-

Coatings & Services

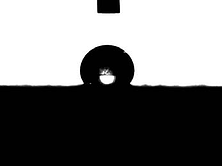

Our Coatings

Silicon Family

Silicon Oxynitride Family

Specialty Surface Family

Our Services

- Applications

- Resources

-

About Us

Careers

-

Contact

Contact

Address

225 PennTech Dr.

Bellefonte, PA 16823Phone: (814) 353-1778

Fax: (814) 353-1697Email: Service@SilcoTek.com

- Get a Quote