During a conversation with a customer, a question about our Silicon Coating Material Compatibility Guide came up that I couldn´t answer. So I asked our R&D scientist Dr. Min Yuan to answer the question. Here's what she said.

The Customer Question

Why is it that we cannot coat nickel but recommend vacuum nickel brazing. Furthermore we say that we see excellent results with Hastelloy® (up to 74% nickel) and Inconel (over 70% nickel) but on the other hand Monel (2/3 Nickel & 1/3 copper) is not treatable. Why?

Here's Dr. Yuan's Response.

These are really good questions. First let's briefly discuss the nature of metal alloys.

About alloys and why they make a difference in coating results.

I'll do my best to make this as painless as possible. An alloy is a mix of a base element metal with another element (or elements) that can mix with the base metal when molten. Metal alloys can often have quite different properties than their base metal. In the case of alloys, two wrongs can often make a right. For example aluminum and copper are pretty soft metals, but mix them you get an aluminum alloy that's stronger.

I'll do my best to make this as painless as possible. An alloy is a mix of a base element metal with another element (or elements) that can mix with the base metal when molten. Metal alloys can often have quite different properties than their base metal. In the case of alloys, two wrongs can often make a right. For example aluminum and copper are pretty soft metals, but mix them you get an aluminum alloy that's stronger.

The same goes for iron mixed with a touch of carbon. Carbon's not even a metal but mix a touch of it with iron and you get steel which can have all sorts of benefits like greater strength. Throw in a bit of chromium into the mix and the resulting stainless steel will vastly improve corrosion resistance.

Well we have the same issues and benefits of alloys going on here. Only we're talking about the coatability of nickel vs. nickel alloys.

Confused about what we can coat? Get our quick reference Material Compatibility Guide.

Why can't we coat nickel?

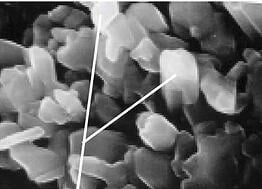

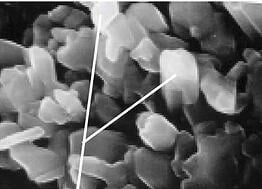

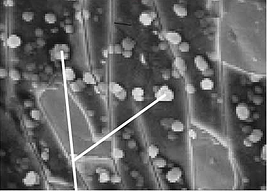

Our process is incompatible with pure nickel, because it induces a different growth mode and does not produce the typical nice amorphous (unstructured or non crystalline) coating we see on a stainless steel substrate. You see silicon is happy to bond and diffuse into all sorts of metals, glass or ceramic surfaces but it preferentially does not bond particularly well with nickel. In fact after the first few silicon atoms bond to the nickel surface, the following silicon atoms prefer to bond to themselves rather than to the nickel. The result? Under magnification you'll see lots of silicon columns with deep voids, almost like skyscrapers in a big city. That's not a good coating because chemicals you're interested in testing can hide in the valleys or corrosive chemicals can attack the exposed surfaces. The SEM image below is a general example of what columnar growth looks like under magnification. See? Kind of like big buildings.

Our process is incompatible with pure nickel, because it induces a different growth mode and does not produce the typical nice amorphous (unstructured or non crystalline) coating we see on a stainless steel substrate. You see silicon is happy to bond and diffuse into all sorts of metals, glass or ceramic surfaces but it preferentially does not bond particularly well with nickel. In fact after the first few silicon atoms bond to the nickel surface, the following silicon atoms prefer to bond to themselves rather than to the nickel. The result? Under magnification you'll see lots of silicon columns with deep voids, almost like skyscrapers in a big city. That's not a good coating because chemicals you're interested in testing can hide in the valleys or corrosive chemicals can attack the exposed surfaces. The SEM image below is a general example of what columnar growth looks like under magnification. See? Kind of like big buildings.

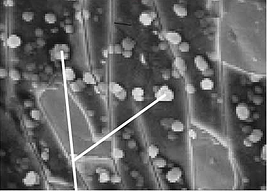

Our amorphous coating when applied to stainless steel, glass, ceramics or many metal alloys will bond uniformly to the surface and build a coating layer-by-layer over the entire surface. It will look something like this SEM image below (note silicon particulates on the surface).

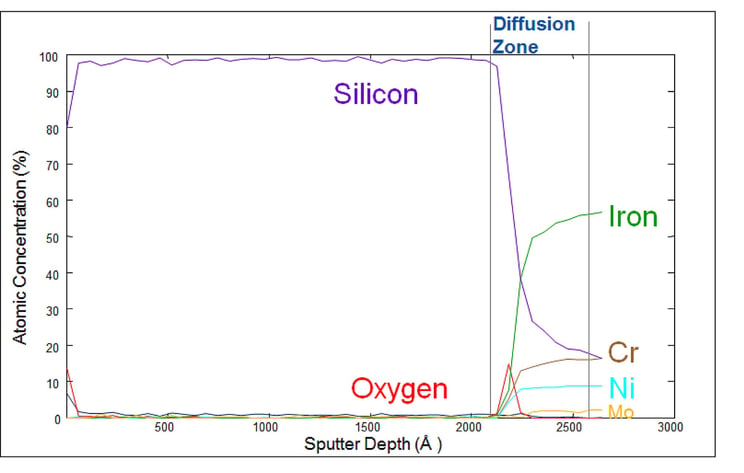

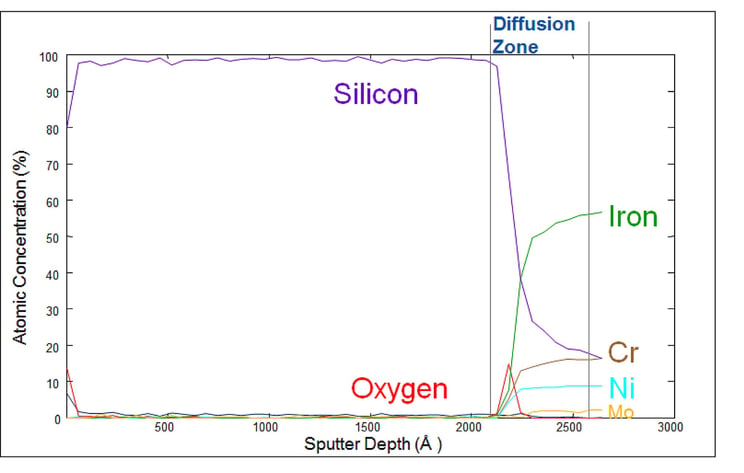

The Auger plot below shows how our silicon coatings bond to the surface. Auger electron spectroscopy (AES) sputter depth profile analysis quantifies the material composition and diffusion zone characteristic of our silicon CVD coatings (in this case our inert SilcoNert® coating). The plot shows a layer of approximately 2000 angstroms (200 nm) of silicon. Note the approximately 500 angstrom diffusion zone between the stainless steel surface and the silicon coating. An Auger depth profile of a coated nickel part would show areas with little to no coating while other areas would have a much greater depth profile.

Back to alloys.

In cases where nickel is alloyed with other “stabilizing” elements, such as Cr (chromium), Si (silicon), P (Phosphorus) etc., even when nickel (Ni) is the major component base metal, our process coats beautifully over these alloys (e.g. Hastelloy®, Inconel, or typical nickel brazing filler alloys such as Ni-Cr-P or Ni-Cr-Si-P). In these cases, the coating is able to bond to the "more beneficial' alloy despite the Ni base metal because the alloy characteristics will allow silicon to more easily or preferentially bond to the surface uniformly. So that's why we can coat superalloys and Ni brazing material.

You can't win them all!

In cases where nickel is alloyed with another difficult to coat element, such as copper, there is no “stabilizing force” or synergy to allow our CVD coatings to bond to the surface. A copper nickel alloy is usually incompatible with our process. Monel is such an example. Nickel and copper by itself are both incompatible with our process, so when you combine these two into Monel, it is incompatible as well.

Check out our international reps!

By the way, did you recognize the city skyline? That's Hong Kong! Why mention it? Because we have been actively signing international reps. especially in the Asia region. Want to see where our reps are? Go to our international sales rep page to see a listing of our sales force world wide. Just click the map below to see our reps. Now customers in Asia and Europe can easily contact a local rep who understands the local or regional issues and can give more direct, and personal service.

I'll do my best to make this as painless as possible. An

I'll do my best to make this as painless as possible. An