On September 18th, 20th, and 21st, SilcoTek's Dr. Jesse Bischof will be attending Biotech Week in Boston, Massachussetts, specifically BioProcess International (BPI). The event will be held at the Boston Convention and Exhibition Center. It will include several events during the week, including topics like cell and gene therapy manufacturing and commercialization, next generation protein therapeutics, medical education and grants, and what's new in biomedical devices, among others.

Dr. Bischof will also be attending International Society for Pharmaceutical Engineering (ISPE) on Wednesday, September 19th at Gillette Stadium, also in Boston. ISPE will feature learning opportunities about the latest technologies and regulations, as well as networking with fellow pharmaceutical industry professionals.

BioProcess International boasts that they provide a space for attendees to "access the science, technologies and contacts you need to improve efficiencies across all phases of biopharmaceutical development and production."

The main objectives of BPI are to provide a platform for sharing the latest scientific advancements, fostering collaboration and partnerships, and facilitating discussions on emerging trends and challenges in the biotech and life sciences sectors.

Attendees at BPI include scientists, researchers, entrepreneurs, executives, investors, and professionals from various organizations and institutions within the biotech and life sciences ecosystem. The event offers a valuable opportunity for learning, networking, and staying updated on the latest developments in the industry.

Dr. Jesse Bischof, Ph. D., R&D Scientist

Please join Dr. Bischof as he presents his poster on Tuesday, September 19th and 3:30-3:45 PM on poster screen 1.

The Importance of Limiting Metal Ion Leaching in BioProcessing

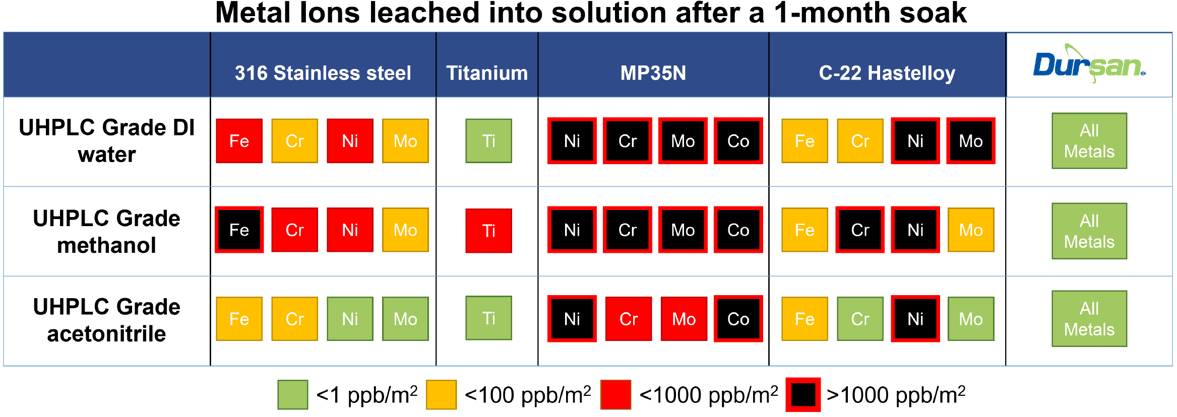

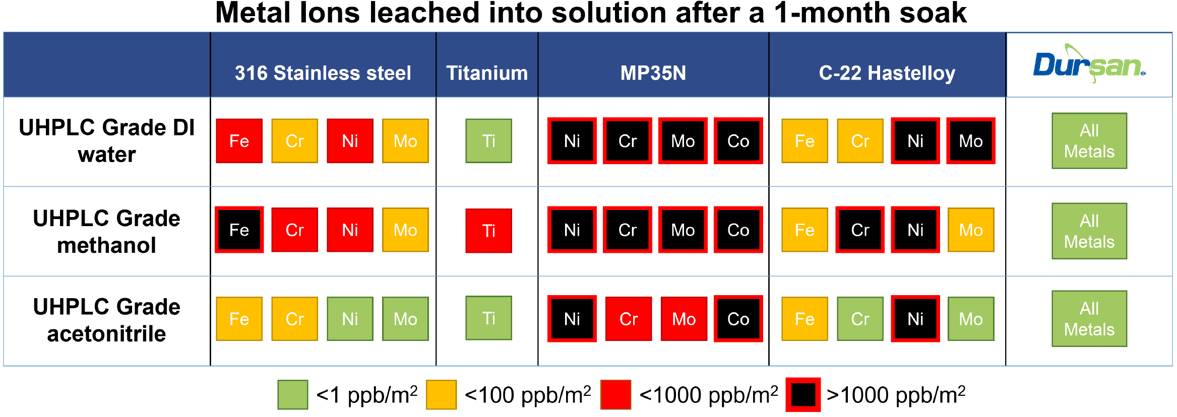

In the bioprocessing industry, fluidic pathways made of various alloys can leach metal ions into production processes. Metal ion species can significantly impact both upstream and downstream processes, affecting product quality and stability. The goal is to quantify metal ion leaching from common alloys and limit it with a silica-like coating deposited via SilcoTek's patented Chemical Vapor Deposition (CVD) coating process.

Metal ions, especially trace metals like iron, chromium, nickel, molybdenum, and zinc, can catalyze reactions that lead to product degradation or impurity formation. Some have little to no impact to production while others can cause upstream irregularities. Irregularities can compromise the quality, safety, and efficacy of biopharmaceuticals or other bioprocessed products. Ensuring low metal ion levels is crucial for maintaining product integrity.

Metal ion leaching can also corrode equipment and pipelines in bioprocessing facilities. This can lead to equipment failure, contamination of the product, and costly maintenance and replacement. Addressing issues related to metal ion contamination can be expensive. It may involve using more expensive materials, coatings, or purification processes to reduce metal ion levels. Minimizing these costs is essential for the economic viability of bioprocessing operations.

That is where SilcoTek® comes in...

SilcoTek's Dursan® coating is ideal to combat obstacles in bioprocessing. Addressing the challenges posed by metal ion leaching, corrosion, equipment failure and replacement, downtime, costly repairs, etc., SilcoTek can help bioprocessing manufacturers have a smoother process with benefits like:

-

Corrosion Resistance: SilcoTek coatings, like Dursan, provide excellent corrosion resistance. They form a protective barrier on metal surfaces, preventing the leaching of metal ions into the process stream. This is crucial for maintaining the purity of the product and extending the lifespan of equipment.

-

Reduced Metal Ion Leaching: SilcoTek coatings significantly reduce the leaching of metal ions from stainless steel and other alloys. This is particularly important in bioprocessing, where metal ion contamination impacts product quality, cell culture, and downstream purification steps.

-

Improved Product Quality: By minimizing metal ion contamination, SilcoTek coatings help ensure consistent and high-quality bioprocessed products. This is especially critical in the pharmaceutical and biotechnology industries, where product quality and safety are paramount.

-

Biocompatibility: SilcoTek coatings are designed to be bioinert, meaning they do not interact with biological substances. This property is essential in bioprocessing to avoid interference with cell cultures, enzymatic reactions, or product formulations.

-

Extended Equipment Lifespan: Coating equipment and components with SilcoTek coatings can extend their lifespan by protecting them from corrosion and wear. This reduces maintenance costs and downtime associated with equipment replacement.

-

Enhanced Cleanability: Dursan coating is hydrophobic and anti-stick, making equipment surfaces easier to clean. This is crucial for maintaining hygienic conditions in bioprocessing, where cleanliness is essential to prevent contamination.

-

Temperature Stability: SilcoTek coatings can withstand high temperatures, making them suitable for various bioprocessing applications, including those involving elevated temperatures such as fermentation.

-

Regulatory Compliance: SilcoTek's Dursan coating meets regulatory standards for biocompatibility, making it compliant with industry regulations according to NSF certifications. This ensures that Dursan's use in bioprocessing applications aligns with regulatory requirements.

-

Cost-Effective Solution: In addition to the substantial benefits in terms of equipment protection and product quality, SilcoTek coatings can also be a cost-effective solution compared to using more expensive materials or alternative coatings.

-

Application Versatility: SilcoTek coatings can be applied to various types of equipment and components, including tubing, valves, reactors, and chromatography columns, making them versatile for a wide range of bioprocessing applications.

SilcoTek performed a 6 part series of experiments testing metal ion leaching in DI water, methanol, and acetonitrile with various substrates. The results of Dr. Bischof's findings are noted below.

To read the latest publication of Dr. Bischof's study on metal ion leaching, click the link below.

Controlling and minimizing metal ion leaching in bioprocessing is crucial for maintaining product quality, safety, and consistency, as well as complying with regulatory standards. It directly impacts the efficiency of the process, the integrity of the final product, and the overall cost-effectiveness of bioprocessing operations. SilcoTek coatings can improve your processes and save you valuable time, money, and hassle.

For questions about SilcoTek's coatings and services, please reach out to our technical service team for more information!