Inert silicon coatings, like Dursan, solve problems in a wide range of industries. We discuss solutions and benefits coatings offer in medical diagnostic applications.

Solving Common Problems in Medical Diagnostics

The Dursan coating process is one of SilcoTek's most versatile offerings and is successful in a wide range of industries. Min Yuan, our SilcoTek researcher, will be explaining why these characteristics are so valuable in the medical device manufacturing industry.

|

In this blog post you will learn:

- How silicon coatings like Dursan help to improve medical diagnostic testing.

- How coatings improve corrosion resistance and component durability

- How non stick and inert Dursan can prevent carryover, contamination and sample adsorption.

SilcoTek Remains Open, Supporting COVID-19 Efforts

Click here to read our latest COVID-19 Update.

|

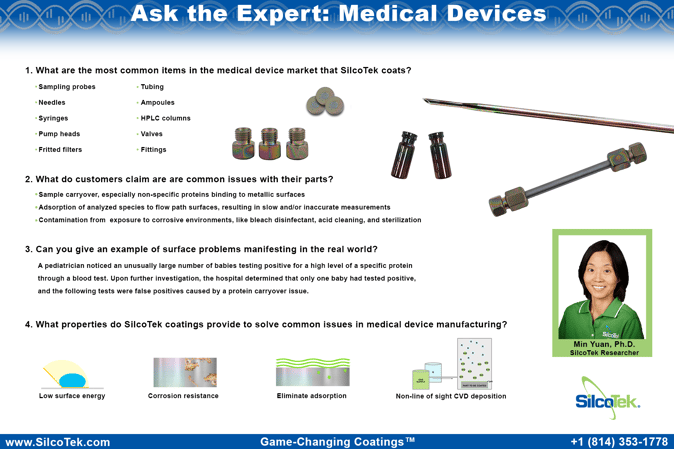

Our expert, Dr. Min Yuan, has worked closely with many medical device manufacturing companies and different government agencies to ensure Dursan is robust and accurate for our customers. The Dursan process is NSF certified and FDA compliant. SilcoTek coatings are vital to medical devices, but they solve problems in a variety of other applications, too.

Common issues solved by silicon coatings.

Let's discuss some common problems and solutions that CVD coatings can solve. But first I'd like to highlight a real world problem relating to medical diagnostics equipment and carryover.

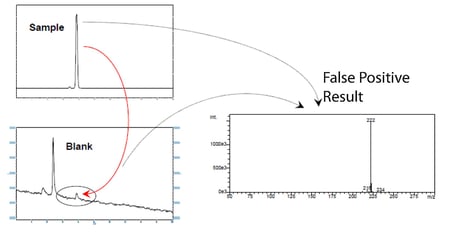

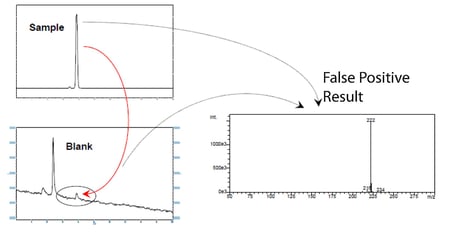

A real world problem

Carryover and contamination is a persistent and real world problem. Here's a real world example of how contamination issues can take a real financial and emotional toll. A pediatrician noticed an unusually large number of babies testing positive for a high level of a specific protein through a blood test. Upon further investigation, the hospital determined that only one baby had tested positive, the follow-on tests were false positives caused by a protein carryover issue in the test system. The additional testing and evaluation cost the hospital a lot of time and money. While on a human scale a false positive diagnosis can cause real emotional trauma to patients and patient families.

Solving Problems

SilcoTek coatings solve several common problems relating to medical diagnostics and sample transfer including:

- Sample carryover (especially non-specific protein binding)

- Adsorption resulting in slow and inaccurate results

- Contamination from harsh environments

We'll discuss each of these issues and present data showing how inert coatings improve material performance.

Sample Carryover

Carryover is the result of a sample binding to the flow path surface which then releases or elutes during a later sampling event. The result is that peaks from the previous analysis may appear in later test results. The carryover contamination may corrupt many later tests, causing a group of positive results.

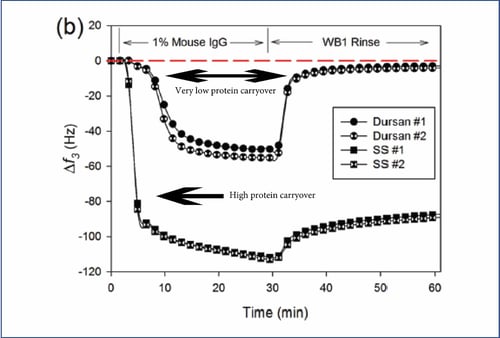

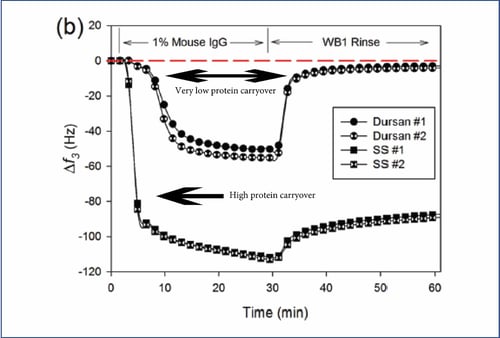

A recent study by Abbott Laboratories in Applied Surface Science demonstrates the inertness performance and corrosion resistance of inert silicon coatings. Comparative QCMD (quartz crystal microbalance with dissipation monitoring) characterization of SilcoTek's Dursan coating shows significant reduction in protein surface retention, preventing carryover and potential false positive test results.

The graph below shows the Dursan® surface (top line) returns to baseline weight after contact with the test protein analyte. The bottom line shows the stainless steel surface retaining the protein sample and not returning to baseline weight; indicating retention of protein. Read the entire paper.

How Dursan® works.

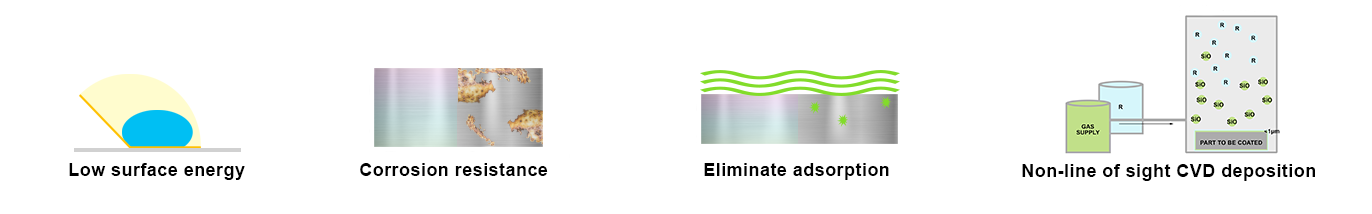

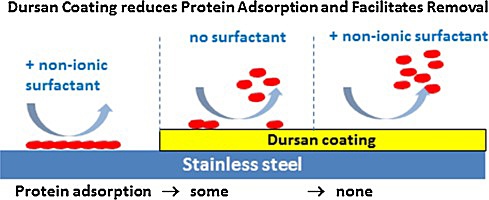

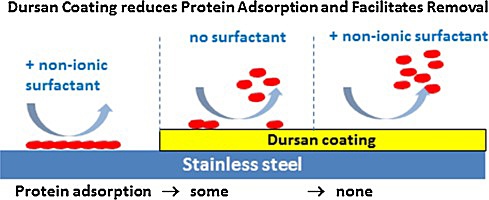

Dursan® is a very low surface energy, bio-inert coating designed to reduce non-specific protein binding and carryover while improving corrosion resistance in biotechnology, HPLC and pharma applications.

Preventing buildup or fouling in flow paths will improve test accuracy and system flow performance. Dursan facilitates surfactant rinse performance; eliminating the potential of contaminant buildup. Benefits of an anti-fouling surface include:

- Proteins, blood, and bio-molecules should not stick to the coated surface.

- A non-stick surface will improve analytical sensitivity and reliability

- Increase device/instrument up-time and overall efficiency.

- Allow for easy and complete rinsing with a non-ionic surfactant.

The benefit? Sample carryover is virtually eliminated, preventing false positive or erroneous results. Yes lab productivity is improved but the real benefit is prevention of expensive followup patient care and testing.

Learn More About

Bio-Inert Coatings

Corrosion

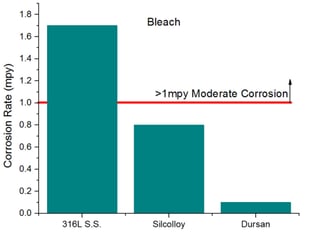

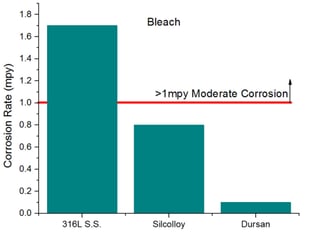

Corrosion can also cause carryover and test errors. Pitted corroded needle and sample pathways can trap protein molecules and later release trace contaminants in subsequent tests. A corrosion resistant surface stops pitting and protein carryover. Dursan® coated surfaces resist corrosives commonly used in bio analytical and LC applications. Chlorides (like HCl) and bleach can corrode stainless steel flow paths, causing ion contamination and pitting of the LC flow path. A metal free corrosion resistant coating like Dursan prevents contamination of the test sample.

Get Our Latest Corrosion

Solutions Presentation

A pitted surface can impact analyte flow, hide trace contaminants and result in excessive maintenance or system failures. Dursan's corrosion resistant surface prevents interaction with stainless steel surfaces, improving HPLC and medical diagnostic tubing corrosion resistance by an order of magnitude.

Comparative ASTM bleach immersion studies show Dursan prevents surface attack by preventing interaction of corrosive analytes or cleaning agents with the surface; outperforming other coatings or stainless steel surfaces by an order of magnitude.

Adsorption

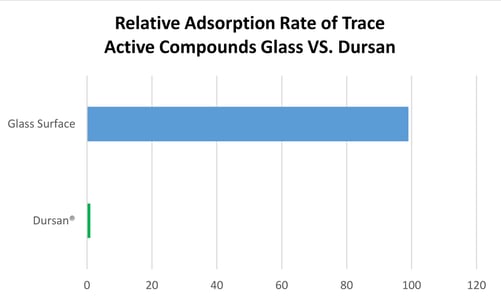

Inert and non-reactive surfaces will prevent the retention of analyte materials to the surface. Materials like glass, ceramics, stainless steel, and to some degree PTFE and PEEK can under various conditions retain or react with analyte compounds. CVD coatings like Dursan prevent the interaction of the test compounds with the flow path surface.

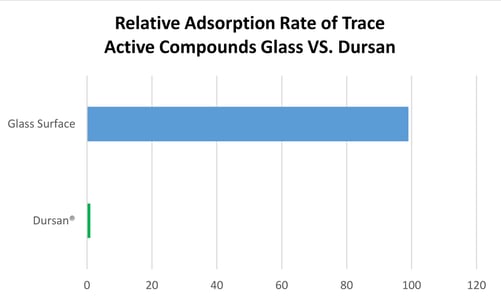

The graph below highlights the inertness of Dursan compared to a glass surface. Reactivity of the glass surface results in the loss of nearly all the trace compounds tested. Dursan does not react with test materials which allows nearly all the analyte to reach the column and detector.

Coating Applications in Medical Diagnostics

Common Parts that Benefit from SilcoTek® Coatings

|

Needles

Probes

Sensors

Tubing

Ampoules

Fritted Filters

|

Filters

Valves

Vessels/Reactors

Fittings

HPLC Columns

LC Pump Heads

|

Want to learn more about SilcoTek? Read our coating E-book.

Are you interested in learning more about our coatings for medical devices? Check out our specific applications page.

Our monthly Ask the Expert series on LinkedIn features our R&D team answering a few questions about a set topic each month.