Our marketing team (myself included) has put a lot of time into developing resources and content for SilcoTek.com that aims to help you learn more about our coatings and how they can benefit a variety of applications. But we know one thing for sure: swimming through the abundance of content and finding exactly what information you need isn't always easy.

That's something we're continuing to work on, but for now we want to share content that will help you choose the best coating option. Our next webinar on Thursday, September 17th at 2pm EST is completely dedicated to giving you all the insights you need to make the right decision. In the meantime, I wanted to share 3 quick tips for picking the SilcoTek coating that will maximize your performance most.

1. Establish your detection limit.

If you're analyzing the content of something, decide how "low" you need to go. At parts-per-million levels or lower, you will need to use SilcoNert 2000 or Dursan to get good results.

2. Know the pH.

Dursan is the only coating we offer that is suitable for the full pH range 0-14. While SilcoNert 2000 slightly edges Dursan in terms of inertness, any base (pH > 8) will degrade a Silco- layer.

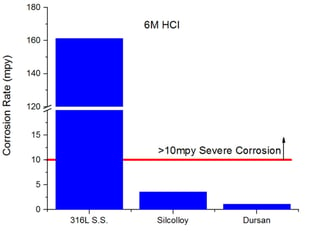

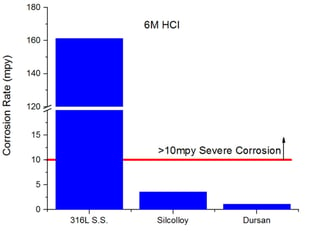

3. Mind corrosion.

| Corrosion doesn't just happen on big structures. Whether trace HCl is corroding your sample transfer tubing or your instrument is 20 feet under the surface in a salty part of the Gulf, corrosion is harming your equipment. Dursan and Silcolloy each have different corrosion resistant properties, so register for our webinar to learn more about the details on which one to choose. |

|

These are just 3 of many ways to decide what coating you need for a variety of applications. Sometimes multiple (or no) coatings work, so we will dive into much greater detail next month in the webinar presentation.

I hope to "see" you there!