Tier 3 gasoline standards are looming on the horizon. By 2017 refiners will be required to reduce sulfur in gasoline from the tier 2 level of 30ppm to an average of 10ppm.

The EPA anticipates refiners will need to make "minimal" changes to operations in order to meet the new standard; refiners beg to differ. Refiners anticipate they'll need to expand hydrotreating processes (especially in naptha produced in fluidized catalytic cracking (FCC) units). Refiners expect to shell out up to $10 billion in upgrades and an additional $2.1 billion per year in operating costs; overall project duration of 2+ years is expected. So now's the time to begin Tier 3 planning.

With major capital projects in the works it's easy to forget one important aspect of compliance, the sampling system. The lower the sulfur detection limit, the greater the impact of any active sites in the sample flowpath. What was thought to be a minor source of sulfur adsorption/loss under Tier 2 will become a major issue under Tier 3. The impact of a single adsorption site under Tier 3 could be the difference between compliance and a major shutdown.

With major capital projects in the works it's easy to forget one important aspect of compliance, the sampling system. The lower the sulfur detection limit, the greater the impact of any active sites in the sample flowpath. What was thought to be a minor source of sulfur adsorption/loss under Tier 2 will become a major issue under Tier 3. The impact of a single adsorption site under Tier 3 could be the difference between compliance and a major shutdown.

SilcoTek® coatings are a major asset in achieving Tier 3 refinery compliance. Inert coatings like SilcoNert® 2000 and Dursan® coat the entire sample pathway to assure an inert flowpath.

Ultimate inertness

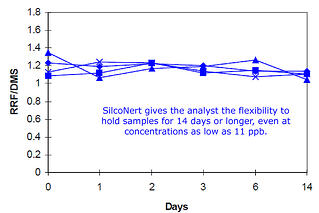

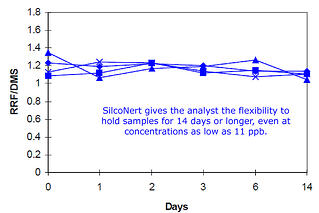

SilcoNert® 2000 prevents adosrption of H2S and other compounds in sample cylinders, tubing and other sampling surfaces. In fact SilcoNert is so effective in preventing H2S loss that samples can be stored for 14 days or longer without loss of sample integrity. Without SilcoNert, the sample would be completely adsorbed into the stainless steel sample cylinder within hours.

Incomparable response

The old adage, do you want it right or do you want it now has been turned on it's head. SilcoTek coatings allow operators to get the sample right and now!

Response time through SilcoNert® coated tubing is reduced to seconds compared to hours for uncoated tubing. A near zero adsorption surface allows refiners, coal operators, and oil & gas professionals to immediately assess and correct for changing process conditions. Failure to react in a timely manner can cost refiners and other operators millions in shutdown costs or product quality issues.

Response time through SilcoNert® coated tubing is reduced to seconds compared to hours for uncoated tubing. A near zero adsorption surface allows refiners, coal operators, and oil & gas professionals to immediately assess and correct for changing process conditions. Failure to react in a timely manner can cost refiners and other operators millions in shutdown costs or product quality issues.

The Old Sulfur Management Ways Won't Cut It.

Hoping to avoid coating the entire sample flowpath? Prepare for major headaches. The sampling methods used for 30 to 50ppm sensitivity most likely will not produce meaningful sample results. Here are a few that won't cut it:

- Priming, forget it. At 10ppm an uncoated fritted filter will adsorb active compounds like sulfur for months before you get a signal.

- Uncoated fittings? One uncoated fitting will adsorb a significant amount of H2S.

- Rusty sample cylinders? Acive compunds will be adsorbed by rust particles, making sampling an exercise in futility.

- Steam cleaning with dirty steam? Particulates in steam will adsorb acive sample compounds. Another source of futility.

- Untreated filters? Fritted filters have a huge surface area. Not coating that filter will result in adsorption of most if not all the sample.

- Uncoated regulators? Even components with a brief exposure to the sample will impair quality.

- Uncoated analyzer tubing. Just a few inches of uncoated stainless steel tubing can result in loss of sample.

Why take the risk? SilcoNert® 2000 and Dursan® are proven to improve sensitivity and response. Coating the entire sampling flowpath will assure compliance and allow operators to focus on operations, not troubleshooting an unreliable sampling system.

With major capital projects in the works it's easy to forget one important aspect of compliance, the sampling system. The lower the sulfur detection limit, the greater the impact of any active sites in the sample flowpath. What was thought to be a minor source of

With major capital projects in the works it's easy to forget one important aspect of compliance, the sampling system. The lower the sulfur detection limit, the greater the impact of any active sites in the sample flowpath. What was thought to be a minor source of

Response time through SilcoNert® coated tubing is reduced to seconds compared to hours for uncoated tubing. A near zero adsorption surface allows refiners, coal operators, and oil & gas professionals to immediately assess and correct for changing process conditions. Failure to react in a timely manner can cost refiners and other operators millions in shutdown costs or product quality issues.

Response time through SilcoNert® coated tubing is reduced to seconds compared to hours for uncoated tubing. A near zero adsorption surface allows refiners, coal operators, and oil & gas professionals to immediately assess and correct for changing process conditions. Failure to react in a timely manner can cost refiners and other operators millions in shutdown costs or product quality issues.