Unlocking the full potential of Chemical Vapor Deposition (CVD) requires a comprehensive understanding of its intricacies and nuances. In this blog post, we'll explore the inner workings of CVD, its unique characteristics, benefits, limitations, and advanced strategies for optimizing the coating process.

Understanding the CVD Process

CVD involves a sophisticated interaction of chemical reactions and surface interactions to deposit thin films onto substrates. A precursor gas is introduced into a reaction chamber maintained at elevated temperatures and controlled conditions. Upon heating, the precursor decomposes or reacts, forming the desired coating material, which then adheres to the substrate surface. This process occurs across all exposed surfaces, ensuring a controlled coating thickness range and complete coverage.

Watch the SilcoTek coating process video below.

Characteristics and Advantages of CVD Coatings

CVD coatings exhibit several unique characteristics that set them apart:

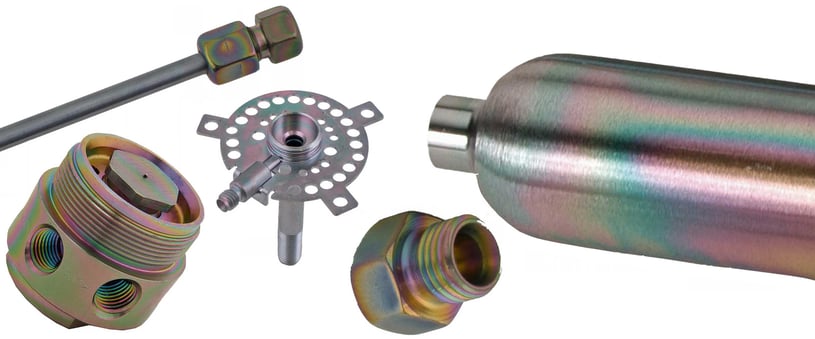

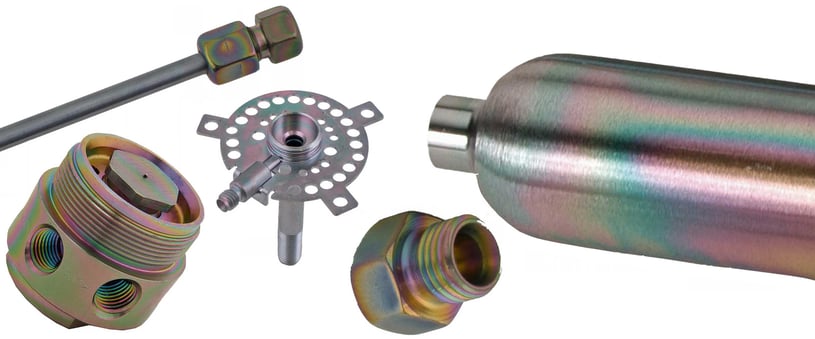

- Precision and Uniformity: SilcoTek's CVD processes offer exceptional control over coating thickness and full coverage, even on complex geometries and internal surfaces.

Coated frit section showing variance in thickness throughout the substrate.

- Durability and Stability: These coatings withstand extreme temperatures, corrosive environments, and mechanical stress, providing long-lasting protection to a wide variety of substrates.

- Tailored Properties: CVD allows for the customization of coating properties to meet specific application requirements, such as chemical inertness, wear resistance, or system purity. Contact our experts for more information on how we can tailor a coating for your exact needs.

- Versatility and Compatibility: Compatible with a wide range of substrates, including metals, ceramics, glass, and metal alloys, CVD coatings find applications across diverse industries.

Challenges and Limitations of CVD

Despite its numerous advantages, CVD poses certain challenges and limitations:

- High Temperature Requirements: Some precursor materials require elevated temperatures for efficient deposition, limiting compatibility with heat-sensitive substrates. Check out our material compatibiliy guide for many of the substrates we commonly coat.

- Size and Scale Constraints: Chamber capacity imposes limitations on the size and quantity of parts that can be coated simultaneously, necessitating batch processing and potentially increasing lead times. For example, below are the maximum coiled tubing lengths to achieve an optimal coating.

.jpg?width=471&height=524&name=Max%20coil%20length%20table%20(003).jpg)

Advanced Strategies for Maximizing CVD Benefits

To overcome these challenges and find maximum value from CVD coatings, consider implementing advanced strategies:

- Advanced Fixture Design: Collaborate with SilcoTek's experts to develop custom fixtures and tooling to ensure precise part positioning, uniform coating distribution, and minimized process variations.

- Substrate Selection: Check out our material compatibility guide to see which substrates our coating works best with.

- Chemical Compatibility: See also our chemical compatibility guide to check which coating would work best for your application.

- Provide Application Details: Allow our dedicated scientists to study your specific application to determine the best coating for you.

- Proactive Information: Inform our team of any critical surfaces or special instructions for processing beforehand so we can take that into consideration when determining how best to process your parts.

- Collaborative Development: Partner with experienced CVD coating providers and materials scientists to leverage our expertise in precursor selection, process optimization, and coating characterization.

- Utilize Quantity Break Pricing: Sending larger quantities of parts allows you to take advantage of our quantity break pricing.

Conclusion

Chemical Vapor Deposition offers a plethora of capabilities for coating applications, delivering precision, durability, and versatility across many industries. By understanding its principles, addressing challenges, and implementing advanced strategies, we can maximize the benefits of CVD coatings, enhancing product performance and reliability of your products in diverse applications.

Want to know more about the coating process and how we can help you? Contact our coating experts today for your FREE coating quote!

.jpg?width=471&height=524&name=Max%20coil%20length%20table%20(003).jpg)