Stainless steel sample cylinders are essential for collecting, transporting, and storing gas or liquid samples in analytical, environmental, petrochemical, and process monitoring applications. Their metal construction is crucial for safety and durability, but also poses serious challenges: contamination, reactive compound loss, adsorption, and corrosion. SilcoTek CVD coatings provide the performance boost needed to keep sample integrity high and costs low, while maintaining important regulatory compliance such as DOT and TPED.

Why SilcoTek CVD Coatings Work

Traditional strategies to mitigate unwanted chemical interactions within sample cylinders such as electropolishing or passivation often fall short because these processes still result in exposed metal. Coupled with the extremely high surface area of sample cylinders, exposed metal is almost guaranteed to adsorb and catalyze chemical compounds within gas samples. SilcoTek’s chemical vapor deposition (CVD) coatings solve these problems by:

- Creating a molecularly bonded barrier layer on 100% of part surfaces that is uniform, ultra‐thin, and inert.

- Being non-line-of-sight in application: the coating conforms evenly inside valves, welds, or complex internal geometries.

- Maintaining the mechanical strength and robustness of the base stainless steel while providing chemical inertness. Coated sample cylinders are still DOT and TPED certified.

- Eliminating reactive or catalytic sites on the metal surface so that samples aren’t lost (due to adsorption) or altered (due to reactions).

Coating Benefits for Sample Cylinders

1. Improved Sample Integrity & Reduced Adsorption

Reactive or trace compounds (e.g. H2S, sulfur compounds, mercaptans, ammonia) are often lost when surfaces adsorb or react with samples. Cylinders coated with SilcoTek-coatings (for example SilcoNert® 2000 or Dursan®) offer inert surfaces that minimize these losses, improving accuracy and detection limits even better than PTFE.

SilcoNert coated sample cylinders reduce adsorption by creating a barrier between the cylinder and the sample.

SilcoNert coated sample cylinders reduce adsorption by creating a barrier between the cylinder and the sample.

2. Corrosion Resistance & Durability

Sample cylinders often carry corrosive or aggressive gases or liquids (e.g. HCl, acidic condensates, moisture). The coatings protect against material degradation, extending cylinder lifespan and reducing risk of contamination from metal corrosion or leaching. SilcoTek’s CVD coating process does not degrade the mechanical integrity of metal sample cylinders and can withstand as much pressure as the metal itself.

Corrosion test results of coupons in 6M HCl for 24 hours. The Dursan and Silcolloy-coated stainless steel coupons held up exceptionally well in an aggressive acidc environment.

3. Longer Hold Time & Stability

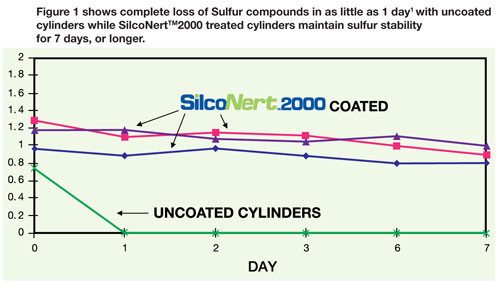

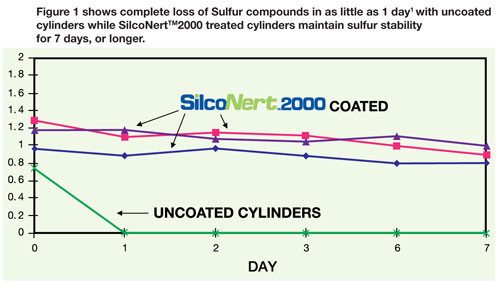

Because coated internal surfaces are inert, sample degradation over time is reduced. This means samples can be held or transported for longer periods without significant loss or alteration, which is critical for remote sampling, emissions monitoring, or field testing.

SilcoNert 2000 coated sample cylinders give the analyst the flexibility to hold samples longer, even at concentrations as low as 11 ppb.

4. Cleaner Handling, Less Maintenance

With inert and smooth surfaces:

- Cleaning cycles are less frequent.

- Sample carryover between uses is minimized.

- Internal surfaces resist fouling, moisture retention, or buildup of residues.

Choosing the Right Coating for Your Cylinder

| Coating |

Best For |

Key Advantages |

| SilcoNert 2000 |

Trace reactive compounds (sulfur, ammonia), very low background, high sensitivity work |

Extremely inert, low adsorption, excellent for low-ppt/ppb analyses |

| Dursan |

General chemical compatibility across broad pH, some acid / base exposure, robustness |

Good corrosion resistance, resilient, compatible with many sample chemistries |

Real-World Impact

Here are some typical improvements customers see when switching to SilcoTek-coated sample cylinders:

- Substantial reduction in sample compound loss - e.g. trace sulfur compounds show better recovery vs uncoated cylinders.

- Hold times increased from hours to days or longer for sensitive analytes.

- Lower blank/background levels in analyses.

- Fewer maintenance & reconditioning events for cylinders.

- Greater confidence in analytical results, especially for regulatory or compliance work.

The Bottom Line

Sample cylinders may seem simple, but with their high surface area and the length of time they are used to store often volatile chemical samples, they are the #1 source of adsorption that causes inaccurate analytical results later in the process. Every bare metal surface that gas samples touch has the potential to compromise the sample, undoubtedly with reactive compounds like H2S, mercaptans, mercury, and more. SilcoTek’s CVD coatings like SilcoNert 2000 and Dursan turn ordinary stainless steel cylinders into high-performance sample vessels: chemically inert, durable, low adsorption, and corrosion resistant. If you want clean, accurate, dependable sampling - from field collection through to lab analysis - coated cylinders are a smart investment.

Have questions about your sample cylinder application? Reach out to our experts and we can help recommend specific coatings based on the chemicals you’re sampling, holding times, pressures, and environmental conditions.