Hydrophobicity is defined as, "lacking affinity for water." For many applications, hydrophobicity is essential for proper fuctioning. SilcoTek specializes in applying advanced coatings using chemical vapor deposition (CVD) technology. While our coatings encompass a range of functionalities, we have formulations that contribute to hydrophobicity. At the core of SilcoTek's hydrophobic coatings lies a science that alters surface properties at a molecular level. These coatings boast low surface energy, causing water droplets to bead up and roll off rather than adhere, resulting in surfaces that stay dry and resistant to water-related damage. Moisture can have deleterius effects on process analytical systems, leading to inaccurate or false results. Moisture also accelerates corrosion, especially in assembly points where water can become trapped. Other sticking problems with chemicals, plastic, carbon coking in high temperature environments, biological samples, and more can be solved with hydrophobic surface coatings.

Here's how SilcoTek coatings aid in enhancing hydrophobic properties:

Surface Modification:

- Material Transformation: SilcoTek's coatings modify the surface properties of substrates, typically metal or glass, creating a chemically altered surface that resists water absorption.

- Functional Group Integration: By introducing specific functional groups during the CVD process, the surface becomes inherently hydrophobic, repelling water droplets upon contact.

Properties of SilcoTek Coatings:

- Low Surface Energy: The coatings have a low surface energy, causing water droplets to bead up and roll off the surface rather than spreading out and adhering to it.

- Uniform Coating Thickness: SilcoTek's precise coating application ensures uniform thickness across surfaces, optimizing hydrophobic performance.

Benefits for Hydrophobicity:

- Durability: Our coatings are highly durable, maintaining their hydrophobic properties over extended periods, even under harsh conditions.

- Chemical Resistance: These coatings exhibit resistance to chemicals and corrosion, crucial for applications where exposure to harsh environments might otherwise compromise hydrophobicity.

Customization for Specific Applications:

- Tailored Solutions: We provide customizable coatings, allowing adjustments in chemistry to meet the specific needs of diverse industries and applications requiring varying degrees of hydrophobicity. Work with our knowledgeable experts to determine if we have a solution that fits your needs.

Advantages in Various Industries:

- Medical Diagnostics, Pharmaceuticals, & Healthcare: Enhanced biocompatibility and reduced contamination risks in medical equipment as well as ensuring accurate results and equipment uptime by preventing surface activity.

- Automotive Industry & Aerospace: Improve fuel efficiency by preventing carbon coking on fuel injectors, sensors, exhaust paths, oil transfer lines, and more.

- Power: Increase performance by preventing scaling and fouling on heat exchanger surfaces.

- Mold Release, Packaging, and Plastics: Increase plant uptime by reducing maintenance.

- Semiconductor: Ensuring moisture is quickly and entirely removed from ultra-high vacuum systems.

- Analytical Chemistry: Repel water, resulting in faster purging/removal in sample transfer and analytical systems to eliminate water related adsorption and corrosion.

By leveraging our expertise in surface modification and precision coating application, SilcoTek offers tailored solutions that effectively enhance hydrophobicity, providing numerous advantages across industries where water repellency is crucial.

Our Coatings in Action

High Temperature Capability

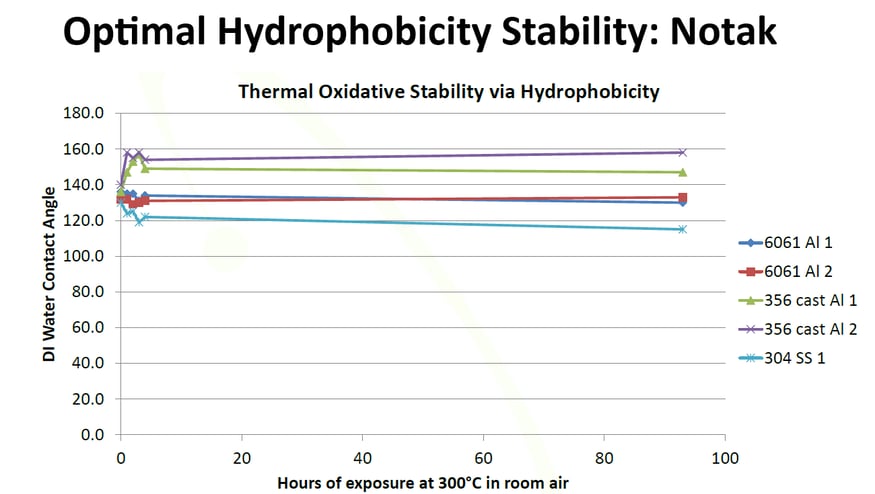

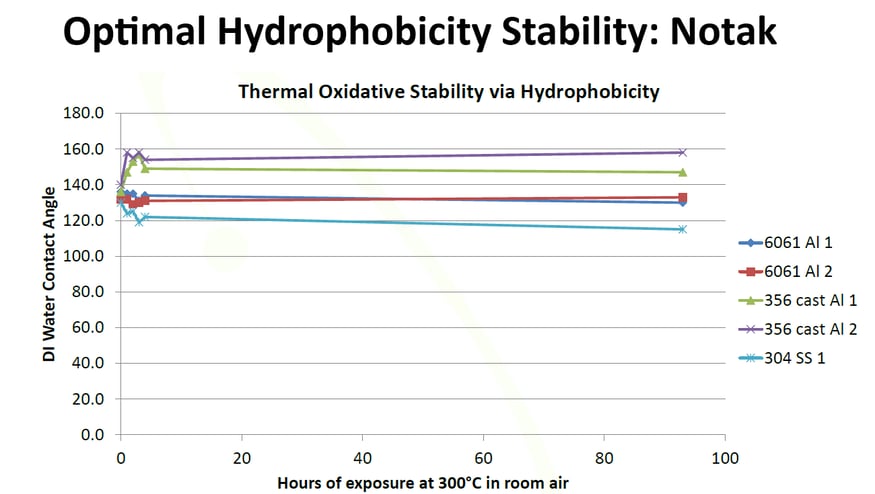

Given the nature of analytical systems refining or cleaning for that matter, we can expect the surface to be exposed to elevated temperatures. PTFE is high temperature limited and can fail in many high temperature applications. We exposed the Notak surface to an elevated temperature (300°C) for several hours to gauge the impact to wettability and contact angle on various surfaces. The graph below shows consistent contact angle readings over the 90+ hour test. PTFE would have failed at 250°C.

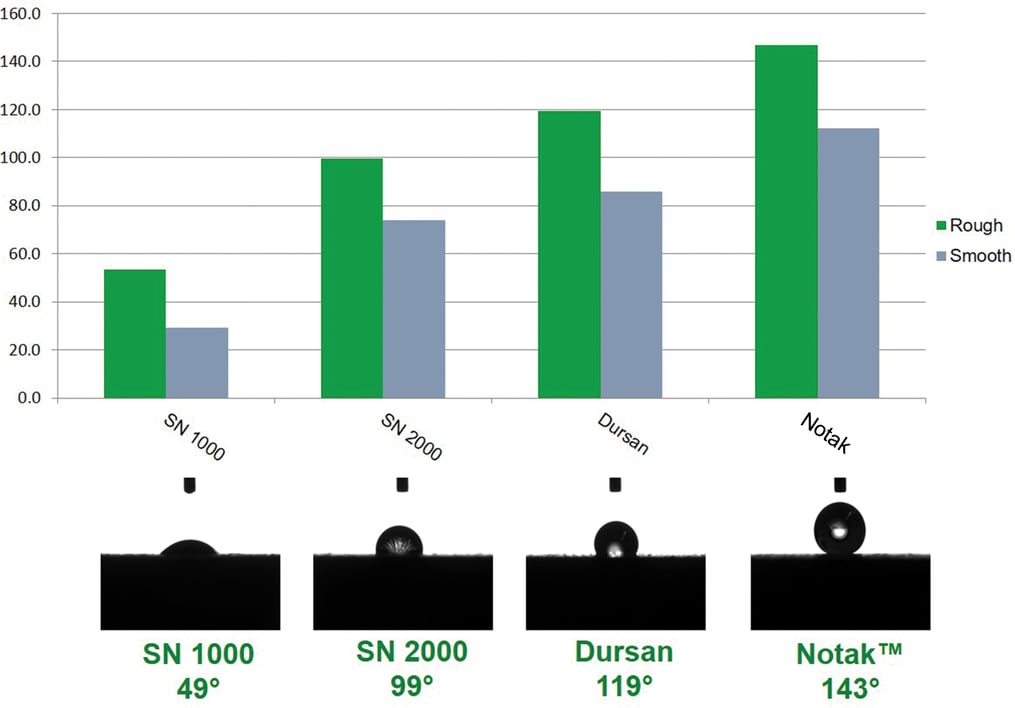

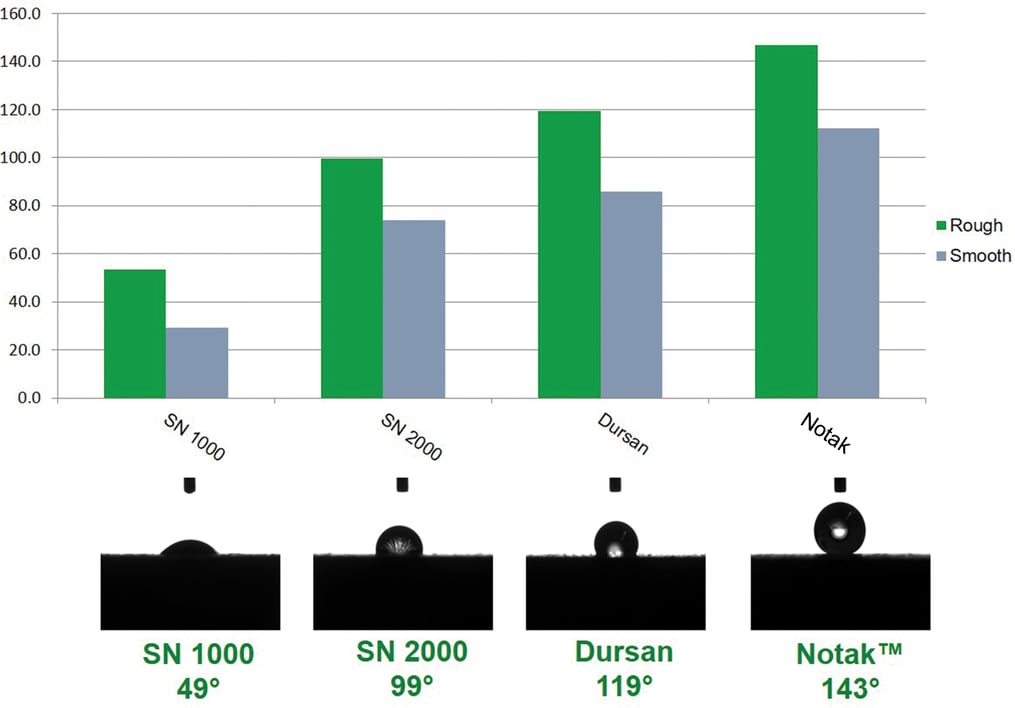

The comparative graph below highlights the water repelling properties of our coatings when compared to stainless steel. As presented below, SilcoTek's SilcoNert 1000, SilcoNert 2000, Dursan, and Notak all vastly outperform bare stainless steel when it comes to hydrophobicity. Let's talk about how our coatings can benefit you.

* Above contact angle measurements taken on rough coupon surfaces.

The best part about SilcoTek coatings? They can be applied to your components without costly re-engineering or significant change to dimensional tolerance. SilcoTek coatings offer a durable high-tolerance alternative to costly super alloys or polymeric coatings. Our coatings can be applied to complex flow paths without changing part functionality.

To improve hydrophobicity in analytical systems, coat the entire flow path. Don't forget to coat the purge gas system and calibration flow path! Here are some common items we typically coat:

- Regulators

- Fittings

- Valves

- Tubing

- Filters

- Analytical components

- Probes

- Moisture sensors

Coating Benefits Include:

- Less water accumulation and retention in analytical systems

- Faster system purge. Water is repelled so it’s easily removed

- Fast recovery. Fast-drying surface allows for quicker response

- Improved fouling resistance. Less maintenance of plant systems

The benefits of a hydrophobic coating don't end there, though! Contact us to find out how our coating properties can make your applications easier, cheaper, faster, and more reliable.

Want to keep up with the latest news from SilcoTek? Subscribe to our communications!