Have you ever wondered why certain flavors taste or smell differently depending on the brand? SilcoTek has helped Givaudan, a world leader in creating many natural and artificial flavors. This CNN Health video is worth the 8:30 minute watch, but at 6:10 you will see SilcoTek's SilcoNert 2000 coated parts in action with this fragrance device. Dr. Sanjay Gupta interviews Givaudan senior flavorist Kim Juelg, who explains how this apparatus works.

SilcoTek's Dursan coating is NSF approved and FDA compliant. The process is designed to improve the inertness, durability, fouling and corrosion resistance of products ranging from precision instrumentation to severe industrial applications. The Dursan coating process bonds the coating to stainless steel, alloy, ceramic, and glass, making a high tolerance durable coating even under extreme temperatures and pressures. In doing so, it allows for a corrosion resistant surface, improved testing reliability and accuracy, and reduced replacement equipment costs. Our SilcoNert 2000 coating is also great for these applications. With superior inertness, you can expect better process control, improved reliability and accuracy, and less down time.

For this application, chemical analysis of the flavors would need to be extremely regulated. Here is an example of how our coated products can help to examine your samples down to the part-per-billion level.

Precise detection of trace compounds in fragrances or odorants require surfaces that minimize adsorption and contamination by the analyte flow path. Olfactory detection and analytical systems must clearly and consistently detect trace compounds in the part-per-billion range. In order to achieve reliable ultra low level detection, the flow path surface must allow all of the sample to reach the LC, GC or GC-MS detector.

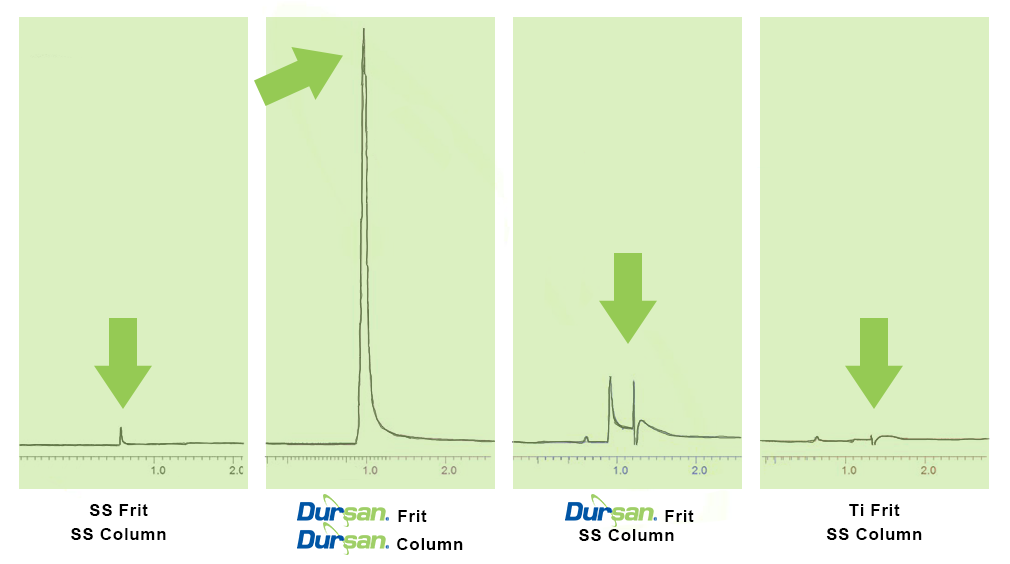

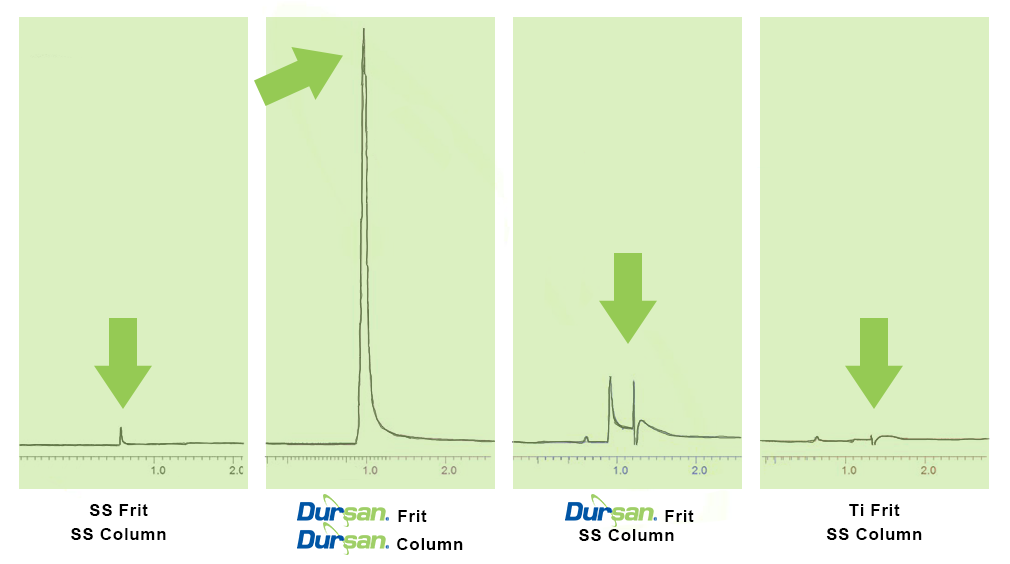

Comparing a prepared, known sample concentration in coated and uncoated HPLC systems:

The first chromatogram shows the result when testing with a stainless steel frit and stainless steel column in the flow path. There is very little signal response, indicating flow path adsorption and loss of sample. This makes precise trace detection of target compounds difficult.

The next chromatogram shows results using a Dursan® coated frit and column. The peak is much larger and shows minimum tailing or distortion. This indicates that all of the sample is reaching the column and detector without flow path adsorption, making consistent detection of trace compounds for fragrance analysis or odor detection possible.

The other chromatograms at the right show how the same sample peak can be distorted when even part of the flow path is reactive.

Trace VOC Detection:

Odor detection and fragrance analysis often relies on the sample system's ability to detect airborne volatile organic compounds (VOCs). Trace VOC analysis can be improved by using SilcoNert coated stainless steel.

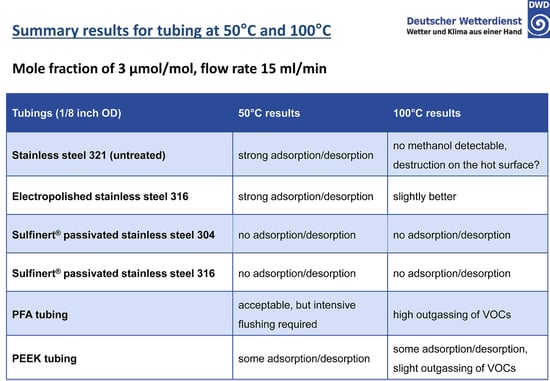

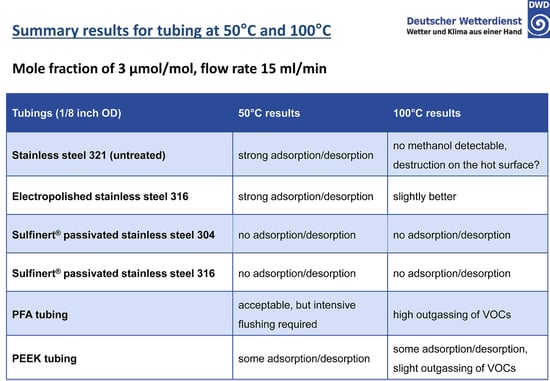

Testing by Mr. Stefan (S.T.) Persijn of VSL, Dutch Meteorological Society, (in conjunction with the German Meteorological Office, DWD) presented a comparative study of adsorptive properties of various materials commonly used in VOC analysis.

The study exposed various tube surfaces to methanol at 50 and 100°C and measured adsorption rate of the surfaces. Results show that an inert coating like SilcoNert® (called by the trade name Sulfinert® in the study) coated stainless steel prevented adsorption and reaction with VOCs in critical flow paths. The study summary below highlights the comparative results:

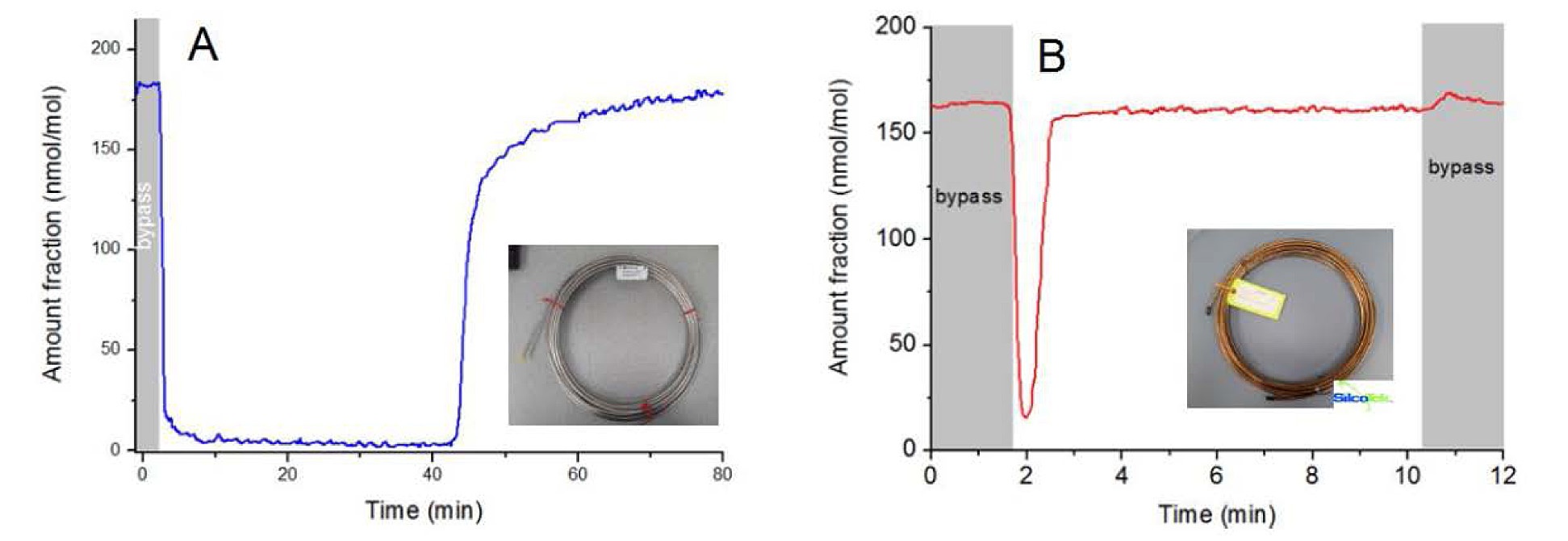

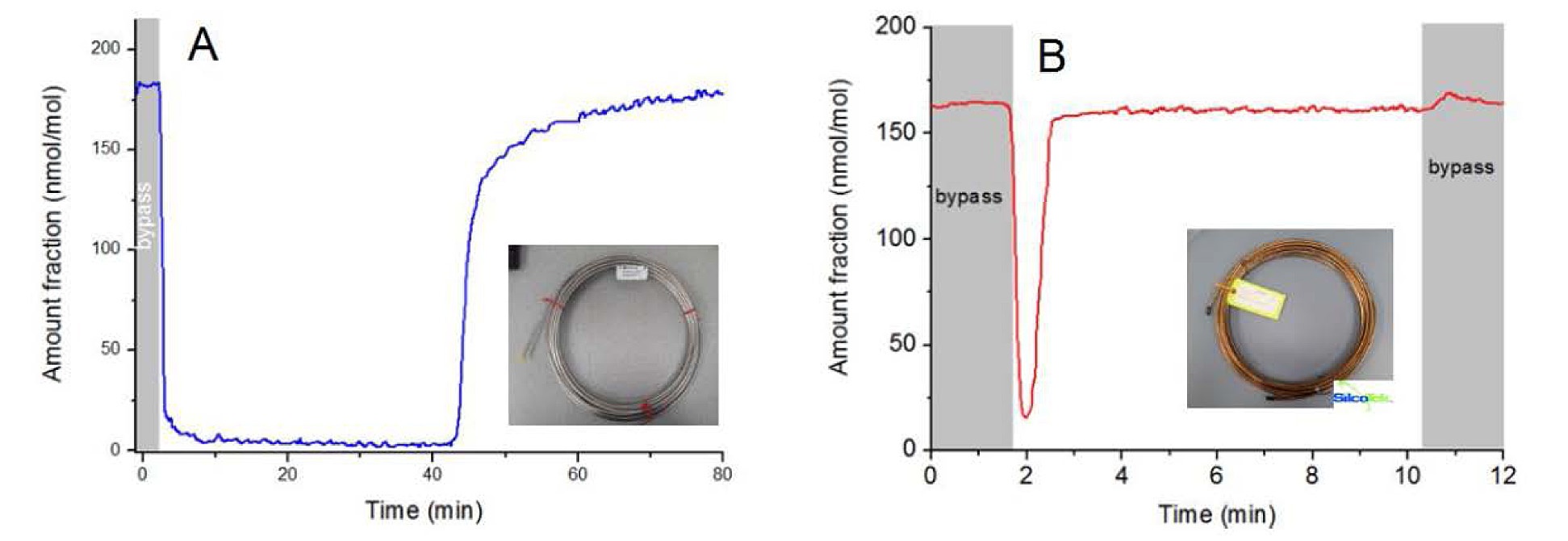

The VOC team then compared 10 meter lengths of SilcoNert 2000 coated and uncoated stainless steel tubing (below). The team passed a 180 umol/mol methanol mixture through a bypass (grey areas), then switched to the test tubing. They measured the time to achieve baseline concentration for each tube. The SilcoNert coated tube took less than a minute to stabilize (graph B) compared to over 40 minutes for the stainless steel tube (graph A). The comparison demonstrates the severe adsorption of trace methanol on stainless steel flow path surfaces and highlights potential delays in response that can lead to significant data reliability issues when conducting trace VOC analysis.

The benefits of SilcoTek coatings in Food, Flavors, and Fragrances applications include:

- Improve response and quality of fragrance analysis

- Reduce protein binding and carryover of proteins

- Protect against cross-contamination, bacteria, and pathogens like Listeria

- Increase system lifetime and productivity

- Improve corrosion resistance, reduce metal impurities and contamination

- Apply to legacy equipment for immediate benefit

- Apply to hard to access parts and high risk contamination parts for added protection

SilcoTek coatings protect and improve:

- Food Processing Components

- Quality Assurance Testing Flow Path Components

- Fragrance Analysis and GC Components

- Protein Analysis and HPLC Components

- Stainless Steel Filters, Tubing, Fittings, Pumps, and more

Want to know more about our coating properties?

Contact us today for a free consultation with our coating experts!