In many industries, valves are mission-critical components. They control fluid flow, regulate pressure, and maintain system integrity. But in harsh process environments - whether that’s semiconductor gas delivery lines, analytical chemistry sampling systems, pharmaceutical manufacturing, or energy production - unprotected valves can quickly become a source of problems.

Corrosion, contamination, and wear not only shorten valve service life, they also risk product purity and process accuracy. That’s why more engineers and maintenance managers are choosing valve corrosion protection and inert coatings for valves as a proactive solution.

Why Use CVD Coatings on Valves?

SilcoTek specializes in chemical vapor deposition coatings (CVD) that molecularly bond to stainless steel and other alloys. Our proprietary coatings are designed to solve the most common valve performance issues:

Corrosion Resistance: In offshore energy platforms, chemical plants, and process lines exposed to acids or chlorides, corrosion is inevitable without proper protection. Dursan®-coated ball valves have shown over 10× better corrosion resistance than bare stainless steel in ASTM B117 salt spray testing, extending maintenance intervals and reducing downtime.

Inert, Non-Reactive Flow Paths: For semiconductor manufacturing and analytical applications, even microscopic surface activity can alter results. SilcoNert® coatings create an ultra-inert surface inside the valve, preventing adsorption of sulfur, mercury, ammonia, VOCs, and PFAS compounds. This ensures accurate readings from parts-per-billion down to parts-per-trillion concentrations.

Improved Wear Resistance: Valves in high-cycle or abrasive environments benefit from harder, smoother internal surfaces. Our coatings reduce galling, improve seal performance, and resist particle shedding - critical for maintaining purity and protecting downstream equipment.

There are so many different types of valves - all with different componentry. Some commonly coated valve components are:

- Balls

- Stems and needles

- Poppets

- Springs

- Actuators

- Seats, washers, retainers, and glands

- Diaphragms

- Bonnets

- Plugs

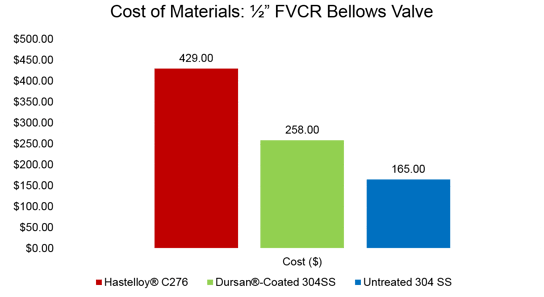

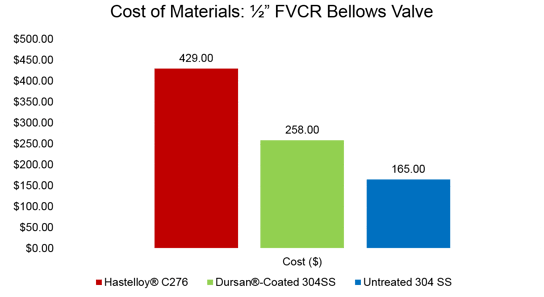

Cost comparison: Exotic alloys like Hastelloy can be costly, but coated valves provide superior protection without the added expense.

Proven Benefits in Real-World Applications

One major petrochemical facility replaced uncoated valves in its sampling lines with SilcoNert-coated versions. The result: maintenance intervals extended from six months to three years, significant cost savings, and safety improved due to fewer leak-related interventions. Read the study HERE.

Similar results have been seen in semiconductor fabs, analytical labs, and pharmaceutical plants - anywhere CVD-coated valves are deployed to resist corrosion, maintain chemical inertness, and perform reliably over years of service.

SilcoNert-coated valves on both ends of this sample cylinder in the sampling system.

Why SilcoTek Coatings Work

Unlike spray or dip coatings, SilcoTek’s CVD process creates a uniform, pinhole-free layer that bonds at the molecular level. This means it will not chip, flake, or peel, even on intricate internal geometries. Because it adds virtually no thickness, it preserves valve tolerances, making it ideal for precision valve components.

If your valves are failing prematurely, contaminating your process, or costing too much to maintain, CVD coatings for valves can be the long-term solution you need. Contact SilcoTek’s technical team to discuss compatibility, performance data, and coating options for your application.

Handling Actuation

Some customers worry that the coating will wear or flake while in use. Our thin-film coatings actually performed better than bare stainless steel. The below table shows the results of a pin-on-disc test between Dursan and bare stainless steel. As shown, the wear rate was more than 2x that of the coated metal, so no flaking here! Speaking of flaking, SilcoTek coatings are not painted or baked on so they don't rely on adhesion to stay on the surface. Our CVD process diffuses the coating into metal, glass or ceramic surfaces. Our patented CVD process makes our coatings incredibly durable and securely bonded to the part surface.

Tips for Sending Valves for Coating

A quick note for sending valves in for coating: Please fully dismantle all assemblies and remove seals from internal cavities. Pressed-in and other seals are made of materials that are incompatible with SilcoTek's CVD process. To avoid risk of damage, all multi-piece assemblies will be returned uncoated.

Want to buy your valve assemblies straight from the source? Check out our list of approved partners, many of which stock already coated parts!

Have questions about getting your valves coated? Please reach out to our team!