Silcolloy 2000: New CVD Coating for High Temperature Stability and Corrosion Resistance

Earlier this week, SilcoTek® launched a new coating, Silcolloy® 2000! A few proprietary process changes with drastic performance results gives us the new Silcolloy 2000 coating process. Its excellent corrosion protection and high temperature performance allow customers to achieve the new standard in robust surfaces.

What is Silcolloy 2000?

Silcolloy 2000 can withstand temperatures up to 800° C and performs well in acidic environments. Like other SilcoTek coatings, it will not change your parts' dimensions with a typical thickness range of 180-800 nanometers. High temperature environments such as those found in power and energy, aerospace, and chemical process applications present challenges for material selection. Customers in these and other industries need solutions to extend the lifetime of their products and reduce maintenance caused by extreme temperature and chemical conditions. In response, we developed Silcolloy 2000 to provide the most robust barrier available at temperatures approaching 1000° C. Silcolloy 2000 is an ideal solution for addressing fouling, carbon coking, and mechanical stresses caused by high temperatures.

How is Silcolloy 2000 different from Silcolloy 1000?

Silcolloy 2000 is suitable for all Silcolloy 1000 applications and more. Silcolloy 2000 is an inert coating that improves the corrosion resistance of metals while providing a pure barrier for stopping contamination from metal substrates into process streams. Silcolloy 2000 is specifically designed to provide the above features and benefits at temperatures as high as 800° C, whereas Silcolloy 1000 starts to change and lose its performance between 500-720° C. The surface chemistry is the same high-purity material as Silcolloy 1000, but we have optimized the process for even better surface adhesion, leading to added benefits. Current Silcolloy 1000 users would benefit from transitioning to Silcolloy 2000.

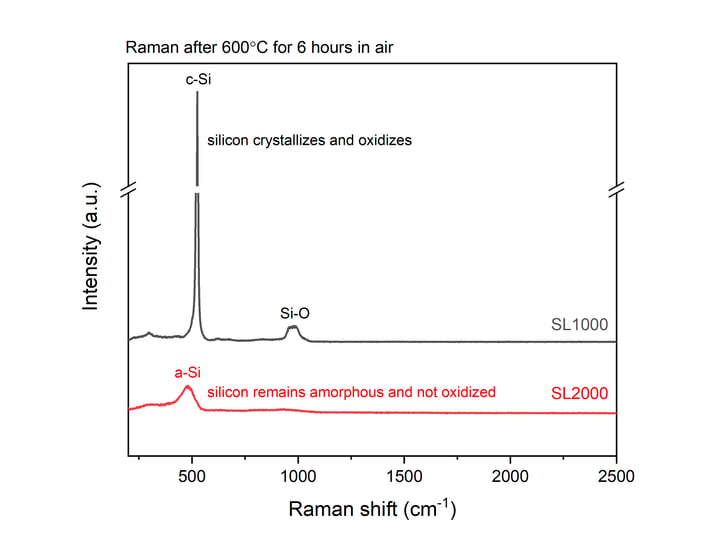

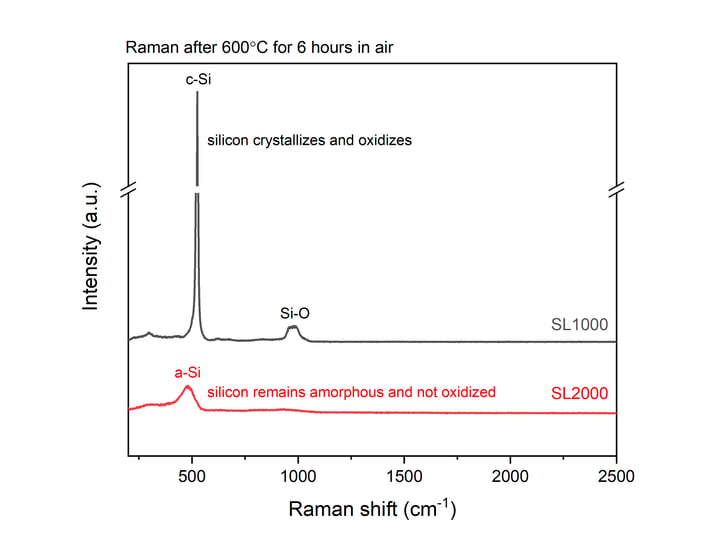

The graph below demonstrates that the silicon remains amorphous and does not oxidize. The improved Silcolloy 2000 process allows our customers to experience high-temperature stability in their applications. The amorphous silicon layer avoids oxidation at high temperatures to improve and prolong performance.

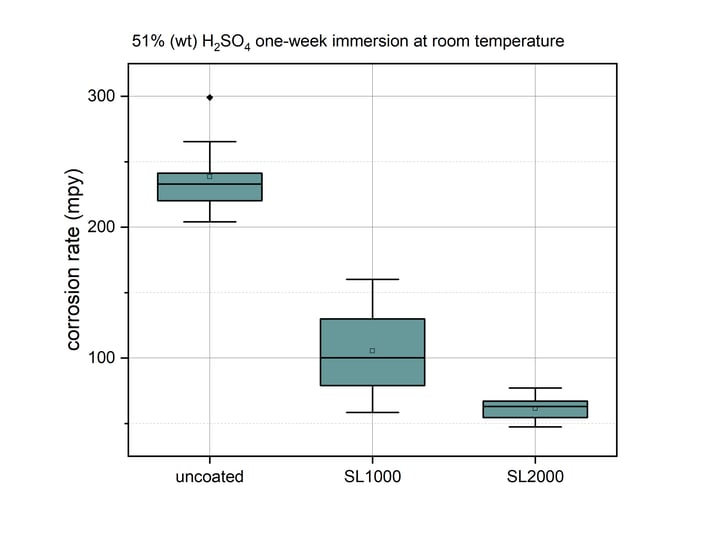

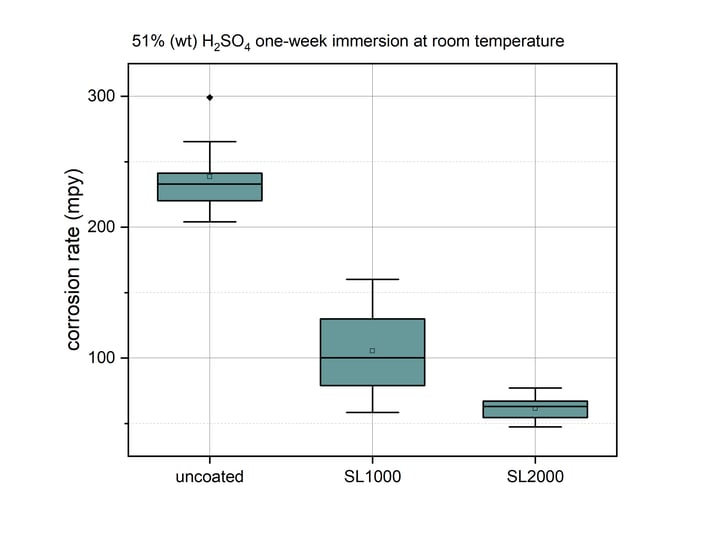

Corrosive agents like sulfuric acid are no match for Silcolloy 2000. The updated standard for corrosion protection performs 4x better than stainless steel and twice as well as its predecessor, Silcolloy 1000. The Silcolloy process has been optimized to outperform prior generations in high temperature environments as well as tough corrosive atmospheres.

Applications & Benefits

- Increase protection against corrosion and metal ion contamination with a non-reactive, pure barrier.

- Achieve better coating adhesion and excellent performance at high temperatures (800° C)

- 3D non-line-of sight process coats all complex geometries including high aspect ratios and small orifices.

- Aerospace components that suffer from carbon coking and mechanical stress at high temperatures

- Process valves, fittings, and tubing that are prone to corrosion from aggressive acids

- Gas delivery parts in semiconductor and chemical manufacturing environments

If you are interested in hearing more about Silcolloy 2000 or ordering, please email our team or visit our website.