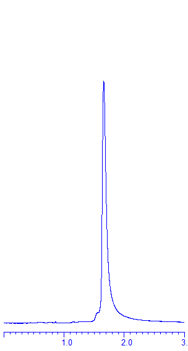

Dursan prevents chelating groups from binding to metal sites. This can be a significant issue for high surface area components like sintered metal frits. Let's compare the peak shape performance of coated and uncoated frits and columns for chelating applications.

Parameters for the test were:

- Mobile Phase A: Water

- Mobile Phase B: Methanol

- 40% B

- Flow: 0.3mL/min

- Detection: 265nm

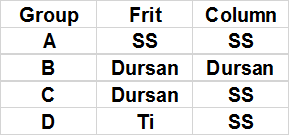

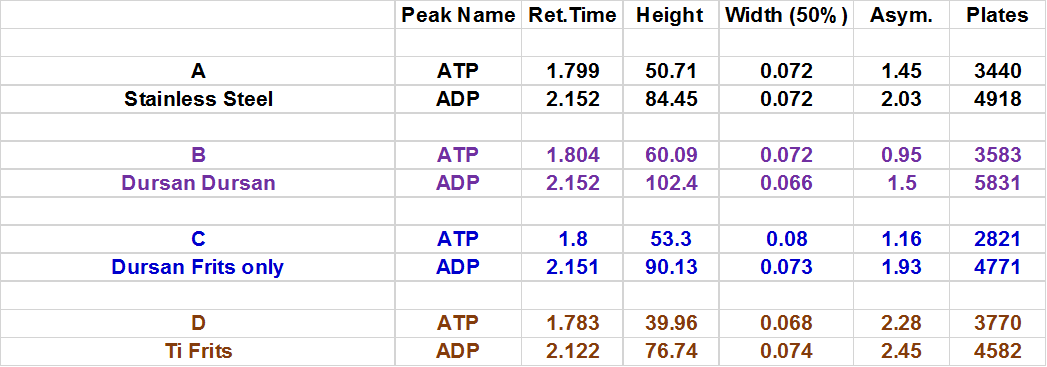

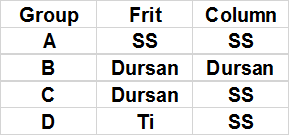

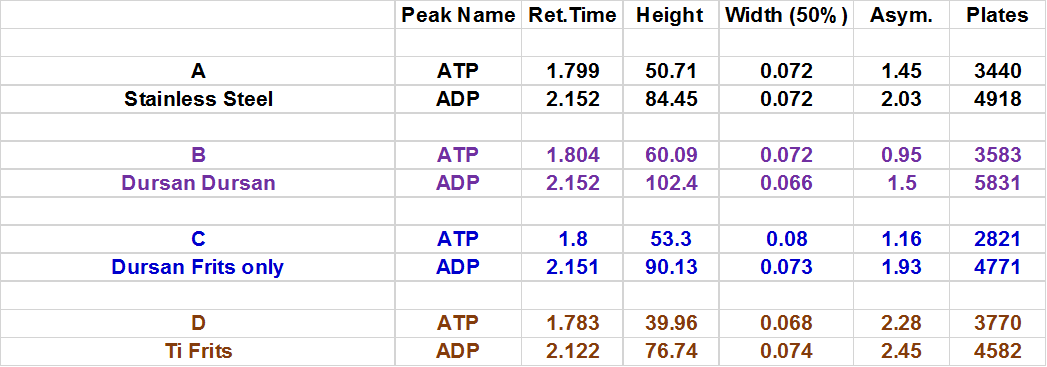

We injected the solution onto several coated and uncoated columns to compare peaks and overall performance. Materials were grouped into 4 tests, A, B, C, and D outlined below.

The Dursan coated surfaces improved peak resolution and peak shape significantly as compared below.

|

Group A: SS Frit & Column

|

B: Dursan Frit & Column

|

C: Dursan Frit, SS Column

|

D: TI Frit, SS Column

|

Proteins

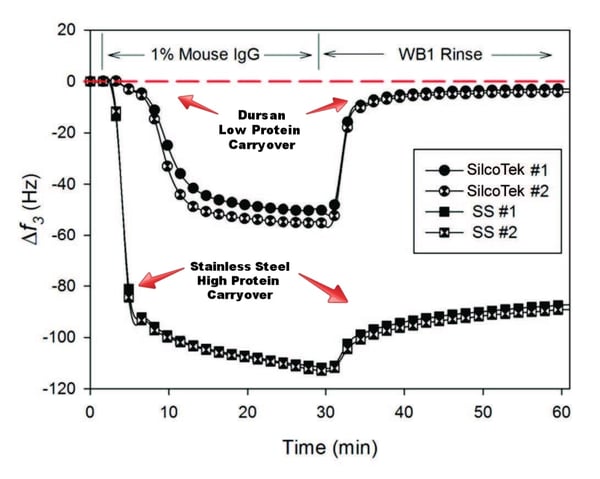

Comparative studies with Abbott Laboratories demonstrated the non stick feature of Dursan. Through our collaborative study with Abbott Laboratories, Dursan was shown to prevent non-specific protein binding and minimize protein fouling. Studies highlighting separations on HPLC peptide standard mixture, ribonuclease, cytochrome C, bovine serum albumin, and proteins show better response and minimum retention of the analyte on the surface, preventing cross contamination.

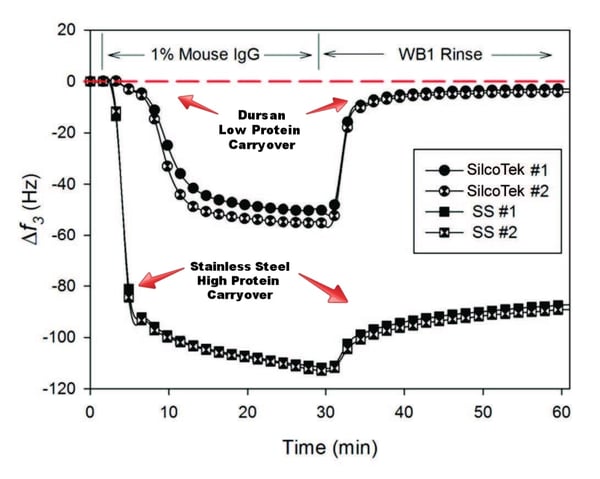

QCM-D analysis of coated and uncoated stainless steel surfaces show significant increase in protein mass on the stainless steel surface. The Dursan coated surface does not retain proteins, showing no increase in mass after washing with a non-ionic surfactant. This demonstrates the non stick feature of the coating.

Want to learn more about our protein study? Read the complete whitepaper.

Organic Molecules

Organic molecules like phosphates can perform poorly in stainless steel flow paths. We compared the performance of phosphate interaction in stainless and Dursan coated systems. Results show a significant improvement in performance.

- Adenosine triphosphate (ATP) provides energy to drive numerous processes in living cells

- It is typically converted to adenosine diphosphate (ADP) or adenosine monophosphate (AMP)

- Phosphates are well known to have severe peak tailing during HPLC analysis due to the phosphate-iron interaction

If you are interested in learning more about how SilcoTek coatings can enhance your HPLC applications, please reach out to us!

Want to try Dursan on your HPLC columns and flow path?