A team member was contacted by an individual wondering if we offer coatings with icephobic properties. Read on to learn what we discovered.

Coatings that are Ice Repelling and Icephobic

A few weeks ago a customer called to ask if any of our surfaces had ice repelling or icephobic or surfaces with weak ice adhesion properties. Although we do not have specific instrumentation to quantitatively test this property, we were able to devise a simple qualitative proof of concept test.

|

In this blog post you will learn:

- How to devise a simple test to determine if a surface is ice repelling, icephobic.

- Learn which coating has the lowest ice adhesion.

- Get a CVD coating information and comparative data about hydrophobic and icephobic coatings.

- Get resource tips on how to stop fouling and sticking.

|

About Icephobic Surfaces

Like water repelling surfaces, icephobic surfaces can repel ice or stop the formation of ice. The ice repelling property can be attributed to the structure of the surface or low surface energy which results in low adhesion and easy removal of ice.

Low energy surfaces that prevent ice adhesion may provide substantial benefits for applications utilizing heat exchangers, as well as applications that are negatively affected by the accumulation of ice, such as aircraft or instrumentation components. SilcoTek® works with customers to solve adhesion problems. Our Dursan® and Notak® coating technologies lower surface energy, increase hydrophobicity and water repelling properties. Read our surface adhesion case study.

Evaluating surfaces using commercially available instrumentation is feasible but can be expensive, especially when initially screening surfaces for icephobicity. Although we do not have specific instrumentation to quantitatively test this property, we were able to devise a simple qualitative proof of concept test.

Testing the Surface

Using a standard food storage freezer (at 0°F / -18°C), a variety of SilcoTek® surfaces were placed in the freezer and 1-2ml of DI water dropped added to the middle of each room-temperature coupon. The coupons were enclosed within the freezer overnight. The next morning, a metal pick was used to laterally remove each ice ball from the coupon surfaces. The degree of removal difficulty was subjectively rated on a scale of 1-10 (1 = easy, 10 = difficult) with accompanying observations.

Notak® has a low surface energy of approximately 10.5 mN/m compared to an untreated 316 SS surface of approximately 45.8 mN/m. This low surface energy may allow ice to release from a Notak surface with little effort. Additional SilcoTek surfaces will be evaluated for comparative analysis.

SilcoTek's Technical Service and Research and Development Team are here to advise and help customers select and test coatings that best fit your application. Contact our team to discuss your application it's free!

Data and Discussion:

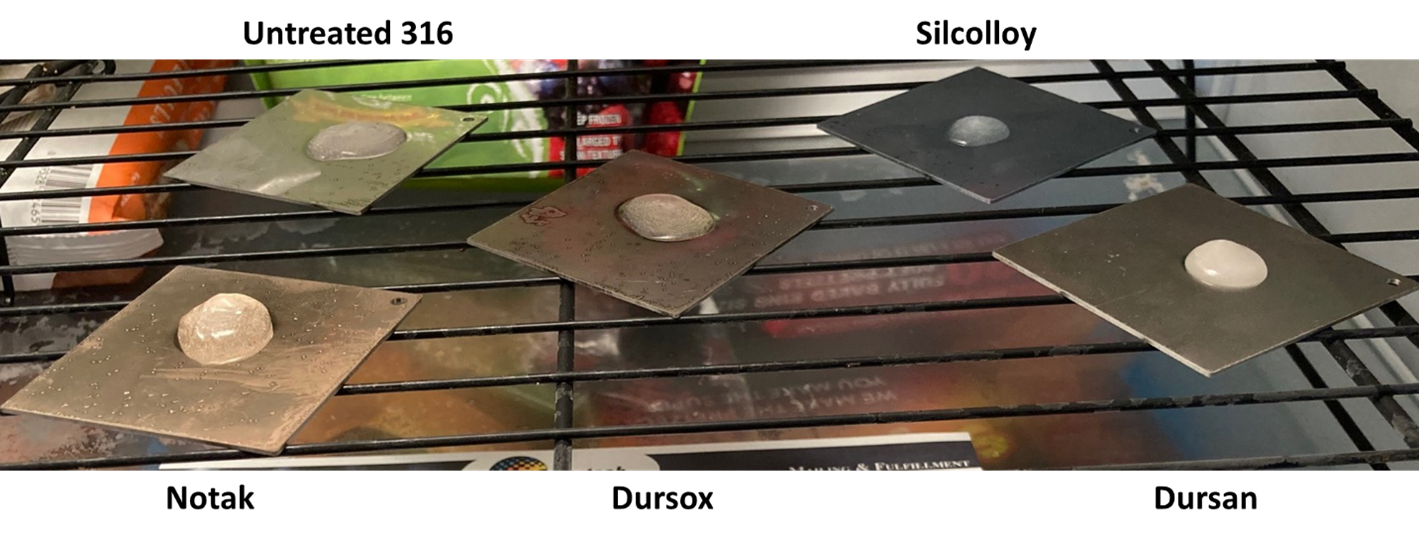

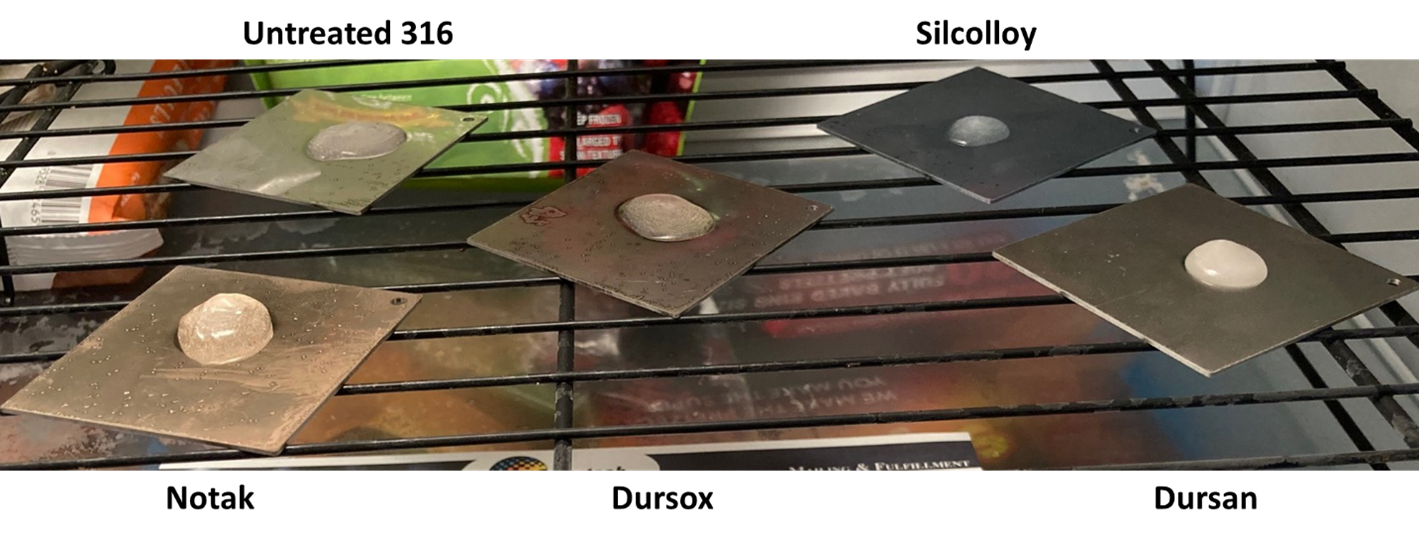

Coupons of various SilcoTek surfaces (and an uncoated control) were placed on a rack within a commercial freezer at 0°F / -18°C. Upon placement, approximately 1-2ml of DI water was dropped on to the center of a coupon. The coupons resided in the freezer with the door closed for 16 hours.

Upon opening the freezer door (see photo), each coupon was individually removed and rapidly tested to avoid the potential impact of thawing. A metal pick inserted at the point of ice attachment to the coupon was used to laterally remove the ice. The effort required (1 = easy, 10 = difficult) to remove the ice and associated observations are listed in the table below.

|

316 SS Coupon Surface

|

Effort (1-10)

|

Observations

|

|

Notak

|

2

|

complete removal with little effort

|

|

Dursan

|

6

|

partial removal from surface with effort

|

|

Silcolloy 1000

|

7

|

partial removal from surface with greater effort

|

|

Dursox

|

8

|

difficult, bulk chipped with minimal surface separation

|

|

Uncoated

|

8

|

difficult, bulk chipped with minimal surface separation

|

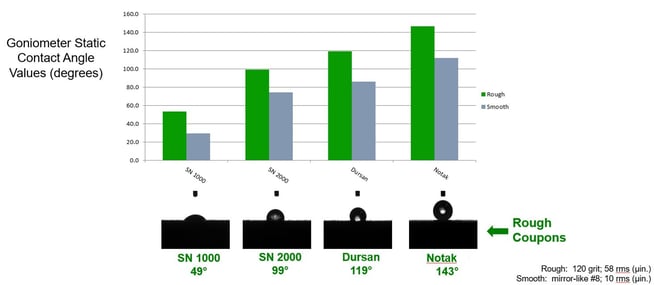

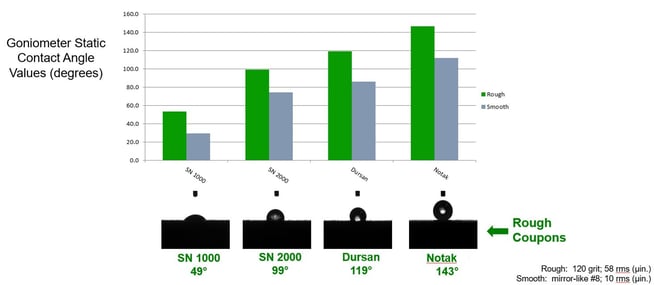

How do I get a surface to match my desired moisture level of moisture resistance?

You don't have to make a super radical change to material or product construction in order to change the moisture performance. Fortunately we offer silicon barrier coatings with a wide range of water management capabilities.

Want a more corrosion resistant or inert coating with a low surface contact angle? Try SilcoNert® 1000 or Silcolloy®. If you're looking for an inert coating that's not too moisture repelling, go with SilcoNert® 2000. Need a hydrophobic coating or superhydrophobic coating? Dursan® or our new Notak surface may do the trick. Have a fouling problem? Learn more about solving fouling problems.

Note, our Notak coating is in pre-production Beta testing so we have limited capacity for that coating. Contact our Technical Service Team to discuss your application and we'll be happy to make a coating recommendation.

Conclusion:

Only Notak® displayed significant icephobic properties where the frozen droplet completely removed from the Notak coupon surface with relative ease, giving a rating of 2 (good).

The subjective data indicates an opportunity for the application of Notak surfaces for the prevention of ice accumulation and provide opportunities for ice release with little effort from surface.

Have a question about icephobic or hydrophobic surfaces? Our Technical Team can help you select the best coating for your application or can advise you on the best way to evaluate our coatings. Join us on LinkedIn to learn more.