I had a conversation with our Life Sciences Technical Sales Representative, Patrick Dick, about some of the common questions he gets from his customers. Let's take a deeper dive into protein sticking, hydrophobicity, and metal ion leaching in medical applications. Understanding these processes is essential for developing safer and more effective medical devices.

Stainless steel in vitro diagnostic (IVD) probes coated with Dursan resist non-specific adsorption of proteins and other bodily sample media. Customers report improved diagnostic speed and accuracy along with greater ROI. Coated probes require significantly less maintenance and replacement compared to uncoated or fluoropolymer-coated (e.g. PFA) probes.

Protein Sticking

Protein adsorption, or sticking, occurs when proteins in biological fluids adhere to the surfaces of medical devices. This can cause device malfunction in sensors and diagnostic tools, biofouling that leads to protein films that develop into infections, and the body recognizes proteins as foreign and triggers an immune response.

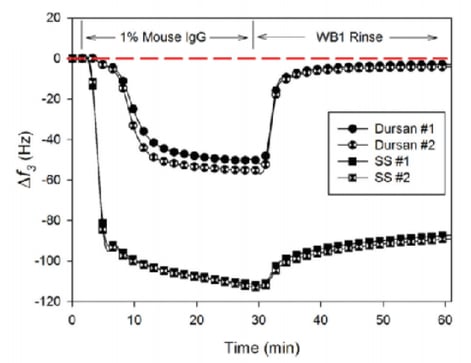

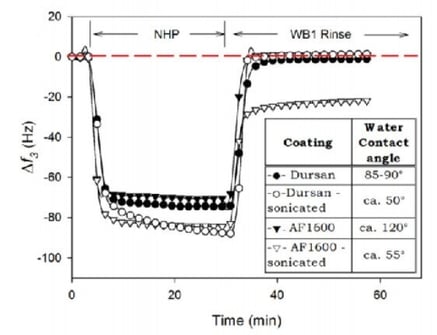

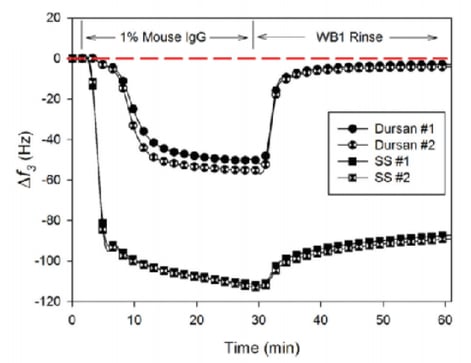

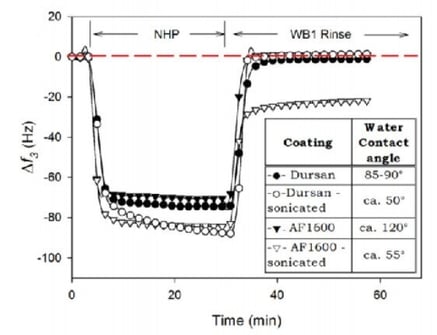

In 2021, we did a case study with Abbott Labs on reducing protein adhesion on medical diagnostic equipment with Dursan® coating. To look for increased protein resistance, the Abbott group performed tests on a Quartz Crystal Microbalance with Dissipation monitoring or QCM-D, which is a highly sensitive mass sensor that can detect mass uptake or release by interpreting changes in the quartz resonance frequency. The sensors were coated in a thin layer of 316L grade stainless steel and then coated via chemical vapor deposition with SilcoTek’s Dursan process. After treating the QCM-D sensors with a protein solution and gauging the protein adhesion, the following was established. As seen in Image 1 below, a combination of Dursan coating and a wash step containing a non-ionic surfactant facilitated 100% removal of tested proteins. Shown in Image 2, comparison studies between Dursan and AF 1600 (a competitive fluoropolymer coating) showed that sonication degraded the protein resistance properties of the AF 1600 due to delamination, but had no negative impact on Dursan demonstrating the coating’s superior adhesion and more robust performance. This study illustrates what an inert coating can do for stainless steel equipment in any protein adhesion environment, creating fewer false positive tests due to protein carryover and contamination.

Image 1:The combination of Dursan coating and nonionic surfactant in the wash solution led to effective reduction of protein loss to the sensor surface.

Image 2: Wear resistance test using sonication showed robustness of the CVD Dursan coating. In contrast AF1600 coating lost efficiency due to coating delamination.

Hydrophobicity and Contact Angle

Hydrophobicity refers to a surface's tendency to repel water. SilcoTek's inert high temperature barrier coatings enhance hydrophobic interaction between critical flow path surfaces and your product. Dursan coating improves moisture repelling properties of stainless steel, glass, and ceramic surfaces by 60% or more, minimizing wetted surface effects. Coating critical flow path surfaces can help process engineers and analysts manage moisture and improve results.

Below are the contact angles for some of our coatings:

Applications for super hydrophobic surfaces in medical diagnostics include:

- Needles

- Tubing

- Lab-on-chip diagnostics

- Antibacterial/infection prevention

- Blood compatible diagnostic tools

- Cell bioanalysis surfaces

Metal Ion Leaching

In a series of studies investigating metal ion leaching in different solvents, SilcoTek's researchers found that titanium, 316 stainless steel, C-22 Hastelloy, and MP35N alloys exhibit varying degrees of corrosion and metal ion release, which is highly relevant for medical applications. Titanium showed no ion leaching in ultrapure DI water and acetonitrile, making it a suitable material for medical devices in contact with these solvents. However, methanol caused significant leaching in titanium, emphasizing the importance of solvent choice. Stainless steel and Hastelloy experienced notable metal ion leaching in both methanol and DI water, with Hastelloy also showing intensified corrosion in water. These results highlight the potential risks of using these materials in medical settings where exposure to these solvents might occur, potentially leading to contamination and adverse biological effects.

MP35N, a nickel-cobalt-based alloy gaining popularity for its biocompatibility and corrosion resistance, demonstrated low metal ion leaching in methanol and acetonitrile, with acetonitrile being the most benign solvent. The findings underscore the critical need for careful selection of materials and coatings in medical applications to minimize metal ion contamination and ensure patient safety. Coatings such as Dursan, Silcolloy, and Siltride were shown to effectively prevent ion leaching, offering a promising solution to enhance the biocompatibility and durability of medical devices.

Image 3: Metal ions leached into methanol solution after one month of soak time. The coated samples were

Image 3: Metal ions leached into methanol solution after one month of soak time. The coated samples were

all at or near baseline levels of the methanol in the bottle.

Here are some commonly coated medical diagnostic components:

- Needles

- Probes

- Narrow and wide bore tubing

- Valves

- Regulators

- Fittings

- Sintered metal frits

- Glass surfaces like slides and liners

- Rotary valves

- Other stainless steel, alloy, glass & ceramic surfaces

FDA Compliance

The United States Food and Drug administration (FDA) does not formally "approve" coatings or other materials for food or bio/pharmaceutical contact. Rather, the FDA regulates coatings via the Code of Federal Regulations (CFR), specifically 21 CFR 175.300 which lists what raw materials are acceptable and unacceptable for the formulation of coatings. It is then up to the coating supplier to self-regulate to ensure that they are using raw materials that are acceptable.

According to the FDA, a coating must:

1) Pass the solvent extraction tests listed in 21 CFR 175.300.

2) Contain no heavy metals.

3) All coating components must conform to the materials listed by the FDA in order to be compliant.

These stipulations are also required for NSF/ANSI 51 certification. Dursan® successfully meets these requirements and is therefore FDA compliant. Read Our NSF Certification

With respect to pharmaceutical applications, our data suggest that Dursan® does not "alter the safety, identity, strength, quality, or purity of the drug product beyond the official or other established requirements" per 21 CFR 211.65.

Nevertheless, we strongly encourage customers to test the use of Dursan® in their specific application to verify that performance requirements are met and the customer's production processes and outputs can continue to meet FDA approval guidelines.

Biocompatibility

The United States Pharmacopeia and National Formulary (USP-NF) is a non-profit organization responsible for testing materials (usually single use plastics) for bio-toxicity. The goal of the testing is to be sure no toxic materials will be extracted when a product comes in contact with human tissue or injectable drugs or other products manufactured relating to healthcare, pharmaceuticals, or medical devices.

Class VI testing has the most stringent criteria and involves 3 tests that evaluate reactions for toxicity in tissue. Passing the test means the material is not toxic and does not leach potentially harmful substances into fluids or tissue.

Dursan passed all toxicity tests while maintaining superior inertness, durability, and corrosion resistance. Dursan exhibited no additional reaction or toxicity when compared to an inert blank sample. View the Class VI certification.

Have questions about SilcoTek's coatings or how we can fit into your application? Please contact our experts!