by Dr. Min Yuan

Recently there has been an increasing amount of inquiries from existing and potential customers on the electrical properties of SilcoTek coatings. Different customers require different electrical properties depending on their specific applications. Although our coatings are in general poor electrical conductors, we had not performed any systematic study to quantify the electrical properties in our coatings. Therefore to gain a better understanding of our coatings’ electrical properties will not only help us provide better advice to our customers.

The method used for study is the polarization vs. field measurement (P-E loops). This is done under low applied voltages and it serves as a quick screening method to check whether a coating’s response to applied electric field is “capacitor-like” or “resistor-like”. Study 2) and 3) are performed with a Cascade probe station and high voltage breakdown measurement tool, equipped with a temperature-controlled bath.

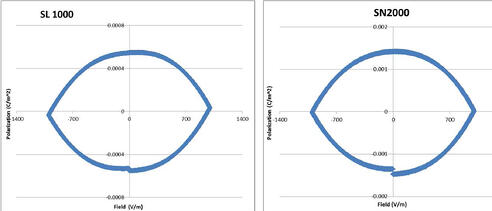

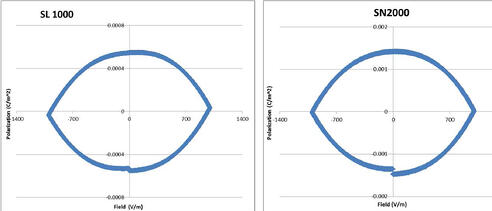

Two of our silicon-based coatings (Silcolloy and SilcoNert 2000) were characterized and their P-E responses are shown below in figures 2a and 2b, respectively. These measurements indicate that our silicon-based coatings exhibit large resistive leakage and are more “resistor-like” than “capacitor-like”. This may be expected as silicon is a semiconductor and known to be a lossy material. Learn more about SilcoNert and Silcolloy.

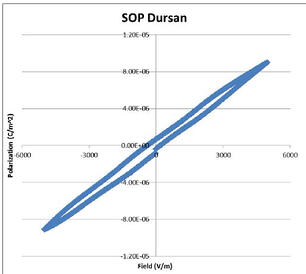

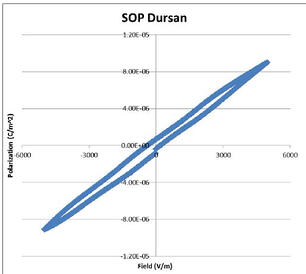

The P-E response of SOP Dursan coating is shown in figure 3, and it represents what’s described as a “lossy capacitor”. Compared to figures 2a and 2b, the loop is much narrower, indicating resistive leakage at a much reduced level. The area within the P-E loop is proportional to the loss tangent of the device, and the slope proportional to the capacitance. The improvement on the loss factor of Dursan compared to silicon-based coatings is due to the oxidized nature of Dursan. Silicon dioxide (SiO2) is a good dielectric material with low loss and high breakdown strength on the order of 10MV/cm.4,5 Dursan, however, contains carbon and is not a fully-oxidized SiO2 film

Learn more about Dursan.