Let's talk about corrosion and how it correlates to the dangers of fluorine-containing coatings. Corrosion is a constant challenge in many industries, leading to significant maintenance costs, operational downtimes, and safety hazards. To combat this, choosing the right corrosion resistant coating is crucial. Among the industry leaders, SilcoTek stands out with our advanced coating technologies that offer superior protection and performance. In line with growing environmental and health concerns, our commitment to providing PFAS (per- and polyfluoroalkyl substances) free coatings sets a new standard in corrosion prevention.

Understanding Corrosion and the Need for High-Quality Coatings

Corrosion can deteriorate metal surfaces, compromising the integrity and functionality of components in sectors like semiconductor, analytical, life sciences, energy, and more. To mitigate this, coatings play a vital role, creating a protective barrier that protects metal surfaces from corrosive elements such as moisture, salt, and chemicals.

SilcoTek is known for our innovative approach to materials science, offering a range of coatings designed to extend the lifespan and reliability of metal components. Our coatings are not only effective against many corrosive environments but also enhance performance in extreme conditions. Check out our chemical compatibility guide.

The Advantages of SilcoTek’s Corrosion-Resistant Coatings

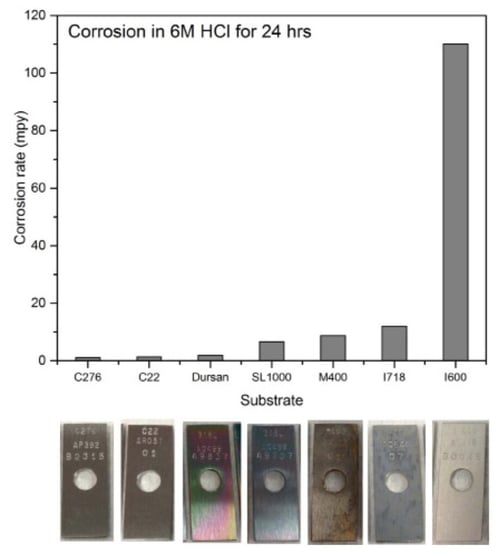

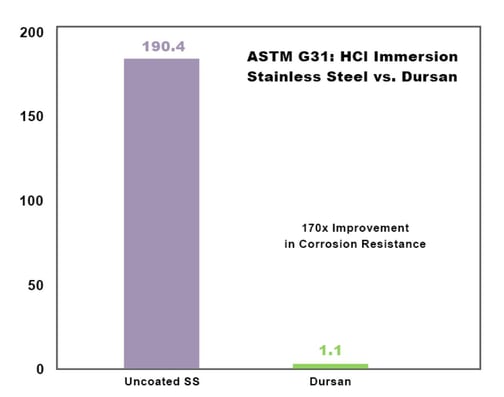

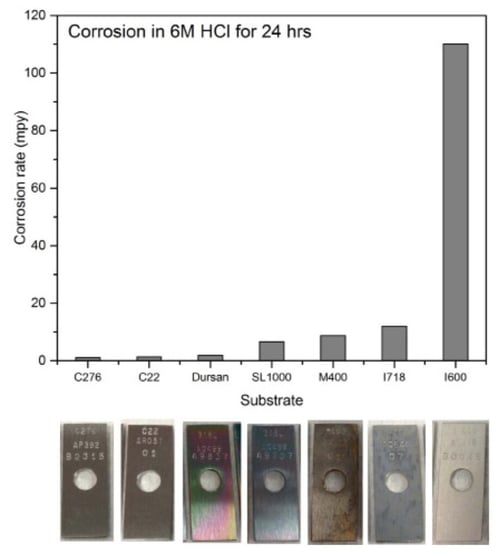

SilcoTek’s coatings, such as Dursan®, Silcolloy®, Siltride®, and Dursox™, are engineered to provide exceptional corrosion resistance. Here are some key benefits:

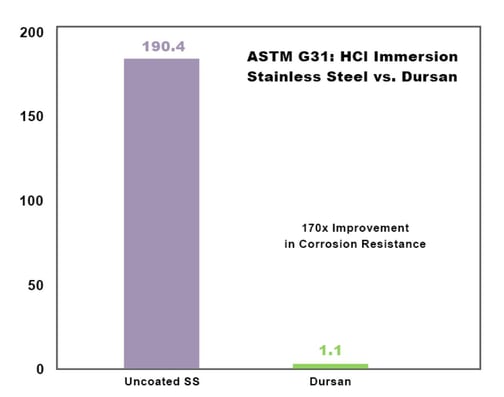

- Superior Protection: SilcoTek coatings are designed to withstand harsh environments, providing a thin, robust barrier against aggressive chemicals, saltwater, and high temperatures.

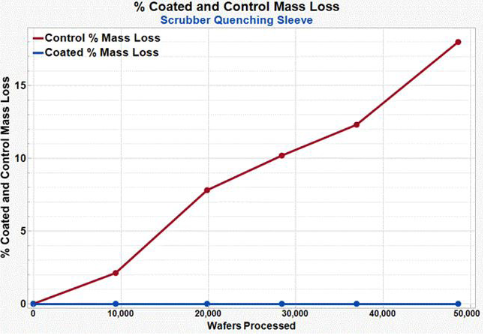

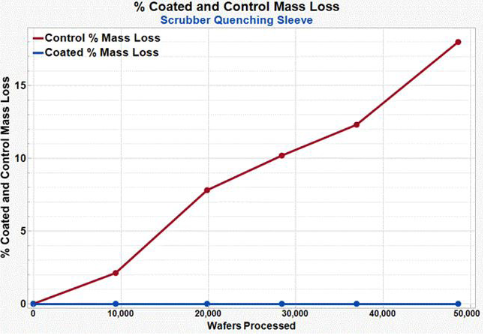

- Enhanced Durability: Our coatings significantly reduce the rate of wear and degradation of equipment, leading to longer service life for metal components.

- Chemical Inertness: SilcoTek’s coatings offer excellent chemical inertness, making them ideal for applications where metal contamination must be avoided.

- Versatility: Suitable for a wide range of industries, including oil and gas, chemical processing, semiconductor manufacturing, and more.

Embracing PFAS-Free Coatings

PFAS have been commonly used in various coatings due to their resistance to heat, water, and oil. However, fluorine-containing coatings remain in the environment and have been linked to serious health issues, including cancer and hormone disruption. As awareness of these risks grows, the demand for PFAS-free coatings has skyrocketed.

We have taken a proactive stance by offering PFAS-free coatings, addressing both performance needs and environmental responsibilities. Here’s why PFAS-free coatings are crucial:

- Environmental Safety: PFAS-free coatings do not persist in the environment, reducing the risk of long-term ecological damage.

- Health Protection: Free from harmful chemicals, these coatings pose no risk of long-term health issues for workers and end-users.

- Regulatory Compliance: As regulations tighten around the use of Teflon-like coatings, adopting PFAS-free coatings ensures compliance with current and future standards. See our statements on REACH, RoHS, and others below.

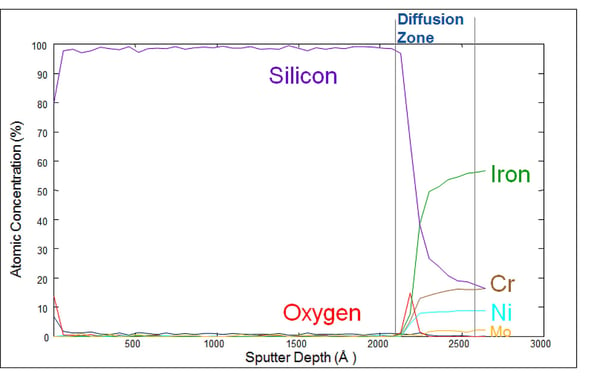

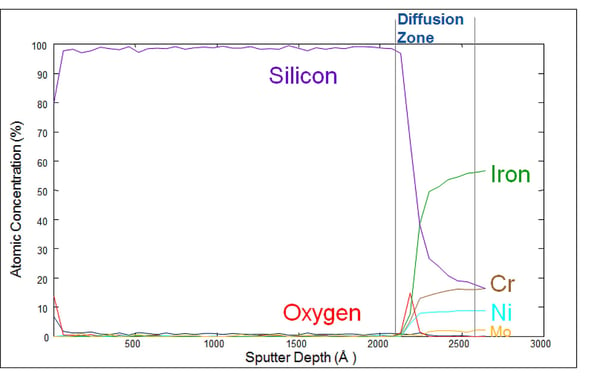

Most of our coatings contain silicon and carbon with a small amount of oxygen (mostly from oxide layers on the surface). We functionalize (or "dope") the surface for specific inertness performance but our Silcolloy coating and SilcoNert 1000 coatings are made of silicon with a native oxide surface only. Non-reactive silicon makes an excellent barrier which prevents contamination from the base metal, glass, or ceramic surface. The Auger Electron Spectroscopy (AES) diagram below of a SilcoNert surface shows the coating contains silicon and oxygen. Note the diffusion zone where the silicon is bonded to the stainless steel base.

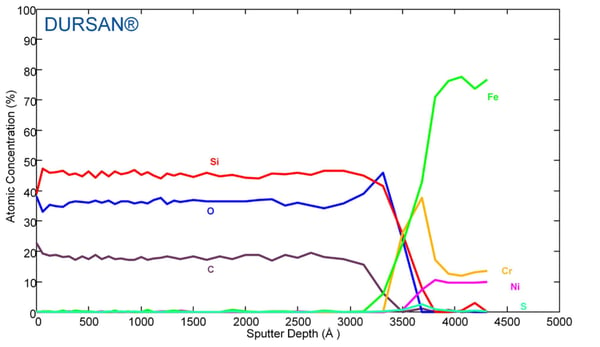

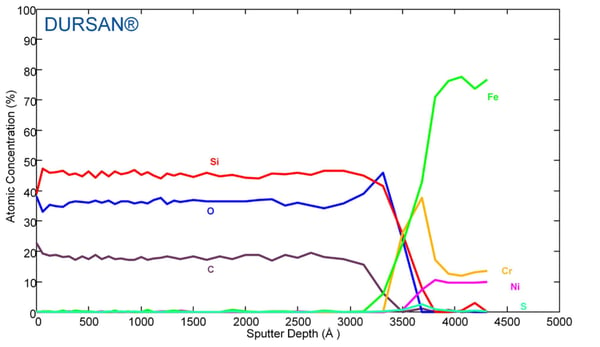

Dursan is a different coating consisting of silicon, oxygen, and carbon. The Auger plot below shows the coating depth and a similar diffusion zone to SilcoNert.

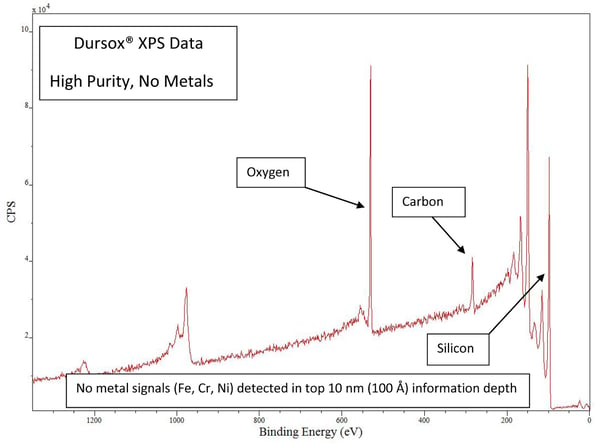

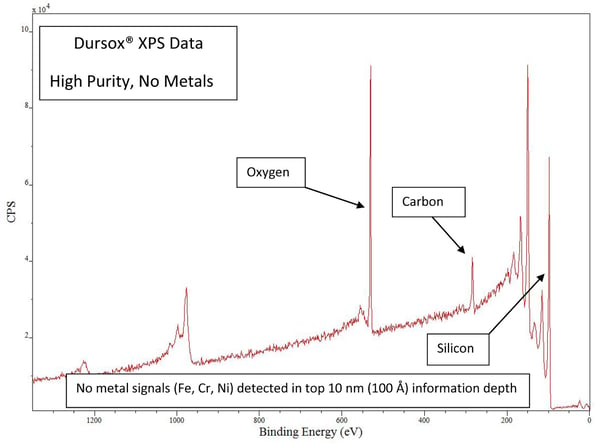

Dursox is similar to Dursan in that it contains oxygen, carbon, and silicon, although concentrations are different. The X-ray Photoelectron Spectroscopy (XPS) data below shows no metal signals in the coating.

SilcoTek’s commitment to sustainability is evident in our PFAS-free coating solutions. By leveraging advanced materials science, we have developed coatings that deliver top-tier corrosion resistance without the environmental and health risks associated with PFAS. These coatings provide effective corrosion protection that maintains the high standards of corrosion resistance that SilcoTek is known for, an eco-friendly composition that utilizes materials that are safer for both the environment and human health, and has a broad applicability that is suitable for diverse applications across multiple industries, ensuring that safety and performance are not compromised.

Real-World Applications and Success Stories

Industries worldwide are increasingly adopting SilcoTek’s PFAS-free coatings. For instance:

- Chemical Processing: Equipment exposed to harsh chemicals benefits from SilcoTek’s Dursan coating, which enhances durability and chemical resistance. Read the Case Study HERE.

- Oil and Gas: Components such as valves and pipelines protected with Silcolloy coating demonstrate extended service life and reduced maintenance costs. Read the Case Study HERE.

- Semiconductor Manufacturing: Preventing corrosion and contamination in scrubber systems with Siltride coating. Read the Case Study HERE.

Conclusion

SilcoTek’s corrosion resistant coatings represent a significant advancement in materials science, offering unparalleled protection and performance. By embracing PFAS-free solutions, SilcoTek not only addresses the growing environmental and health concerns but also sets a new benchmark in corrosion prevention. For industries looking to enhance durability while committing to sustainability, SilcoTek’s coatings provide the ideal solution.

Choosing PFAS-free coatings is a responsible decision that benefits both the environment and public health. Explore SilcoTek’s innovative coating technologies and join the movement towards safer, more sustainable corrosion prevention.

For more information on SilcoTek’s PFAS-free corrosion-resistant coatings, contact our coating experts to discover how you can protect your equipment while contributing to a healthier planet.