In the realm of industrial and consumer products, the widespread presence of per- and polyfluoroalkyl substances (PFAS) has long been a cause for concern due to their links to health and environmental issues. SilcoTek, a pioneer in environmentally friendly coatings, offers a game-changing alternative to PFAS-based coatings such as PTFE (Teflon®). Let's explore how SilcoTek's innovative CVD coatings are reshaping industries and setting new standards for sustainability and performance.

The PFAS Predicament

Per- and polyfluoroalkyl substances are prevalent in our daily lives, from cosmetics and non-stick cookware to other applications like weatherproof clothing. The wide-ranging use of PFAS has led to detectable levels in human blood, animal tissues, and the environment, prompting regulatory agencies like the EPA and ECHA to propose limitations on their usage.

Among the commonly used PFAS, PTFE plays a significant role as a coating in industrial processes. However, the need for a sustainable alternative has never been more pressing.

SilcoTek's Sustainable Advantages Over PFAS

SilcoTek's Chemical Vapor Deposition (CVD) coatings allow for a shift towards sustainability. Here's why SilcoTek coatings stand out as superior alternatives to PFAS:

-

Earth-Friendly Composition: SilcoTek coatings are crafted from the fundamental elements of the Earth—silicon, oxygen, carbon, and hydrogen. Importantly, they steer clear of fluorinated chemicals, solvents, and materials requiring special disposal.

-

Enhanced Performance: SilcoTek coatings exhibit superior temperature stability, flexibility, and density compared to PFAS, making them ideal for diverse applications requiring durability in varying conditions.

-

Chemical Inertness and Corrosion Resistance: These coatings are chemically inert, outperforming fluoropolymers in creating barriers between sample streams and active metals. Additionally, they boast high corrosion resistance.

-

Exceptional Adhesion: SilcoTek's CVD coating process ensures molecular adhesion to substrates, providing unmatched adhesion over PFAS coatings. Coated parts maintain their ability to bend and flex without the risk of damage or flaking. Not to mention, they also provide a completely coated surface due to the deposition process. Even complex geometries, tubing, and small parts can be evenly coated.

SilcoTek Coatings Are Already at Work

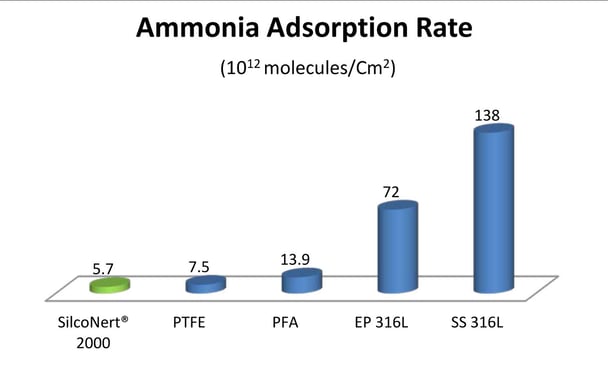

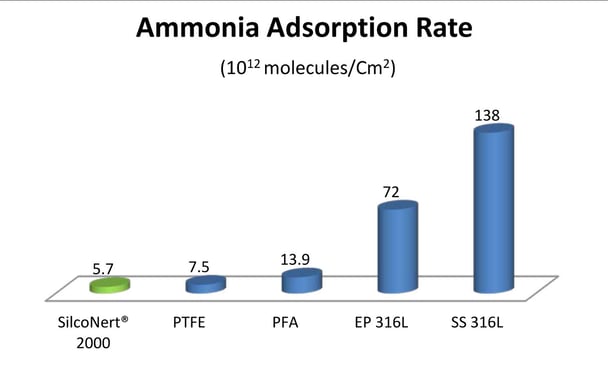

Ammonia Adsorption

Accurately measuring trace levels of ammonia can be a daunting task due to its highly reactive nature with stainless steel. This becomes especially crucial in processes such as petrochemical refining and hydrogen production. However, our coatings provide a solution by remaining inert to trace levels of ammonia. So, you can rely on our coatings to ensure precise measurements and maintain the integrity of your processes.

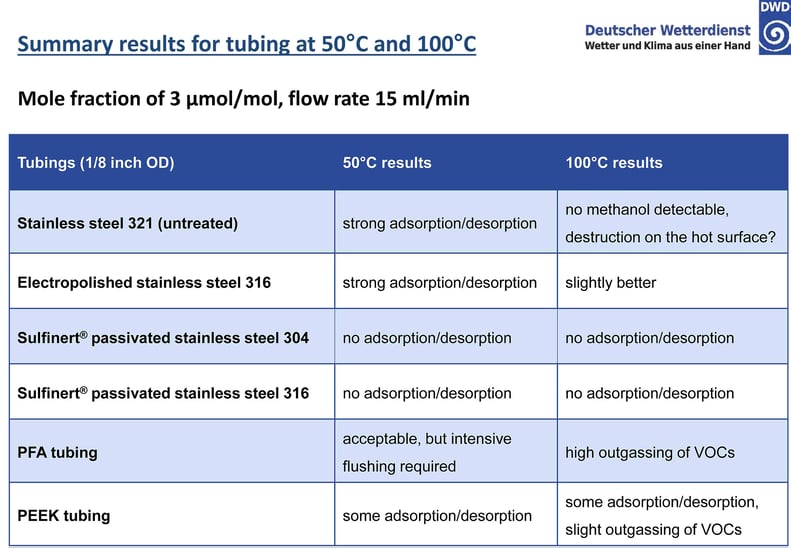

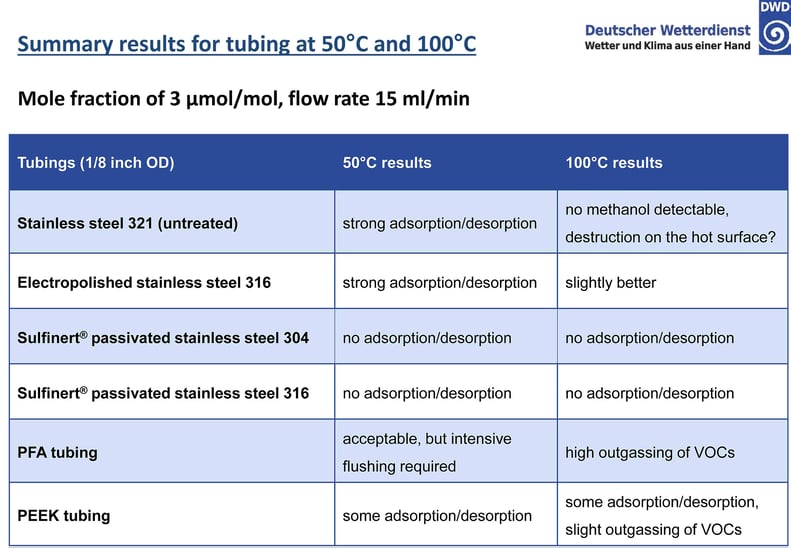

VOC Adsorption

This table nicely demonstrates the superiority of our coatings compared to PFA, a PFAS. Particularly at higher temperatures, you can see a clear decline in performance with this material. The issue of permeation at elevated temperatures is a significant challenge with PFAS coatings, which our coatings alleviate. This advantage is one of the most notable and impactful aspects of our innovative solutions.

Applications Across Industries

Leading global companies and research organizations are actively adopting SilcoTek's CVD coatings across various industries. Here are some notable applications:

-

Process Systems: Tubing, piping, heat exchangers, and instrumentation benefit from SilcoTek coatings' enhanced durability and chemical resistance.

-

Chromatography: Liquid and gas chromatography columns experience improved performance with SilcoTek coatings.

-

Valve Components: Valve bodies and components, including moving internal parts, benefit from enhanced durability and chemical resistance.

-

Medical Devices: SilcoTek coatings prove invaluable in medical devices and clinical instrumentation, ensuring inert and corrosion-resistant surfaces.

-

Sensors and Probes: Coating sensors and probes enhances their performance across various industries.

-

Food Processing: Surfaces of hoppers, chutes, augers, and more in food processing benefit from SilcoTek coatings' suitability for contact with consumables.

-

Pharmaceutical and Beverage Production: Flow path components in the production of pharmaceuticals, food, and beverages witness improved sustainability and performance.

-

Packaging: Components of packaging materials can be coated for enhanced performance and sustainability.

A Greener Future with SilcoTek

SilcoTek's CVD coatings emerge as a beacon of hope in the quest for sustainable alternatives to PFAS. As industries strive to minimize their environmental footprint, the adoption of these coatings represents a decisive step towards a greener future without compromising on performance. With SilcoTek, it's not just a coating—it's a commitment to sustainability and excellence. The age of PFAS dominance is giving way to a new era of responsible innovation with SilcoTek leading the charge.

Want to know how SilcoTek's PFAS alternatives can fit into your application? Contact us!