Over the years, many inert coating solutions have been developed to enhance sampling system compatibility with reactive compounds like H2S and mercury (Hg), such as polytetrafluoroethylene (PTFE), siloxane, and chemical vapor-deposited silicon-based coatings. Complex sampling requirements found in oil & gas prove that no single solution exists, but pairing a high performance coating with proper base material selection will ensure a reliable quantification of oil and gas yield composition.

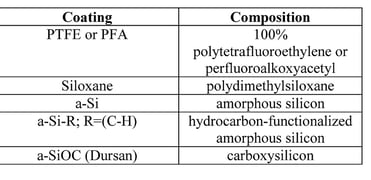

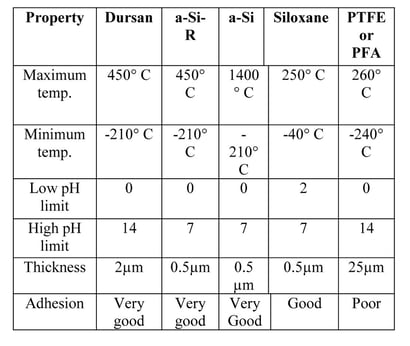

The variety of materials available to solve sampling system compatibility problems are listed below. Some are specific to pH range tolerances while others provide higher thermal stability or specially-tailored surface chemistry specific to certain critical analytes.

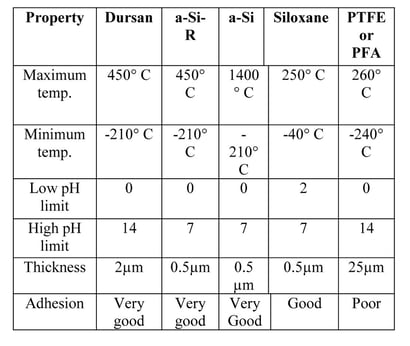

Selection of required material properties is often derived from the most significant failure mode in the application. Abrasion and wide pH exposure in oil and gas sampling applications limit the potential solutions that can be used. For example, significant wear or vibrations result in poor performance for PTFE coatings, however PTFE is one of only two options discussed here that is suited for pH 0-14. The table below summarizes some of the most important surface physical characteristics in oil and gas service.

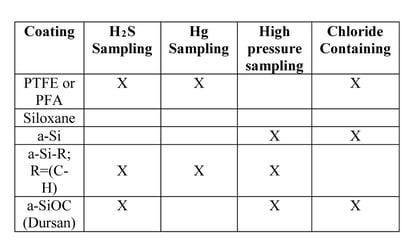

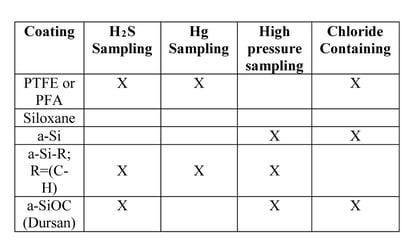

The final and most critical criterion to the selection of an appropriate surface for sample stream components is the chemical compatibility with critical compounds and corrosive media involved in the sample extraction process. The table below briefly summarizes compatibility in common sampling applications (note: <ppm levels of H2S and Hg). Inertness in these applications is critical for accurate qualification of oil and gas fields and, additionally, mitigating potential corrosion. These factors have a significant impact on both the quality of the final product and the project’s bottom line.

It is clear that, specifically for sampling potential oil and natural gas yields, only PTFE/PFA and the amorphous silicon-based coatings are suitable for maintaining an inert barrier between trace levels of H2S and the metal substrate. Further, only Dursan® exhibits the necessary combination of robustness and chemical inertness for repeated, reliable sampling of H2S in the abrasive conditions present in oil and gas fields.