Air Monitoring Vehicle

Air Monitoring Vehicle

Image from Connecticut's Official Government Website

Announced in a May 1, 2023 article by Fox61 news, Connecticut's Department of Energy and Environmental Protection (DEEP) introduced the Geospatial Measurement of Air Pollution (GMAP), a mobile air quality monitoring vehicle designed to travel across the state and collect real-time air quality data. With an investment of $300,000, the vehicle, a Ford Explorer Hybrid, carries sensitive equipment capable of detecting 16 air pollutants and weather data. Funded heavily by an EPA grant, this advanced technology aims to ensure safe air quality, especially in communities burdened by poor environmental conditions, as highlighted by EPA New England Regional Administrator David W. Cash.

The vehicle will operate at least once a week, already having responded to air quality complaints. Jake Felton, Director of DEEP's Air Quality Enforcement Division, outlined plans to use the vehicle's capabilities to focus on historically overburdened environmental justice communities, starting with East Hartford and Hartford. This targeted approach aims to address and improve air quality concerns in these areas, signifying a proactive step toward environmental justice and community health.

This article from Connecticut's Official State Website is a great resource to learn more information about how this new air monitoring vehicle operates. The vehicle measures pollutants such as BTEX compounds, ammonia, VOCs, and sulfurs, among others. These types of compounds are notoriously difficult to measure due to their adsorptive nature in sampling systems. SilcoTek coatings can help to alleviate those headaches. Here's an example of what we mean:

Ammonia

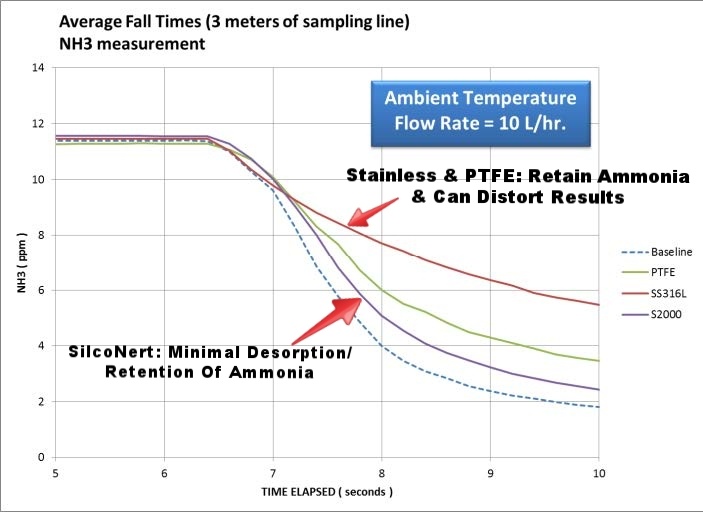

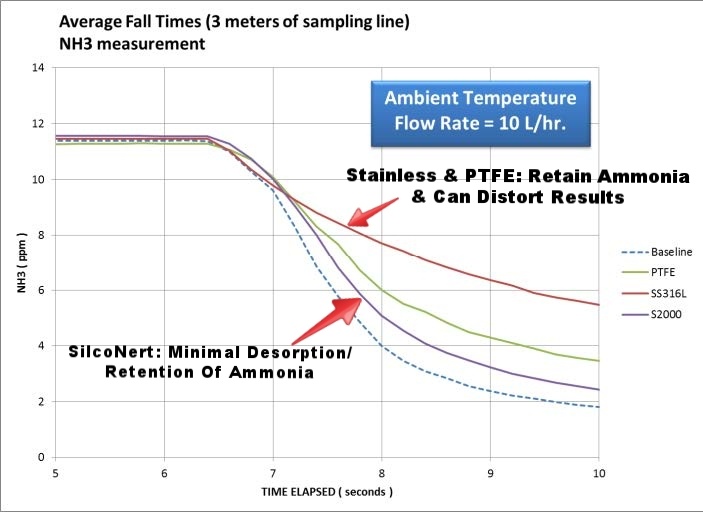

Untreated flow paths like bare stainless steel and even PTFE-lined flow paths will hold onto an ammonia sample, causing delayed readings or artificially low readings. As the NH3 accumulates in the system flowpath, it will eventually desorb or leach into the sample stream, resulting in high readings. The back and forth adsorption and desorption ultimately makes testing less and less relevant to real world conditions. At minimum, a reactive flowpath will reduce test efficiency while the analyst struggles to recalibrate or purge the flowpath. At worst, a reactive flowpath will skew test results, jeopardizing regulatory compliance or may lead to process stream contamination or reduced yield. This can be especially important for air quality testing.

Fast response means less chance of a cumulative build-up of reactive compounds in the system and fewer test errors. The key to fast response? A surface that does not retain or adsorb the analyte. The graph below shows SilcoNert 2000 does not adsorb the NH3 analyte, so there's little resulting desorption and disruption to analytical results.

SilcoNert response time to baseline is the shortest of the 3 surfaces compared:

- Stainless Steel: 33 seconds

- PTFE: 18 seconds

- SilcoNert: 9 seconds

- Baseline: 6 second

How SilcoTek Helps

SilcoTek coatings play a crucial role in air monitoring by enhancing the performance and reliability of the instruments and sensors used in this process. Here's how SilcoTek coatings contribute to air monitoring:

-

Improved Sensitivity and Accuracy: Coating sensitive components in air monitoring devices with SilcoTek coatings minimizes interactions between the monitored air and instrument surfaces. This inertness reduces interference, leading to more accurate and sensitive measurements of air quality parameters.

-

Reduced Contamination: SilcoTek coatings create an inert surface that repels impurities and minimizes sample carryover, ensuring that monitored air samples remain uncontaminated during the analysis process. This is crucial for obtaining precise and reliable air quality data.

-

Corrosion Resistance: In environments with varying air compositions or potentially corrosive elements, SilcoTek coatings protect instrument components from degradation and corrosion. This ensures the longevity and performance of the monitoring devices, even in harsh conditions.

-

Enhanced Durability: Coated components exhibit improved durability, enabling them to withstand the stresses of continuous use in air monitoring applications, thereby extending the lifespan of the monitoring equipment.

-

Maintaining Calibration and Performance: Coated surfaces help maintain calibration over time, ensuring consistent and reliable performance of the monitoring instruments.

By applying SilcoTek coatings to various parts and surfaces within air monitoring equipment, these coatings contribute significantly to the accuracy, sensitivity, and longevity of the devices, ensuring the collection of reliable and high-quality air quality data for analysis and decision-making.

Coat The Entire Flowpath

A short piece of tubing may not seem like a test killer, but the results prove that seemingly little things like an inert surface in the flowpath can make the difference between garbage results and consistent, robust results. Other components you should coat are:

- Fritted filters: Each frit has a huge surface area. Not coating frits can lead to similar performance issues.

- Regulators: Although less surface area, they too can retain analytes, like NH3, distorting calibration gas integrity and leading to calibration errors.

- Valves & fittings: As detection limits move from part-per-million to part-per-billion sensitivity, even small fittings and valves can retain and distort results.

- Sample cylinders: Internal surfaces of sample cylinders are quite rough, making ideal conditions for adsorption of ammonia.

By applying SilcoTek coatings to the appropriate components of analytical instruments, such as gas chromatographs (GC), mass spectrometers (MS), or gas analyzers, researchers and analysts can achieve more accurate and reliable measurements of air pollutants. As with any analytical measurement, reliable results are of utmost importance, it is especially important when community health is at risk. Hopefully, continued advancements in this technology will populate more of these types of monitoring systems around the globe.

Want to learn more about how SilcoTek coatings can help your monitoring applications? Contact us today!

Air Monitoring Vehicle

Air Monitoring Vehicle