Yes! SilcoTek® does offer NSF approved & FDA compliant coatings. Our Dursan® coating is certified by NSF International and therefore is FDA compliant. Often customers will ask "Is Dursan FDA approved?" That question and specifically the term "FDA approved" requires a more thorough discussion and explanation.

What does FDA Approved mean?

......................Nothing since FDA does not specifically approve coatings.

The United States Food and Drug administration (FDA) does not formally "approve" coatings or other materials for food or bio/pharmaceutical contact. Rather, the FDA regulates coatings via the Code of Federal Regulations (CFR), specifically 21 CFR 175.300 which lists what raw materials are acceptable and unacceptable for the formulation of coatings. It is then up to the coating supplier to self-regulate to ensure that they are using raw materials that are acceptable.

According to the FDA, a coating must:

1) Pass the solvent extraction tests listed in 21 CFR 175.300.

2) Contain no heavy metals.

3) All coating components must conform to the materials listed by the FDA in order to be compliant.

These stipulations are also required for NSF/ANSI 51 certification. Dursan® successfully meets these requirements and is therefore FDA compliant.

With respect to pharmaceutical applications, our data suggest that Dursan® does not "alter the safety, identity, strength, quality, or purity of the drug product beyond the official or other established requirements" per 21 CFR 211.65.

Nevertheless, we strongly encourage customers to test the use of Dursan® in their specific application to verify that performance requirements are met and the customer's production processes and outputs can continue to meet FDA approval guidelines.

How Does Dursan Benefit LC and Medical Devices?

Dursan acts as a mirco-thin inert barrier, preventing sample or product contact with reactive base materials. Dursan is a precision coating that does not significantly impact tolerances but can be applied to intricate parts like needles. Key Dursan benefits are:

Improved corrosion resistance means less pitting and flowpath contamination.

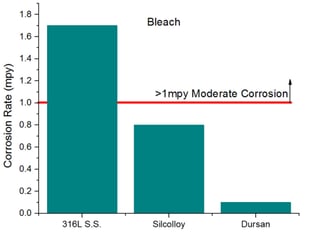

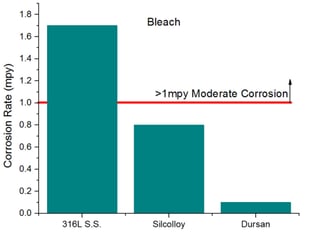

Dursan resists many corrosives commonly used in medical diagnostics and HPLC applications like hydrochloric acid and bleach. In fact Dursan will prevent surface pitting even after hundreds of cleaning immersion cycles. Comparative tests show Dursan improves corrosion resistance by an order of magnitude over uncoated stainless steel.

Immersion of stainless steel in bleach can result in fluid contamination as illustrated in this immersion test. The bleach in this photo is contaminated by the corroded stainless steel, turning the beaker contents dark green.

Dursan coated samples do not contaminate the bleach, assuring an uncontaminated flowpath and true-to-test results.

Learn how to make HPLC and medical diagnostics instruments true-to-test.