High Performance Liquid Chromatography (HPLC) systems are highly sensitive instruments used to separate, identify, and quantify compounds in a sample. However, unwanted metal ion interaction—typically from stainless steel components—can lead to skewed results, peak tailing, and even column degradation. This interaction occurs when metal ions, such as iron, nickel, or chromium, leach from system components into the mobile phase, interfering with analytes and reducing the integrity of the data.

Metal ion interaction is particularly problematic for applications like:

- Biopharmaceutical analysis: Proteins and biomolecules are highly reactive to metal ions, leading to peak distortion or analyte loss.

- Food and beverage testing: Trace metal ions can skew results, potentially leading to regulatory compliance issues.

- Environmental testing: Precision is crucial in detecting contaminants, and metal ion interference can yield inaccurate data.

How SilcoTek Coatings Eliminate Metal Ion Interaction in HPLC

SilcoTek’s chemical vapor deposition (CVD) coatings, like Dursan® and Silcolloy®, provide a non-reactive, inert barrier that prevents metal ion leaching in HPLC systems. These advanced coatings are designed specifically for applications where ultra-high purity is essential, and they offer superior protection against contamination, corrosion, and chemical reactivity.

Here’s how SilcoTek coatings improve HPLC system performance:

1. Inert Surface Chemistry for Minimal Interaction

One of the most significant advantages of SilcoTek coatings is our inert, non-metallic surface. Unlike untreated stainless steel, SilcoTek-coated surfaces prevent any interaction between metal ions and the mobile phase. This ensures the separation process is clean and unaffected by these interactions, which is especially critical in the analysis of biomolecules, organic acids, or chelating agents that can react with metal ions.

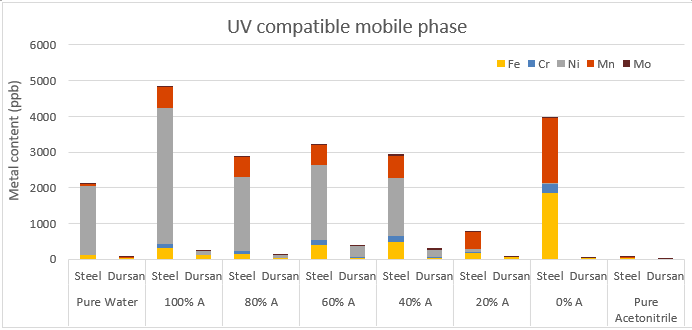

As noted in figure 1 below, the Dursan coated hardware was able to avoid metal interactions better than uncoated stainless steel components in the UV compatible mobile phase. Test parameters are listed below the image.

Figure 1: Mobile phase A: 100 mM Triethylammonium acetate in water. Mobile phase B: 100 mM Triethylammonium acetate in acetonitrile. Temperature: 60°C for 1 week

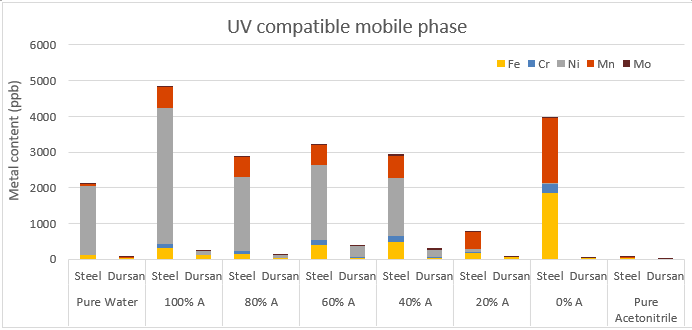

Likewise, figure 2 below shows how the Dursan coated and uncoated stainless steel performed in the mass spectrometer mobile phase.

Figure 2: Mobile phase A: 15 mM Triethylamine with 400 mM HFIP in water. Mobile phase B: Mobile phase A + MeOH (50:50 v/v). Temperature: 60°C for 1 week

Figure 2: Mobile phase A: 15 mM Triethylamine with 400 mM HFIP in water. Mobile phase B: Mobile phase A + MeOH (50:50 v/v). Temperature: 60°C for 1 week

2. Improved Reproducibility and Data Accuracy

In HPLC, consistent, repeatable results are essential. Metal ions in the system can lead to peak broadening, tailing, or even complete analyte loss, all of which compromise reproducibility. By coating critical parts of the HPLC system—such as columns, flow paths, and injection valves—with SilcoTek’s Dursan or Silcolloy, you eliminate these unwanted interactions and ensure more accurate, reliable data.

3. Corrosion Resistance and Longer Equipment Life

HPLC systems often work with aggressive solvents, acids, and bases, which can corrode unprotected stainless steel surfaces over time. As corrosion progresses, more metal ions are released into the mobile phase, further degrading the system's performance. SilcoTek coatings provide exceptional corrosion resistance, extending the life of key components by protecting them from chemical attack. This also reduces the frequency of maintenance and part replacement, saving both time and money.

4. Cleaner Baselines and Reduced Contamination

Metal ion interaction can cause ghost peaks and a noisy baseline, making it difficult to interpret results accurately. With a SilcoTek-coated system, the risk of leaching and contamination is minimized, leading to cleaner baselines and sharper peaks, allowing for easier identification and quantification of analytes.

5. Broad Chemical Compatibility

SilcoTek coatings maintain their integrity across a wide range of solvents and pH levels. Whether you're using acidic or basic mobile phases, SilcoTek coatings remain stable and non-reactive, offering reliable protection regardless of the chemical environment. This is crucial for labs that handle diverse sample types and solvent conditions, as it ensures consistent performance across applications.

Key Benefits of SilcoTek Coatings in HPLC Applications

By applying SilcoTek coatings to your HPLC system, you can enjoy several critical benefits:

- Enhanced analytical accuracy: Eliminate metal ion interference and achieve more accurate, reproducible results.

- Extended column and component life: Protect stainless steel parts from corrosion, reducing wear and tear.

- Increased system uptime: Minimize the need for frequent cleaning or system maintenance due to contamination issues.

- Improved sensitivity for trace analysis: Achieve cleaner baselines and sharper peaks for more precise detection of low-concentration analytes.

- Versatile application: Suitable for both high-throughput systems and specialized, high-purity applications like biopharma and environmental testing.

Case Study: SilcoTek in Pharmaceutical HPLC Analysis

A major pharmaceutical lab was experiencing inconsistent results in their HPLC analyses due to metal ion interaction from stainless steel components. Even after thorough cleaning protocols, ghost peaks and baseline noise persisted, complicating the identification of drug compounds.

The lab decided to coat their HPLC system’s stainless-steel flow paths and valves with Dursan, one of SilcoTek’s most inert coatings. After applying the coating, the lab saw a marked improvement in peak sharpness, with no ghost peaks or tailing in subsequent tests. The data accuracy increased dramatically, enabling more reliable analysis of critical drug formulations. In addition, the coating improved corrosion resistance, reducing the frequency of maintenance and prolonging the life of key system components.

Figure 2:

Figure 2: