SilcoTek coatings help achieve part-per-quadrillion analysis. Here's why that's important.

Background:

Scientists from a wide variety of industries have been utilizing SilcoTek’s coating technology for decades to detect trace levels of compounds. Trace detection of VOCs for air quality, parts per million (ppm) and parts per billion (ppb) detection of sulfur compounds for natural gas and the beverage industry, and ppm levels of ammonia detection for various refinery and industrial applications are a few examples where the SilcoNert 2000 coating process allows for trace level detection that otherwise would not be possible.

|

In this blog post you will learn how to achieve part per quadrillion measurement of explosives and other chemicals .

- Methods used to detect at ppq levels.

- How to quickly detect trace level compounds

- How system design and an inert flow path contribute to improved trace level analysis

- Applications where part-per-quadrillion analysis is needed.

- How an inert surface is needed for ppq analysis.

- Keys to achieving effective and fast ppq detection.

|

Why do I care about part-per-quadrillion analysis?

There are some nasty chemicals out there that even a small amount of can be dangerous, deadly, or can impact the quality of products. When measuring part-per-billion levels of contamination, the environment, human health, and product quality improved. PPT measurement moved the bar forward in helping to detect and manage pervasive contaminants that led to chronic problems in health, pollution, and product yield. The same will be true when managing and realizing ppq analysis benefits. There are several areas of analysis even now that benefit from having the capability of consistent and reliable part-per-quadrillion analysis. Some examples are:

- Air quality monitoring. Sometimes it can be difficult to detect air pollutants especially when measuring from long distances. Having the ability to detect target contaminants at low levels give analysts the ability to identify sources of contamination and target remediation efforts.

- Soil contamination and dioxin detection. Dioxins are extremely dangerous carcinogens even at trace levels. The lower the detection level the safer our communities will be.

- PFCs, PFOA, and PFOS and other potential cancer causing chemicals. Many can be found in our environment at ppt and ppq levels.

- Adulterants in high purity gas. High purity gasses are used in many industries. Many businesses depend on ultra pure gas to achieve product yields needed to achieve profitable production levels. Semiconductor manufacturing for example is moving to 14 nm production and even smaller node architecture. At that level, even small amounts of contamination can impact product yield. Recent enhancements in detection capability has improved detection of SF6 in ultra-pure Ar to 750 ppq.

- Hazardous gas detection. Hazardous gasses like HF can be harmful even at very low levels. Low level detection improves systems meant to alert workers in refineries and chemical process industries.

- Explosive detection. Ultra low level explosive detection has many applications in homeland security and defense. Reliable ppq detection will help to improve airport screening and can improve forensic analysis.

- Chemical agent detection. Improved chemical agent detection can help military organizations find "bad actors" using chemical agents at greater range.

One Example of Effective PPQ Analysis, Explosives Detection

In 2011, the Naval Research Laboratory (NRL) released a review article about their work in developing equipment that is able to detect explosives at very low levels. At the time, they were able to detect TNT and RDX (types of explosives) at parts per trillion levels at a wide variety of humidity levels. They commented that “The NRL test bed is the only one of its kind in the world to provide quantitative results for explosive vapors over such a wide concentration range.” This type of equipment can be useful for troops on the ground for improvised explosive device (IED) detection and at security check points around the world.

Discussion and data:

Pentaerythritol tetranitrate (PETN) is an explosive that has been used widely in IEDs and is notoriously difficult to detect. These difficulties can be attributed to PETN’s low vapor pressure at room temperature as well as its tendency to breakdown or decompose at higher temperatures rather than volatilize. Current techniques for detecting low levels of PETN involve vapor sampling with sorbent filled sampling tubes followed by concentrating the vapors to be measured by GC or HPLC. These techniques require over 4 hours of sampling time in order to get accurate measurements. The sample preparation and testing time then extends the measurement a few more hours. The TESTbed developed by the NRL can perform these tests with 10 minutes of sampling time for difficult molecules like PETN, and 1-2 minutes for molecules that are easier to detect such as TNT and RDX. The TESTbed method also requires minimal sample preparation. The NRL was able to reliably measure 260 parts per quadrillion of the PETN explosive.

How to detect at ppq levels?

Realizing the human health, environmental, and business benefits of ppq detection takes effort. It's not like you can turn the ppt "volume knob" up to 11 and get good results. It takes improved systems and techniques to achieve reliable ppq detection.

Realizing the human health, environmental, and business benefits of ppq detection takes effort. It's not like you can turn the ppt "volume knob" up to 11 and get good results. It takes improved systems and techniques to achieve reliable ppq detection.

Types of detection systems vary and include:

One Key to Achieving ultra low level detection

Robust equipment design and meticulous sample preparation play a large role in achieving ultra low level detection limits. Equipment costs can run into hundreds of thousands of dollars for some instruments. All that expensive equipment won't achieve results without improving the sample flow path. It's vital to develop highly robust procedures based on well researched methods. One key area that must be addressed and managed? Adsorption and chemical interaction of the flow path surface with the target analyte. Without thoroughly managing flow path inertness it will be unlikely that you'll achieve ppq or even ppt, or ppb level results. Some tips for managing the flow path are:

- Understand the reactivity of each component material in the flow path for the target test regime. A material capable of ppm analysis may not be appropriate when testing at ppq levels.

- Prepare the surface using non reactive chemicals that will not leave trace contaminants.

- Focus on sample prep and adopt a rigorous method.

- Use proven non-reactive materials in the flow path. Don't forget to test & select sealing materials that will not adsorb or react with test analytes.

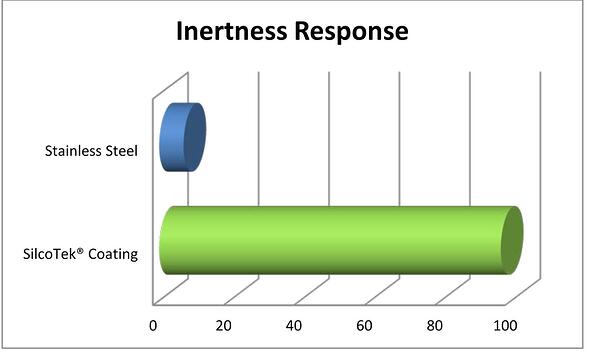

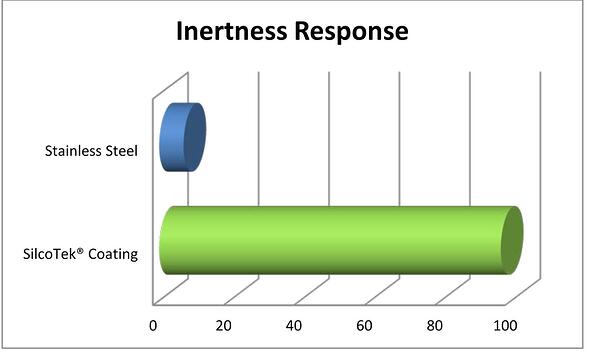

- Select an inert material like SilcoNert® to prevent interaction with the test analyte. SilcoNert is proven in part-per-quadrillion applications. Read about the test here. SilcoNert does not interact with reactive chemicals, allowing nearly all the analyte to reach the detector and improving response dramatically when testing trace compounds at ppq levels.

Conclusion:

SilcoNert 2000 coated sample flow paths prevent interaction and adsorption of reactive trace compounds, allowing for ppq levels of detection. Some difficult to detect compounds, like PETN, do not volatilize easily, and may be present in trace amounts in the atmosphere. The NRL has developed a method to quantitatively detect this explosive with 10 minutes of sampling time, which is orders of magnitude less than traditional sampling and measurement methods. This method will allow for rapid detection of difficult to detect trace compounds, like explosives, at critical locations like fenceline monitoring stations, in warzones to protect soldiers from IEDs and at ports of entry to detect hidden or illegal cargo trying to enter the country.

Have a question about trace level detection and how SilcoTek coatings can improve the performance of your sample flow path and instrumentation? Contact our Technical Service Team to discuss your application. Or join us on LinkedIn to ask the experts about your coating needs.

Reference:

1. Mullen, M., Giordano, B.C. “Part per quadrillion quantitation of pentaerythritol tetranitrate vapor using online sampling gas chromatography–mass spectrometry”. Journal of Chromatography A. 2019. In press.

Realizing the human health, environmental, and business benefits of ppq detection takes effort. It's not like you can turn the ppt "volume knob" up to 11 and get good results. It takes improved systems and techniques to achieve reliable ppq detection.

Realizing the human health, environmental, and business benefits of ppq detection takes effort. It's not like you can turn the ppt "volume knob" up to 11 and get good results. It takes improved systems and techniques to achieve reliable ppq detection.