Material surface characterization capabilities of SilcoTek®

Material surface characterization capabilities serve an essential role in supporting SilcoTek® coating science and R&D efforts. The ability to thoroughly evaluate a surface is key to developing new inert barrier coating products, and plays an essential role in assisting customers with scale up and process troubleshooting.

Various surface characterization techniques enable SilcoTek scientists to study materials, analyze surface bonding mechanisms, and develop a deep understanding of surface properties.

SilcoTek® production technicians use material characterization tools in their daily QA/QC process to make sure all our inert, corrosion resistant coatings meet our quality standards and satisfy customer needs.

Last but not least, it is not uncommon for customers to work with R&D staff to provide characterization help with their specific substrates or coated parts as part of their product development.

In addition to the in-house characterization capabilities, SilcoTek® also enjoys convenient access to a wide variety of characterization techniques at the Pennsylvania State University (PSU), thanks to our physical proximity to the University’s main campus, and an established academic/industry relationship between PSU and SilcoTek®.

SilcoTek’s R&D scientists are certified users of many characterization instruments located at the Materials Characterization Lab (MCL) at Penn State University. Here are some of the tools we use to support our customer, products and processes.

What Tools Are Needed To Characterize A Surface?

Coating surface characterization starts with a capable and knowledgeable R&D team. Tool to help analyze the surface vary with application and need but here are a few tools we use to understand surfaces.

X-ray Fluorescence (XRF) Analyzer

In order to avoid process disruptions caused by incompatible substrates, SilcoTek uses a Thermo Scientific X-ray fluorescence (XRF) analyzer, a non-destructive elemental analysis tool, to identify any unfamiliar incoming metal substrates. Other coating companies may guess what the base metal is, we know what material we're coating!

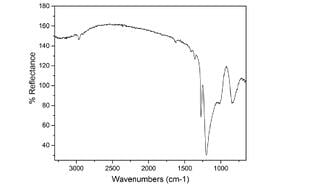

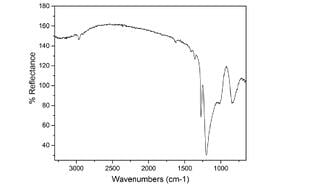

FTIR

Fourier Transform Infrared Spectroscopy (FTIR) uses a broad band infrared radiation as the excitation source to probe molecular structures of various chemical species in gas, liquid or solid state. The FTIR technique is used by SilcoTek’s technicians on a regular basis to perform the QA/QC duties, as well as by SilcoTek’s scientists to assist in their R&D projects.

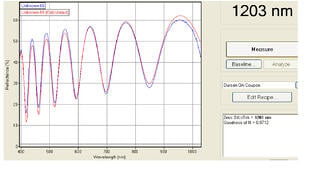

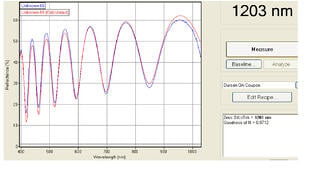

F20 Thin-film Analyzer

SilcoTek’s F20 thin-film analyzer (manufactured by Filmetrics Inc.) is a bench top tool that can be configured to measure thin film thicknesses (30Å to 350 mm), optical constants (n and k: refractive index and extinction coefficient) and transmittance. It is primarily used by SilcoTek as a quick, accurate and non-destructive way to measure surface thicknesses.

Surface contact angle measurement

Contact angle is the angle that a drop of liquid makes to its (usually solid phase) contacting surface. It is measured through the droplet, with the angle formed between the solid surface and the liquid meniscus near the line of contact. The contact angle gives an indication of the wettability of a surface to a liquid (usually water), and the value of the contact angle can vary with the volume of the liquid drop.

SilcoTek scientists rely heavily on the contact angle measurement in their research of hydrophobic and superhydrophobic surface development, where properly designed surface topography can bring out the extreme water-repellent property in a surface.

Contact angle measurement benefit to SilcoTek’s customers: ensure anticipated surface hydrophobicity/hydrophilicity as required by application; confirm successful surface bonding.

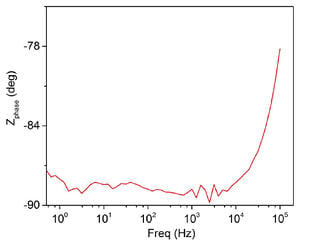

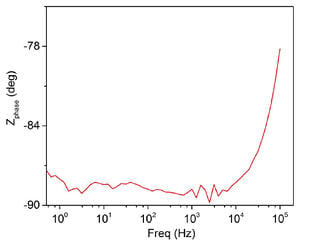

Electrochemical Impedance Spectroscopy (EIS)

Electrochemical impedance spectroscopy (EIS) is a mostly non-destructive and very useful tool to study and evaluate the performance of protective coatings on metal substrates. The measurement gives information such as resistance, capacitance, double layer capacitance and Faradaic impedance which are related to the performance and failure process of coatings.

EIS benefit to SilcoTek’s customers: provide corrosion performance evaluation of surfaces; help analyze failure mechanisms.

This blog posting highlights a range of materials characterization techniques available to SilcoTek®. It aims to help our customers understand the scope and capability of SilcoTek’s R&D activities, as well as to demonstrate how different tools can be used to facilitate SilcoTek in the development of more innovative solutions, to help our customers solve various application challenges. Easy availability of these tools also allows SilcoTek’s manufacturing team to keep a tight quality control on our inert coating products, thereby providing consistent and reliable products to all our customers.

This blog posting highlights a range of materials characterization techniques available to SilcoTek®. It aims to help our customers understand the scope and capability of SilcoTek’s R&D activities, as well as to demonstrate how different tools can be used to facilitate SilcoTek in the development of more innovative solutions, to help our customers solve various application challenges. Easy availability of these tools also allows SilcoTek’s manufacturing team to keep a tight quality control on our inert coating products, thereby providing consistent and reliable products to all our customers.