Before you say this blog post doesn't apply to me, read on because you'll find this topic to be important to at least some part of your organization.

Yes! Thanks for sticking with us! We're talking about surface fouling, anti-coking, and non-stick surfaces today. If you're thinking that surface interactions causing materials to bind to the surface doesn't apply to me, it can. Surface interaction and related surface energy can have an impact on fluid flow paths in many industries here are some examples:

- Fouling of sample probes in stack and flare sampling can impact test results or cause excessive maintenance issues.

- Protein binding in HPLC and bio-analytical testing can result in carryover and false positive results.

- Aligning surface polarity in polymer manufacturing can be impossible due to surface polarity.

- Fuel injector fouling and fuel line fouling in aerospace and automotive applications can increase maintenance and fuel use.

- Poor mold release in plastic and polymer manufacturing can impact efficiency and part quality.

That's just a few diverse examples of how a sticky surface can increase cost and reduce efficiency and yield in manufacturing operations. Luckily we're here to help! On August 31st we're holding a webinar on how to solve surface fouling with new non-stick coatings. Emphasis on new... SilcoTek has been working hard to evolve and improve our coatings to resist and prevent fouling and coking. Find out about new applications and improved coating performance in our webinar.

Register for our webinar now and learn how SilcoTek coatings

can improve your profitability and efficiency.

SilcoTek® anti-fouling coatings provide the non-stick benefits of PTFE but with greater stability and robustness for your components, especially at high temperatures.

- Improve performance - minimize unwanted build-up with a low-energy surface

- Increase system up-time - fight corrosion and improve chemical compatibility

- Increase durability - replace PTFE with our flexible, high temperature coatings

▼ Click here to see test data for our non-stick surface technology,

including a new prototype coating set to be released in 2018!

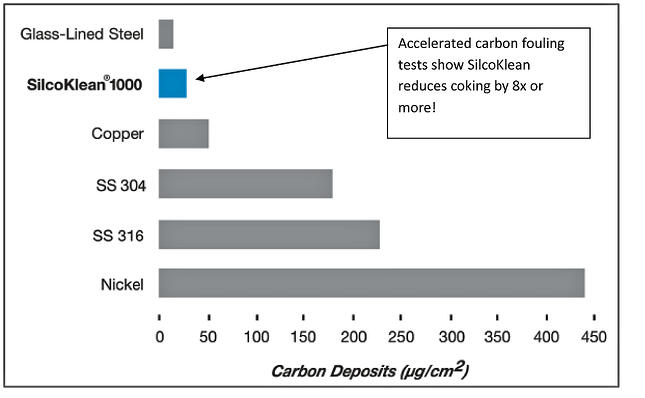

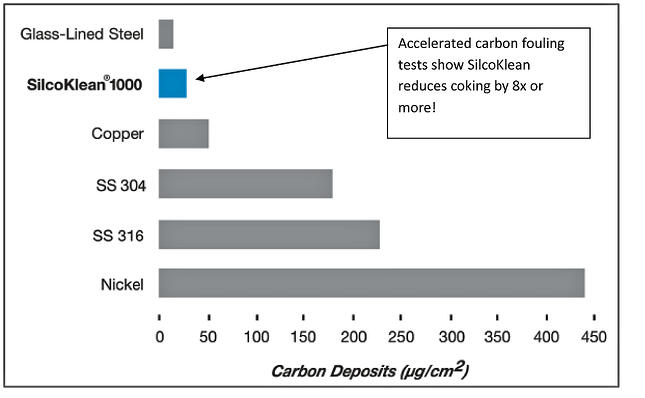

Here's an example of how our coatings can improve performance. A SilcoKlean® coated surface can significantly reduce carbon build-up and fouling by up to 8x on surfaces commonly used in process and aerospace applications.

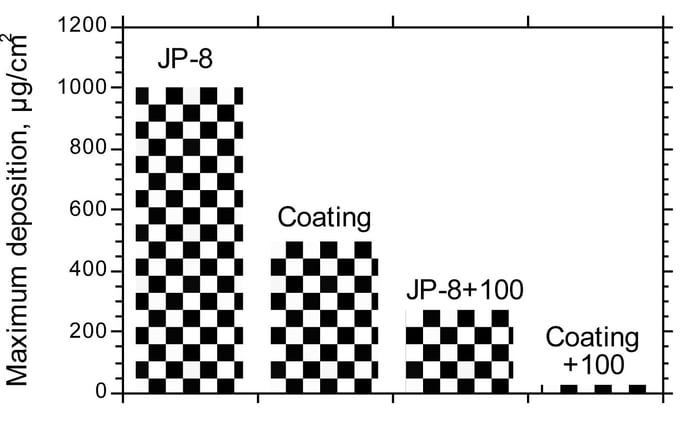

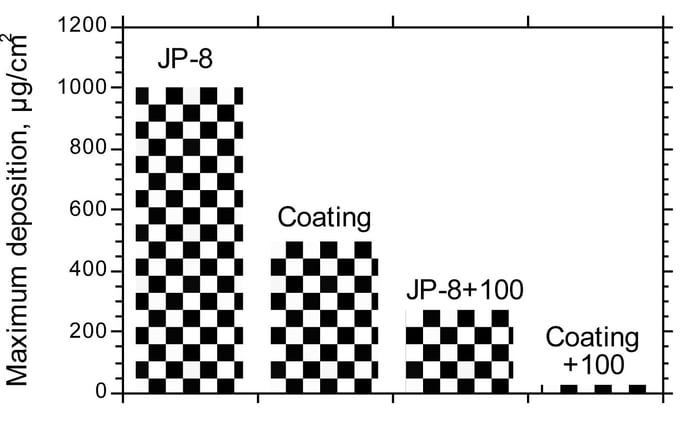

Jet fuel studies have shown that SilcoTek coated surfaces in reduce carbon fouling by orders of magnitude when used in conjunction with fuel additives.*

Jet fuel studies have shown that SilcoTek coated surfaces in reduce carbon fouling by orders of magnitude when used in conjunction with fuel additives.*

Want to read the entire study? Get the Wright-Patterson AFB presentation.

Want to read the entire study? Get the Wright-Patterson AFB presentation.

*Data and image courtesy of Wright-Patterson Air Force Base.

Jet fuel studies have shown that SilcoTek coated surfaces in reduce carbon fouling by orders of magnitude when used in conjunction with fuel additives.*

Jet fuel studies have shown that SilcoTek coated surfaces in reduce carbon fouling by orders of magnitude when used in conjunction with fuel additives.* Want to read the entire study? Get the Wright-Patterson AFB presentation.

Want to read the entire study? Get the Wright-Patterson AFB presentation.