We put our new Dursox® metal free coating to the test. Here's what happened.

We put our new Dursox® metal free coating to the test. Here's what happened.

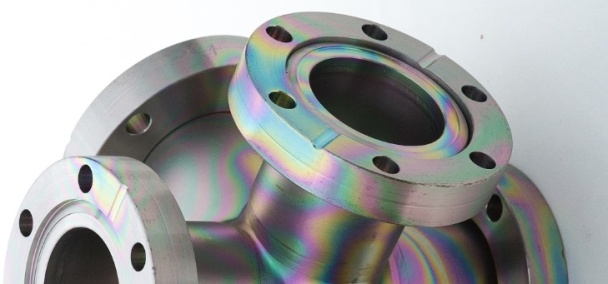

There are lots of corrosion resistant coatings out there. But what if you're concerned about metal contamination and metal leaching? Or what if you need to protect a precision instrument or flow path that requires high tolerance or high heat resistance and a dry coating technology? Then your options are limited. Want a metal free high durability corrosion resistant coating? Let's test our new Dursox coating and find out if it fits the bill.

|

In this blog post you will learn:

- Elemental composition of Dursox CVD coating

- How Dursox improves corrosion resistance by 80%

- Discover how Dursox prevents metal ion contamination & improves product quality

- Applications for a metal free coating & specifications

|

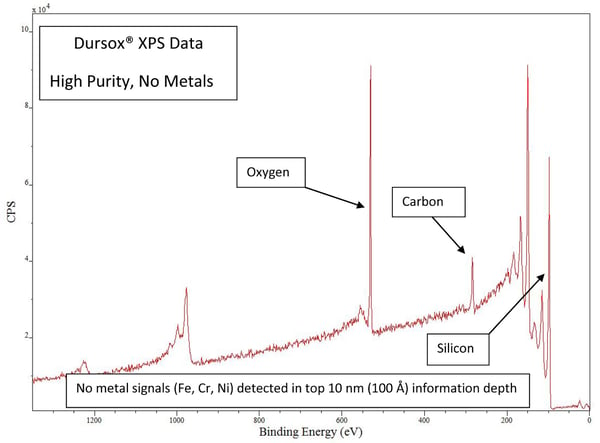

Is Dursox® metal free?

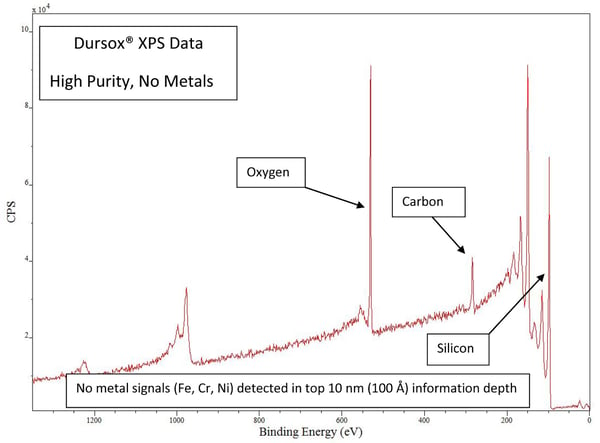

We measured the elemental composition of of Dursox to find out if it is in fact metal free. We tested the surface by X-ray Photoelectron Spectroscopy (XPS). Basically we blasted the surface with X-ray energy beams and analyzed the material that came off the surface. As the X-ray beam penetrates the surface you get a pretty good idea of what's in the material. The XPS plot below shows the coating consists of oxygen carbon and silicon, no metals. The amorphous structure of the material allows the coating to flex with the base metal without cracking or failing. That enables the coating to be used in high stress applications like high pressure cylinders or compression seal fittings.

No metal, check. But is it corrosion resistant?

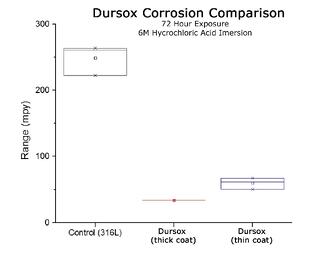

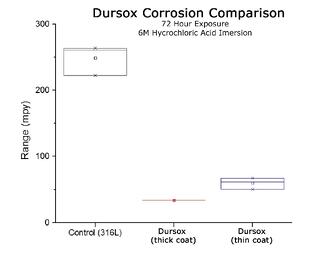

Let's look at the data. ASTM G31 hydrochloric acid immersion testing demonstrates the high purity corrosion resistance of Dursox®. After 72 hours the coated test sample showed roughly an 80% reduction in corrosion compared to uncoated 316L stainless steel.

Dramatically less corrosion, but what about ion contamination? Let's do a visual check and find out.

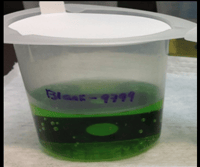

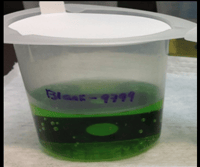

Here's a photo of the uncoated coupon during the HCl immersion test. Notice the green liquid? HCl is clear so why is this beaker green? That's the result of chloride corrosion of the stainless surface and metals being leached from the coupon. A great example of metal ion contamination.

Here's a photo of the uncoated coupon during the HCl immersion test. Notice the green liquid? HCl is clear so why is this beaker green? That's the result of chloride corrosion of the stainless surface and metals being leached from the coupon. A great example of metal ion contamination.

Applications that require high purity, are sensitive to contamination (like semiconductor fabs), analytical testing, or processes where metals can impact yield, this sort of contamination can cost a company in high maintenance, poor product quality or low yields.

The Dursox® HCl beaker by comparison is clear. There's no change in color so no leaching of nickel into the acid solution. The result? More accurate test results, improved flow path durability, lower maintenance and better product quality.

The Dursox® HCl beaker by comparison is clear. There's no change in color so no leaching of nickel into the acid solution. The result? More accurate test results, improved flow path durability, lower maintenance and better product quality.

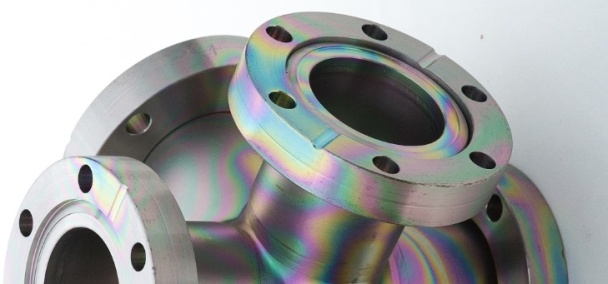

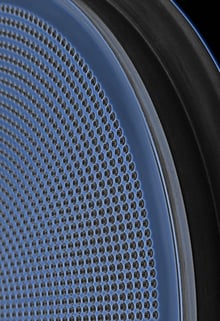

Benefits

Dursox® makes critical surfaces non reactive and corrosion resistant, preventing process contamination and improving yield. The highly inert CVD coating offers improved stability, delamination resistance and durability over ceramic coatings like yttria. The coating is ideal for high purity gas transfer flow paths, high purity applications where corrosion is a concern, and whenever improved durability for precision instrumentation is needed.

|

| Etch |

High purity coating eliminates ion contamination in corrosive etch gas streams. |

| Atomic Layer Deposition (ALD) |

Enhance purity by coating of all chambers and equipment. Reduces carryover, burn-in, and corrosion. |

| Ozone |

Stabilize flow path to assure ozone purity. |

| Gas Transfer |

Prevent ion contamination, assure high purity gases. |

| Chemical-Mechanical Planarization (CMP) |

Increase lubricity, prevent sticking and cut downtime. |

| Epitaxy |

Significantly reduces contamination and maintenance caused by corrosion. |

|

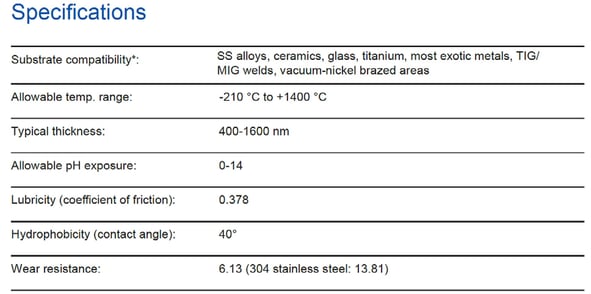

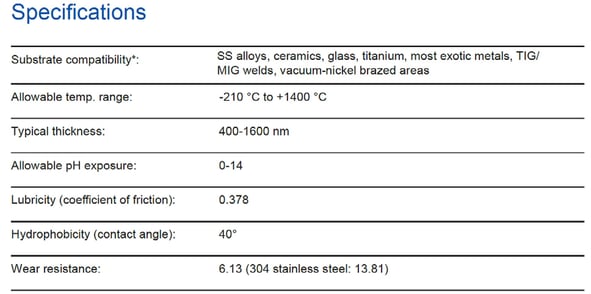

Dursox® Specifications

Need a dry coating that will withstand exposure to extreme temperatures or challenging process environment? Dursox specifications highlight the durability and heat resistance of the coating. Our CVD coating technology is moisture free and deposits a thin high tolerance silicon coating onto the surface of metal, glass, and ceramics. Contact our Technical Service Team to discuss your application or to arrange an evaluation with our R&D staff.

Not sure if Dursox® fits your application? We've got coatings for a variety of corrosion resistant applications. Read our corrosion presentation and get relevant data to improve your process.

We put our new Dursox® metal free coating to the test. Here's what happened.

We put our new Dursox® metal free coating to the test. Here's what happened.

Here's a photo of the uncoated coupon during the HCl immersion test. Notice the green liquid? HCl is clear so why is this beaker green? That's the result of chloride corrosion of the stainless surface and metals being leached from the coupon. A great example of metal ion contamination.

Here's a photo of the uncoated coupon during the HCl immersion test. Notice the green liquid? HCl is clear so why is this beaker green? That's the result of chloride corrosion of the stainless surface and metals being leached from the coupon. A great example of metal ion contamination.  The Dursox

The Dursox