This week, we wanted to talk about how our 2 newest coatings, Siltride® 1000 and Silcolloy 2000®, can help with corrosion. In many industries, corrosion is a tremendous pain in the backside. It can be costly, time-consuming, and causes major headaches. When dealing with highly corrosive substances like hydrocloric acid (HCl) and sulfuric acid (H2SO4), it's hard to find an easy solution to this troublesome problem.

Corrosion costs the global economy more than $2 trillion every year (Hays). A significant portion of these costs come from critical industrial processes that are often hidden from the naked eye. Oil, gas, and chemical industries are known for investing heavily in corrosion protection due to the aggressive chemistries involved, but even high purity applications suffer from frequent equipment maintenance and replacement due to corrosion. Companies in these industries have an even greater challenge because typical corrosion coating solutions are incompatible with high purity processes and impossible to use. Manufacturers of semiconductors, pharmaceuticals, and fluid control components need special coatings and surface treatments that can be trusted to not contaminate and reduce yields.

This is exactly where SilcoTek steps in to help. This blog article features SilcoTek’s newest corrosion resistant coatings, Silcolloy 2000 and Siltride 1000, and how they drastically improve the lifetime and performance of the most common material of construction in industrial technology, 316L stainless steel. See how our new coatings compare below.

Coupons: Uncoated (left), Siltride 1000 (center), Silcolloy 2000 (right)

Increased Corrosion Protection

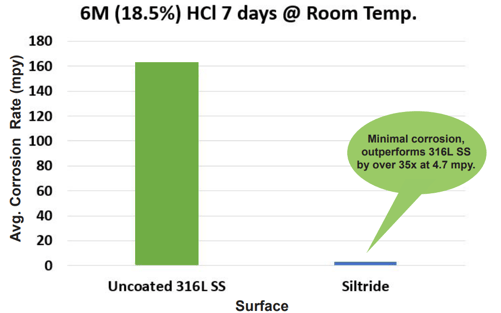

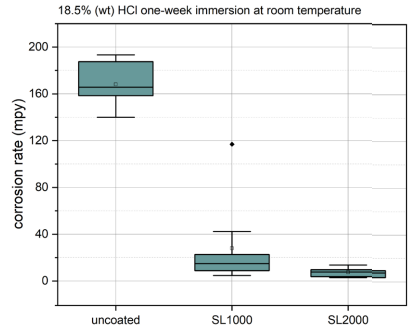

Our newest coatings, Siltride 1000 and Silcolloy 2000, shine as coatings for corrosion protection. The graphs below show how they outperform uncoated coupons when combatting HCl and H2SO4.

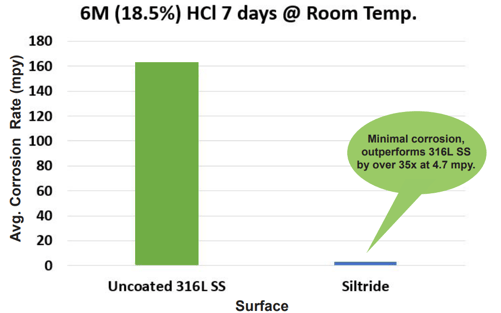

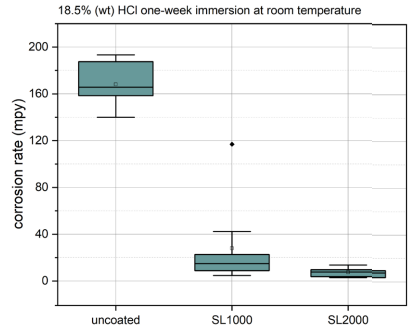

HCl - 7 days at room temperature

These tests shows an aggressive environment testing the limits of Siltride 1000 and Silcolloy 1000 & 2000. In these conditions, both Siltride 1000 and Silcolloy 2000 performed well with minimal corrosion while considerably outperforming uncoated 316L stainless steel. By utilizing SilcoTek's patented chemical vapor deposition (CVD) coatings, our customers can be reassured that their parts will stand up to corrosion.

Siltride 1000 vs. Uncoated Coupon

Silcolloy 1000 & 2000 vs. Uncoated Coupon

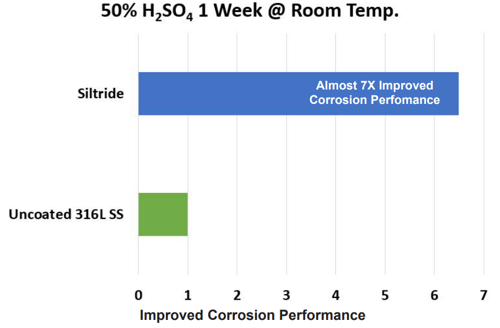

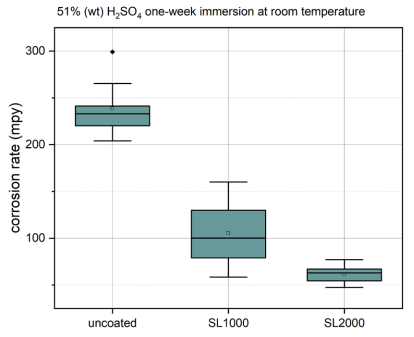

H2SO4 - 7 days at room temperature

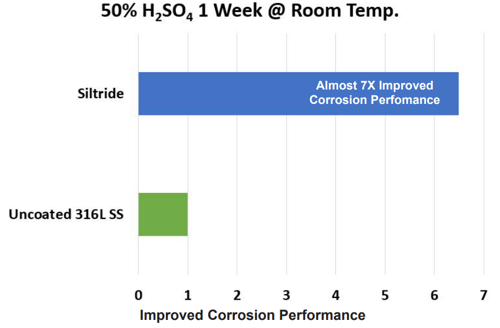

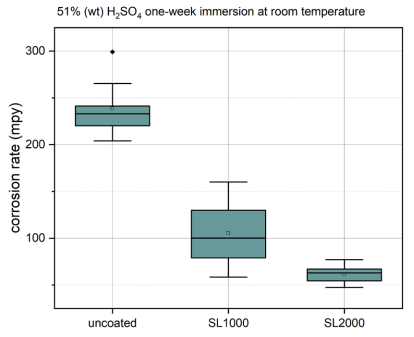

Similar to the HCl data, SilcoTek's coatings held up well to sulfuric acid. When measuring the average corrosion rate (mpy), Siltride 1000 showed a nearly 7x improvement over uncoated 316L stainless steel. Silcolloy 2000 held up even better than our original Silcolloy 1000.

Siltride 1000 vs. Uncoated Coupon

Silcolloy 1000 & 2000 vs. Uncoated Coupon

Industries Using Corrosion Resistant Coatings

We coat a variety of instruments for many different industries, including semiconductor, pharmaceutical, research, and complex chemistry that all battle corrosion. There are so many opportunities for SilcoTek's coatings to help in almost any field. Here are just a few examples:

Common Applications for SilcoTek Coatings

- Valves

- Heat exchanger coils

- Pumps

- Reactors

- Fittings and fasteners

- Gas transfer/delivery systems

- Downhole components

- Nozzles

- Tubing

- Process sampling equipment

What can we help you with?

Think your application could benefit from improved corrosion resistance? Contact our experts today!

Want more content from SilcoTek about our new applications and coatings? Subscribe to receive our updates!

Reference:

Hays, G. (n.d.). Now is the Time. https://corrosion.org/Corrosion+Resources/Publications/_/nowisthetime.pdf