How to improve surface flow path hydrophobicity and oleophobicity in high temperature analytical applications? SilcoTek® answered the challenge by developing a high temperature moisture and oil repelling coating able to remain stable at temperatures of 300c and higher. Read the complete presentation.

SilcoTek coated a diamond like coating (DLC) with our unique hydrophobic and oleophobic coating and compared the moisture and oil stability after high temperature exposure. The SilcoTek coated surface performed significantly better in contact angle testing.

An Unexpected Result

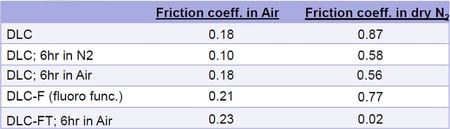

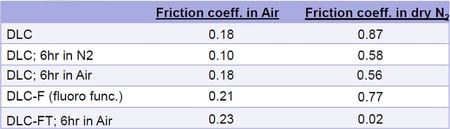

SilcoTek achieved significant improvement in hydrophobicity and oleophobicity compared to the uncoated DLC surface. More impressively, the new coating remained stable when exposed to high temperatures for and improved dry friction performance after oxidative high temperature exposure in dry N2. Results are tabulated below.

SilcoTek® coatings are the ideal hydrophobic and oleophobic solution to challenging environments. Applications include:

- Analytical sampling

- Analytical sampling

- Refining/petrochemical

- Oil and Gas exploration and transport

- Automotive

- Aerospace

SilcoTek's inert, high durability, high tolerance coatings can be applied to precision components used in the most demanding environments:

- Fuel injectors

- Nozzles

- Probes

- Separators

- Downhole tools

- Precision tubing

- Fritted filters

- Regulators

|

|

Learn more about SilcoTek hydrophobic coatings.

Read how SilcoTek coatings are used in many industries and applications: