It's been a while since we last talked about everyone's favorite nemesis: CORROSION. We have all dealt with corrosion in some form in our lives and in (likely) every occasion, it's frustrating. Corrosion poses a significant threat to numerous industries, causing structural degradation, equipment failure, and substantial financial losses. In the battle against this formidable foe, SilcoTek coatings are a powerful ally, offering a suite of protective measures designed to combat corrosion across various applications and environments.

Understanding SilcoTek® Coatings

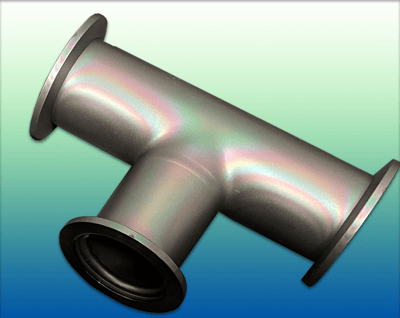

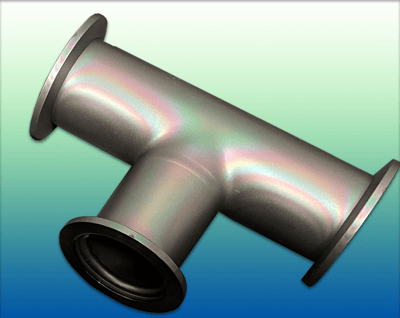

SilcoTek coatings, crafted through the innovative chemical vapor deposition (CVD) process, represent a pinnacle in corrosion-resistant technology. Our coatings are engineered to fortify surfaces against the damaging effects of corrosive elements, acids, bases, solvents, and high temperatures. Our coatings act as a robust defense against corrosion, forming a chemical-resistant barrier that withstands harsh environments. With high-temperature resilience and enhanced durability, these coatings provide a shield against corrosive forces. Their anti-fouling properties prevent contaminants, contributing to system integrity. The increased surface inertness minimizes reactivity, ensuring long-term protection. Customizable to specific needs, SilcoTek coatings emerge as a versatile solution for industries battling corrosion's detrimental effects.

Generally speaking, our coatings all do something different, which means that one coating that may work well in one corrosive environment may not fare as well in another. Here are a couple of examples where our coatings can be utilized for different applications. As always, if you have an application that you think we can help, please collaborate with us to find you the right solution!

Armor Against Corrosion

- Chemical Resistance:

SilcoTek coatings act as a formidable shield, providing exceptional resistance to a wide array of corrosive chemicals. In industries like chemical processing or laboratories, where aggressive chemical environments abound, this resistance becomes invaluable, ensuring the longevity of critical equipment.

- High Temperature Resistance:

Industries operating in high-temperature settings often face accelerated corrosion. SilcoTek coatings, resilient even in extreme heat, safeguard equipment like heat exchangers and exhaust systems, ensuring sustained performance despite challenging thermal conditions.

- Enhanced Durability:

By establishing a stable and robust surface layer, SilcoTek coatings bolster the durability of materials, preventing degradation caused by corrosive agents. This longevity is crucial in harsh environments, protecting outdoor installations or equipment from succumbing to corrosive atmospheres.

- Anti-Fouling Properties:

Certain SilcoTek coatings possess anti-fouling characteristics, deterring the buildup of contaminants. In industries such as oil and gas, where fouling can contribute to corrosion, this property maintains the integrity of critical systems.

- Surface Inertness:

By reducing the reactivity of substrate materials, SilcoTek coatings minimize the likelihood of chemical reactions that lead to corrosion. This increased surface inertness ensures longevity by mitigating corrosive elements’ impact on materials.

- Customization:

The adaptability of SilcoTek coatings allows tailoring to specific applications and substrates. This flexibility enables industries to optimize corrosion resistance for diverse operating conditions and materials. Get in touch with us to discuss your specific application.

In the ongoing battle against corrosion, SilcoTek coatings emerge as a powerful ally defense mechanism, offering comprehensive protection against the detrimental effects of corrosive elements. From chemical resistance to high-temperature durability, these coatings exemplify innovation, fortifying industries across the spectrum.

Our Most Corrosion Resistant Coatings:

Silcolloy 2000®:

Silcolloy coatings offer the highest temperature stability of all SilcoTek solutions while simultaneously preventing corrosion and contamination from metal, glass, and ceramic substrates. These coatings are made up of several layers of high-purity silicon (Si), the same material used to make semiconductors, which provides a dense film that effectively shields coated parts from their process environment. Silcolloy is widely used as a solution to improve the chemical compatibility of various materials and help stainless steel perform like corrosion resistant superalloys, creating significant cost savings for customers in semiconductor, laboratory, energy, and many other industries.

Dursan®:

Dursan is a proprietary, patented, NSF certified and FDA compliant process designed to improve the inertness, durability, hydrophobicity, fouling and corrosion resistance of products ranging from precision instrumentation to severe industrial applications. SilcoTek's patented chemical vapor deposition (CVD) process bonds the Dursan coating to stainless steel, alloy, ceramic, and glass, making a high tolerance durable coating even under extreme temperatures and pressures. Redefine material limitations with Dursan by improving chemical and corrosion resistance, durability, and release properties.

Siltride®:

Siltride coatings are comprised of amorphous silicon oxynitride (a-SiOXNY:H), a robust chemistry that substantially improves corrosion resistance, hardness, wear resistance, and electrical resistivity. As SilcoTek’s most hydrophilic or “water-attracting” coating, Siltride 1000 boasts a water contact angle as low as 10°, making it ideal for improving the surface properties of critical process flow paths in medical devices, life sciences instrumentation, and oil and gas facilities. New Siltride coatings are SilcoTek’s best solution for the most demanding applications.

In essence, SilcoTek coatings are not merely protective layers; they are the defenders of longevity, reliability, and cost-effectiveness in an ever-evolving industrial landscape, ensuring that materials and equipment stand resilient against the relentless forces of corrosion.

This blog post aims to highlight the expertise of SilcoTek coatings in combatting corrosion across industries. It emphasizes the specific attributes and benefits of these coatings, showcasing their role as a vital solution for safeguarding materials and equipment from the detrimental effects of corrosion.

Keep up with the latest SilcoTek news by subscribing! Click the link below to sign up.