|

|

Improve Corrosion Resistance and System Purity With New Dursan®

|

Next generation semiconductor technology will cost an estimated $10 billion per wafer fab facility. Maximizing yields and process efficiency will be even more essential to not only optimizing profit but ensuring the health of the company. Factors to consider when optimizing process yield and efficiency:

- Eliminate all sources of contamination

- Minimize start-up/burn-in of process equipment

- Extend equipment service life

SilcoTek's new semicon modified Dursan® coating improves new fab facility performance 4 ways:

- High purity silicon coating eliminates metal ion contamination

- Patented high durability coating technology improves wear resistance

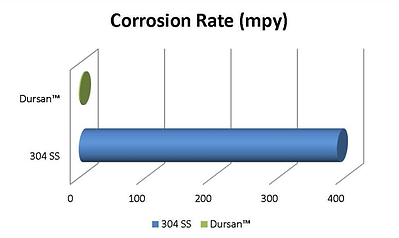

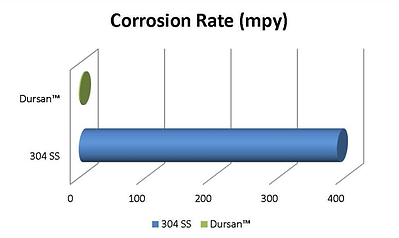

- CVD coating technology improves corrosion resistance; even in the smallest crevices or holes

- Inert Dursan coating eliminates the need for surface conditioning or burn-in

Semicon Modified Dursan® significantly improves corrosion resistance.

Turn Stainless Steel Into Silicon

Dursan's unique non line-of-sight CVD coating technology is ideal for coating complex geometries commonly found in semiconductor fab equipment. Dursan bonds to stainless steel, essentially making the stainless steel surface high purity silicon. Dursan allows the manufacturer the flexibility and ease of manufacturing components in stainless steel while benefiting from the inertness, purity, corrosion resistance and wear resistance of silicon.

Coat the entire flow path to maximize yield:

- Regulators

- Metal filters

- Tubing

- Manifolds

- Supply lines

- Showerheads

- Bubblers

Learn more!