Saving money? Improved Sustainability? Sounds great, right? Most manufacturing companies are always looking to save money on processing and increase sustainability. When we think of saving money in the semiconductor industry, we're primarily focused on improving yield and profitability. However, sub-fab operations are a costly but often ignored source of frequent replacement resulting from corrosion. What if we told you we have a solution to cut your costs in sub-fab operations?

How can SilcoTek’s coatings improve semiconductor sub-fab processes?

Everyone is always looking for up-and-coming technology to improve our processes, but what about the processes that aren't directly adding to your bottom line? Most of the money allocated to improve the overall semiconductor process is slated for the manufacturing process or new technologies. Let's take a look at how SilcoTek®'s coating solutions can help to improve your sub-fab operations.

What is the sub-fab process in the Semiconductor industry?

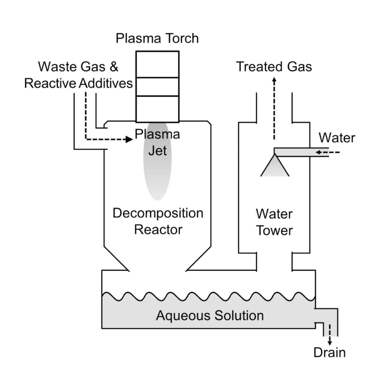

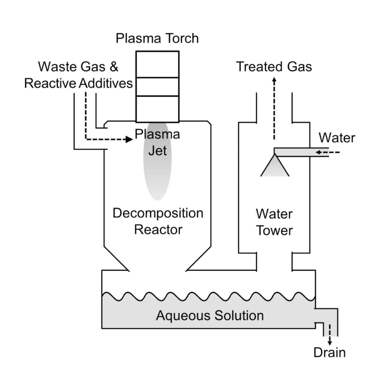

An example of a sub-fab process is a gas abatement or scrubber system. Below is a diagram of the flow path of a hybrid (wet and dry), point-of-use scrubber that is commonly used in the semiconductor industry. Gases such as silane (SiH4) and phosphine (PH3), as well as chlorine- and fluorine- containing etch gases are typical in the waste stream of the semiconductor manufacturing process. Due to their pyrophoric or toxic nature, there is a need for gas abatement systems, such as the scrubber below, to address both safety and environmental concerns. A high level overview: the dangerous gases flow through the reaction chamber, which burns those gases at a high temperature (about 1200o F). From there, the gas is flowed down to a wet tank where it is cooled and sent to the "wet side" of the scrubber. A water tower is then used to shower over the rising treated gas, removing any leftover particulate.

SilcoTek recently partnered with Samsung Austin to provide a solution to issues they were seeing with their scrubber systems. SilcoTek's coating was used to protect Samsung's decomposition reaction chamber by reducing corrosion. By utilizing SilcoTek's coating technology, Samsung was able to increase sustainability, reduce solid and contaminated water waste, improve uptime, decrease maintenance costs, and improve longevity of their parts. A controlled experiment compared the performance of their stainless steel and inconel uncoated parts to coated parts. Samsung saw a 300% increase in the longevity of the coated parts over the course of the experiment.

This isn’t the only problem in the semiconductor industry that our coating technology can help with, though! Reach out to us to learn more about how we can improve UHV pump down, dry etch processes, gas storage, vacuum pumps, among others.

Some other common parts that are often coated for sub-fab semiconductor applications are:

- Tubing

- Pipes

- Bellows

- Valves

- Fittings

Benefits

SilcoTek's amorphous coating technology has proven effective in increasing the longevity of parts in sub-fab systems. It starts as a small snowball and keeps growing and adding more benefits as it goes. By utilizing SilcoTek's high-purity coatings, you can significantly reduce the amount of process contaminants found in most scrubber systems. Less process contaminants means more conforming product. More conforming product means greater profitability. More profitability means more money to invest in your processes. Throughout this whole process, you will reduce your carbon footprint with substantially less solid waste.

- Increased longevity of parts, resulting in improved uptime

- Reduce metal waste in water and physical waste

- Better profitability due to continuous improvement of sub-fab operations

- Significantly decreased environmental impact

- Reduce maintenance and replacement costs

- Increased sustainability

Please join us as SilcoTek presents a webinar examining how SiltrideTM, SilcoTek's brand new amorphous silicon-oxy-nitride coating, extended the life of scrubber parts in gas abatement systems. Siltride is set for full release in early 2023 - stay tuned! Click below to register for the webinar on Thursday, August 25, 2022 at 11:00 AM EST.

To register for the webinar, click the link below!