H2S scavenging in oil and gas downhole sampling tools can have a significant impact on the ability of producers to accurately assess the safety, quality and value of a well. Vladislav Achourov, Adriaan Gisolf (Schlumberger); Dave Goodwin, Tim Pritchard (BG Group), in their presentation " Focused Sampling For Low H2S Quantification", (Devex-Conference.org) outline the challenges and impact of material surfaces on H2S scavenging. They demonstrate nearly 90% loss of H2S within 10 minutes of exposure to uncoated surfaces.

The study went on to show SilcoTek® coated flowpath surfaces demonstrate "98% retention of approximately 50ppm by volume H2S concentration after 6 days of sample storage".

Actually, we can do better. SilcoNert® 2000 is proven to retain nearly 100% of sulfur compounds for up to 14 days, at concentrations as low as 11 part-per-billion!

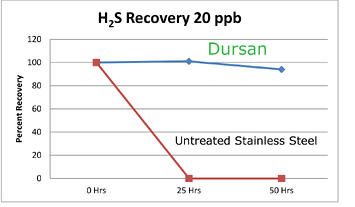

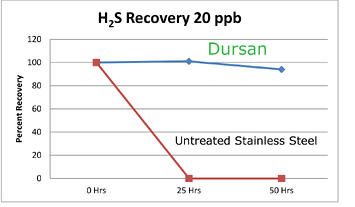

Our new coating Dursan® demonstrates higher durability and nearly the same sulfur sampling inertness as SilcoNert® 2000.

SilcoTek® coatings are a game changer for oil and gas sulfur management in upstream downhole applications. Our coatings enable the producer to:

- Accurately assess sulfur & mercury concentrations downhole and on the surface.

- Prevent hazardous unintended exposure due to inaccurate sampling.

- Properly value a well before production.

- Manage produced water in the field.

- Allow field technicians the option to test on site or in the lab.

Coating Applications

To assure an inert sample pathway, coat the entire flowpath. Uncoated components can adsorb sulfur compounds and significantly impact sample results. Sample concentrations up to 200ppm have been significantly degraded due to a single uncoated flowpath component.

| Probes |

Tubing & Fittings |

| Sample Receptacles |

Scavenging Components |

| Sample Fluid Analyzer |

SPMC |

| MPSR |

Constant Pressure Sample Bottles |

Want to learn more about our coatings? Contact our Technical Service Staff at Silcod@SilcoTek.com or see us at Gulf Coast Conference, October 20th and 21st in Houston, TX.