Most part cleaning processes are pretty straightforward and involve some sort of solvent based cleaning system. What about hard to clean or severely stained parts? We discuss how high temperature vacuum annealing can restore and clean parts.

Cleaning Parts with High Temperature Vacuum Annealing

|

In this blog post you will learn:

- How high temperature vacuum anneal cleaning processes can restore a part's finish and thoroughly clean parts.

- Get vendor information about high temperature vacuum annealing.

- Gain an understanding of when it's appropriate to clean parts using vacuum annealing.

|

Background: Cleaning Parts for Silicon CVD Coating Application

SilcoTek® has an extensive surface preparation process that's part of our coating process. Normally parts are sent through an aqueous cleaning process. For more difficult to clean parts, we may pretreat parts or send parts through a more specialized cleaning process. But for stained parts or parts that do not respond to our cleaning methods, there's an alternative to solving product contamination problems. Under certain conditions, SilcoTek may suggest that our customers send their parts through a high temperature vacuum anneal process.

SilcoTek® has an extensive surface preparation process that's part of our coating process. Normally parts are sent through an aqueous cleaning process. For more difficult to clean parts, we may pretreat parts or send parts through a more specialized cleaning process. But for stained parts or parts that do not respond to our cleaning methods, there's an alternative to solving product contamination problems. Under certain conditions, SilcoTek may suggest that our customers send their parts through a high temperature vacuum anneal process.

Conditions for considering vacuum annealing include:

- When the part geometry allows for easy trapping of cleaning fluids and difficult rinsing of the soap solution that is used in SilcoTek’s standard surface preparation step. Example parts are porous ceramic materials and high surface area stainless steel/metallic parts.

- The part contains contamination that cannot be removed by SilcoTek’s standard surface preparation process or other types of usual solution/solvent cleaning methods.

- The coating needs to be stripped off for reworking on high surface area parts, where the parts cannot be subjected to SilcoTek’s standard coating stripping process. This usually is needed for difficult to rinse parts, porous ceramic materials, or high surface area parts as noted above.

Want to learn more about how our coatings perform in your applications? Click the box below to go to our Applications Page.

To ensure all parts meet the cleanliness requirement for our CVD process, SilcoTek relies on our standard surface preparation process to clean most parts before the silicon barrier coating CVD deposition and to strip off coating in cases of reworking. When the standard surface preparation procedures cannot be applied, such as in cases listed above, we recommend a vacuum anneal process as an alternative method to achieve the cleanliness conditions required by the CVD process.

The Vacuum Anneal Process

*

*

Vacuum heat treating companies, like Solar Atmospheres, have developed specialized anneal parameters to treat parts based on material compositions and application requirements. A typical “solution anneal” treatment (also known as “bright anneal”) offered to SilcoTek stainless steel parts will heat the parts in vacuum (£ 10-4 Torr) to 1925 ± 25°F, hold at the peak temperature for 15 minutes, then nitrogen quench to below 175°F. This treatment provides effective cleaning results with minimum risk of oxidation to the stainless steel substrate.

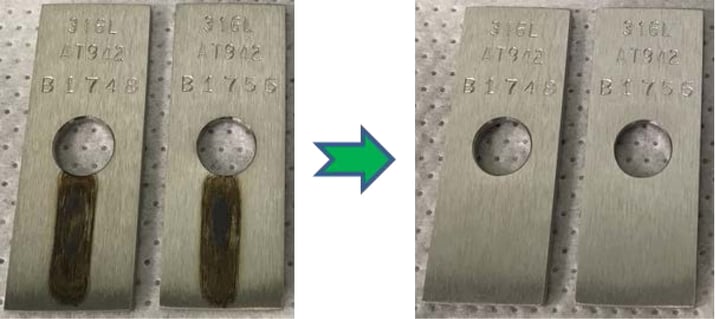

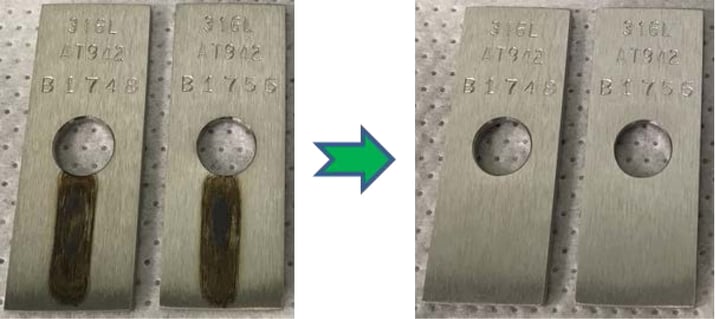

Figure 1 below shows an example of how the vacuum anneal treatment (from Solar Atmospheres) can help to clean up tough contamination on stainless steel. Stainless steel sample coupons, below, were intentionally contaminated and subjected to a high temperature process (up to 450°C) to drive the contamination into the surface of the stainless steel substrate, creating a difficult-to-clean situation. The standard SilcoTek cleaning procedures are found to be ineffective in removing the contaminant marks. However, a solution anneal treatment at Solar Atmospheres completely removed the dark marks as can be seen in the figure below, leaving the substrate surface clean again without signs of oxidation to the stainless steel (i.e. yellow to purple discoloration of the metal).

Figure 1: (Left) intentionally contaminated stainless steel coupons and (right) same coupons after a solution anneal at Solar Atmospheres that returned the coupons to a clean appearance.

Conclusion:

A high temperature vacuum anneal treatment is an effective way to clean ceramic and stainless steel substrate materials as part of an enhanced cleaning regiment and as a surface preparation step before applying the SilcoTek silicon chemical vapor deposition. More information can be obtained by visiting Solar Atmospheres. If your parts fall into one of the categories outlined at the beginning of this blog post, please contact SilcoTek and we will work with you to determine if the vacuum anneal process is a solution for your parts.

Have a question about coating your parts? Contact our Technical Service Team or follow us on LinkedIn.

* Image courtesy of Solar Atmospheres

SilcoTek® has an

SilcoTek® has an

*

*