In this blog post we discuss how non reactive, high purity coatings like Dursan improve in vitro diagnostic probes and needles.

In this blog post we discuss how non reactive, high purity coatings like Dursan improve in vitro diagnostic probes and needles.

SilcoTek® Coatings Improve In Vitro Diagnostic Probes

SilcoTek’s coating technology has a long history of improving performance of very narrow

and precise instrumentation, and our customers who manufacture probes understand

the importance of proper surface technology. The Dursan® process is a chemically inert,

silicon-based coating that improves corrosion resistance and reduces protein carryover

promoting more accurate test results as well as more thorough cleaning, disinfection,

and sterilization processing. SilcoTek’s Dursan technology has been rigorously tested

to ensure proper performance and to earn an NSF Certification and a USP Class VI

Certification.

|

In this blog post you will learn:

- How SilcoTek's unique non-line-of-sight coating technology coats the inner bore of precision needles, probes and small bore tubing to improve anti-hemolytic and anti-sticking properties.

- Learn about the benefits of coating IVD probes in medical diagnostic applications.

- Get comparative performance data on how Dursan prevents cross contamination and improves analytical sensitivity.

|

Benefits

SilcoTek coatings offer unique performance benefits. Because they're both non reactive and durable they're able to stand up to harsh cleaning environments while delivering reliable analytical performance. And because coatings like Dursan resist protein binding and fouling there's significantly less cross contamination.

- Improve Cleaning - Dursan’s inert barrier reduces contamination and buildup of biological material, while making standard rinsing easier and more effective.

- Easy Integration - Run processes as normal while enjoying the coating benefits. SilcoTek coatings hold up to steam and conform to parts, creating no appreciable changes to tolerances or surface morphology.

- Enhance Performance - Improve diagnostic sensitivity by reducing non-specific protein binding and carryover.

- Increase Efficiency - By improving corrosion and contamination problems, cleaning will be more effective and parts will need to be replaced less often.

- Reduce Contamination - An inert barrier will prevent contamination commonly caused by the sample, the reagent, or ions leaching from probe metal.

Enjoying our content? Subscribe to our blog!

Solving problems

Apply Dursan® to existing component designs to improve corrosion resistance and analytical performance. Dursan is a micro thin precision coating that minimally impacts component dimensions, making it an ideal coating for small bore tubing, needles, and probes. SilcoTek® solves common issues with probes like:

- Poor performance caused by carryover of proteins.

- High cost due to corrosion related component replacement, especially from bleach.

- Contamination from leaching of metal ions out of equipment.

- Poor analytical sensitivity for challenging samples.

- Downtime caused by frequent maintenance and cleaning.

Learn more about how SilcoTek® coatings can solve problems in your application.

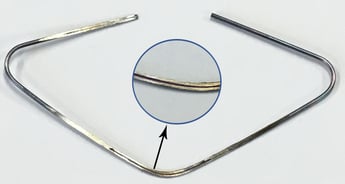

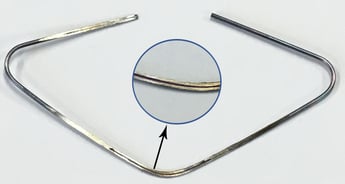

How SilcoTek Coats Small Bore Tubing

Our patented coating process fills the inner bore of the tubing, needle, or probe surface with our silicon based coating chemistry. The coating then binds to the surface during processing to make a uniform silicon barrier.

We proved coating aspect ratio capabilities by coating a 1/16" OD, .4mm ID tube with multiple bends both internally and externally. After coating, the tube was cut open to examine the coating at the center-most point inside the tube. In addition to the external coating on the tube, a quick visual inspection shows the vibrant purple-colored SilcoTek coating inside the narrow bore.

Coating Performance Data

At SilcoTek® we test our coatings and then test again! Our R&D Team is dedicated to enhancing our coating performance and improving your products. We've got lots of coating test data to share with you. In fact we wrote an e-book dedicated to just coating test data. You can get your free copy by clicking the button below.

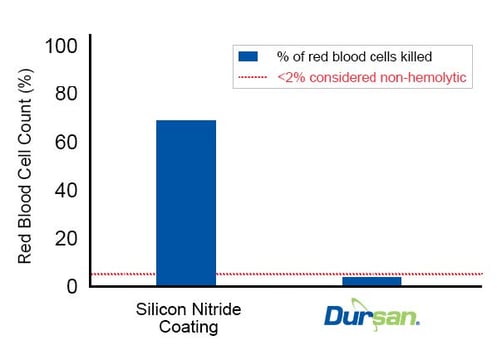

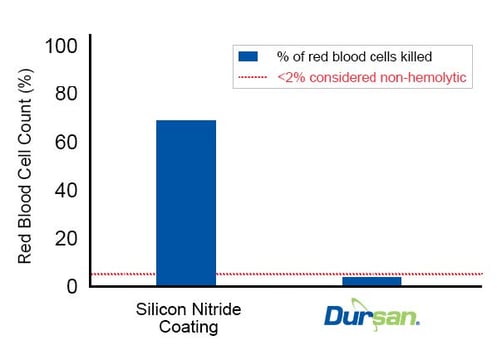

Improve Anti-hemolytic and Anti-sticking Properties

SilcoTek’s Dursan® coating is anti-hemolytic, achieving a customer’s goal of <2% red blood cells killed from a human blood sample. Stainless steel is typically 5-10% hemolytic but lacks Dursan’s inert, non-stick properties. A competitive coating tested as highly hemolytic, killing over 62% of red blood cells.

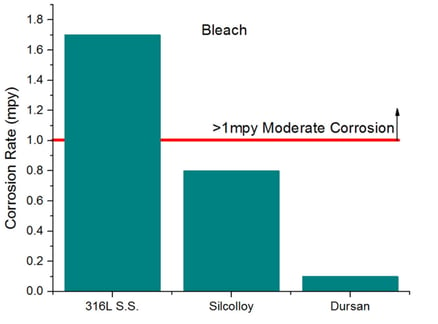

Prevent Bleach Corrosion and Variability

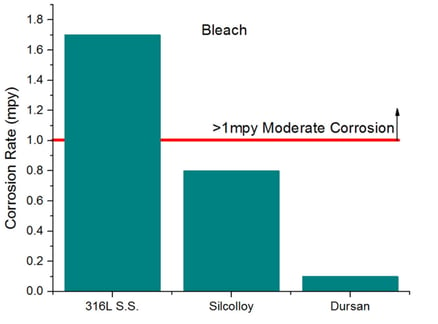

ASTM G31 72 hour comparative bleach immersion studies prove that Dursan significantly reduces the risk of corrosion in diagnostic probes, thus reducing any variability.

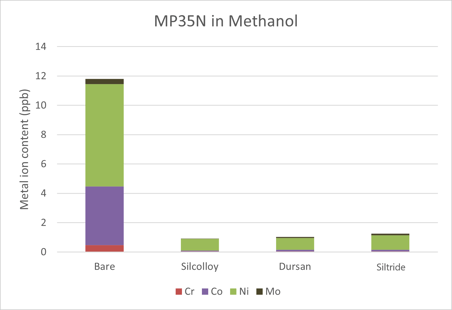

Reduce Metal Ion Leaching and Contamination

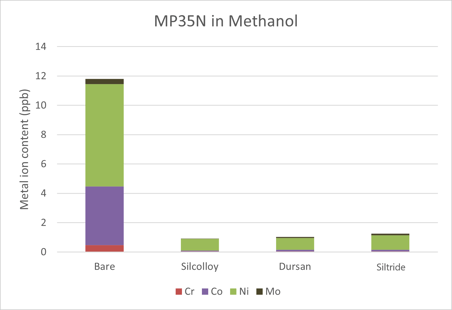

SilcoTek® measured metal ions leaching in methanol after a month of soaking to compare MP35N and SilcoTek coatings performance. Coated samples all showed less than 1 ppb metal ion content leached into the methanol, while MP35N measured significantly worse at roughly 12 ppb of metal ions.

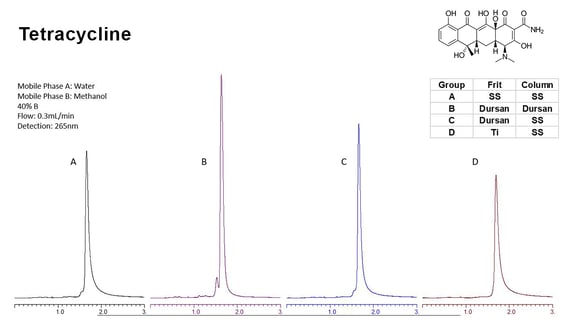

Ensure Sensitive, Fast and Accurate Analysis

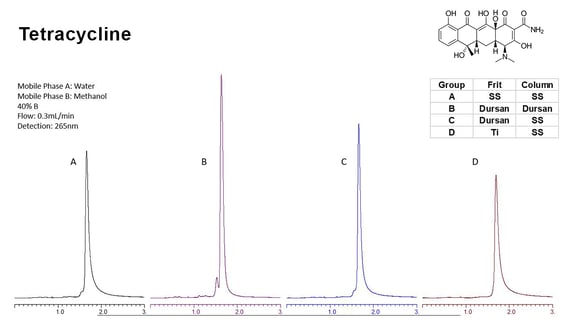

These chromatograms show Dursan-coated hardware outperforming stainless steel and titanium while measuring a tricky, chelating agent. In group B, the analysis is more sensitive and accurate while maintaining a faster response.

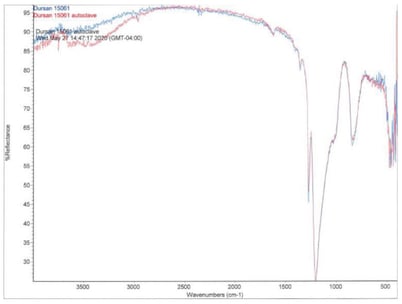

Enjoy Performance After Steam Sterilization

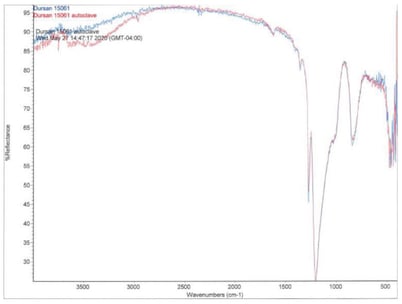

FTIR analysis shows there was little significant change observable before and after the autoclave exposure for the Dursan surface. A slight increase in Si-OH functional groups accounts for ~10° decrease in DI water contact angle.

Conclusion

SilcoTek's patented chemical vapor deposition process is designed to penetrate and coat complex geometries and small bore tubing. The non-line-of-sight deposition technology assures the inner bore of tubing is coated. This means that diagnostic systems can benefit from an inert, non stick, and corrosion resistant surface, improving the accuracy, repeatability, precision, and durability of test systems while reducing the risk of carryover and cross contamination.

To learn more about our coatings, subscribe to our blog, or follow us on LinkedIn. Our coating experts are here to solve your material science problem. Have a bio-inert coating question? Contact our Technical Service Team.

In this blog post we discuss how non reactive, high purity coatings like Dursan improve in vitro diagnostic probes and needles.

In this blog post we discuss how non reactive, high purity coatings like Dursan improve in vitro diagnostic probes and needles.