Wear is a Nightmare

Wear can cause problems in most applications and can be frustrating, expensive, and time-consuming to deal with. We were curious about the wear resistance of our coatings and took a closer look at 5 of them. Our researchers have data to determine which of these 5 coatings provide the best wear resistance in comparison to an uncoated sample, which is detailed below.

Why is This Important?

From the cost of replacements to down-time profit loss, wear and abrasion can be a serious headache. Our coatings are designed to improve chemical compatibility, corrosion resistance, and surface energy. Due to the extremely thin profile of our coatings (all less than 2 microns thick), we are usually not the best option for physically aggressive applications where extremely hard materials are required. That said, SilcoTek’s coatings are used in a variety of industrial applications with challenging conditions that require the coating to withstand handling, wear from moving parts, and particulate abrasion. We work with leading manufacturers of products like valves that have moving internal components and require a coating to withstand the movement.

In a previous similar experiment (check out the Featured Content to the right), we compared 3 SilcoTek coatings. Dr. Min Yuan took a look at how hardness and wear resistance are measured and calculated. In the previous blog post, we are discussing RD5, which we are now marketing as Siltride.

Synopsis

This blog reports the results of pin-on-disk wear tests of five SilcoTek® coatings: Silcolloy® 1000, Dursan®, SiltrideSM, RD13 and RD14, along with uncoated control samples. Results from two sets of test conditions were reported, and samples were analyzed with profilometry, SEM and EDS techniques to obtain wear track volumes and coating integrity information after wear. The tested coatings were ranked in terms of wear performance based on the analysis results.

Siltride is a new silicon-oxy-nitride coating that will be commercially available in the coming months! Stay tuned for more information on Siltride. RD13 and RD14 are experimental coatings used in this trial, which are still in the development state with our research teams here to help solve specific problems. RD14 is a hydrocarbon-functionalized carbosilane deposition, where as RD13 is a hydrogenated, amorphous silicon-rich silicon oxynitride (a-SiOx Ny :H). If you have questions about these particular coatings, please reach out to us!

Background

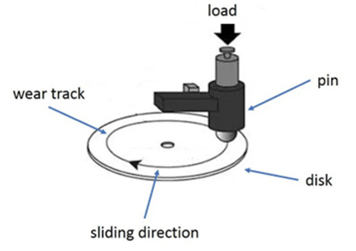

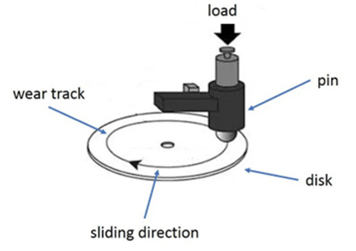

Pin-on-disk is a widely used technique to evaluate tribological properties of thin protective films. The measurement is usually carried out using a tribometer as depicted in Figure 1 below, with the sample mounted on a rotating stage and a stationary pin pressed against the sample surface (the rotating disk) under a given load to create a wear track. The most common shapes for the pin are spherical (ball) or cylindrical due to ease of alignment. The volume of the wear track (material lost) is measured to calculate the wear rate of the film material, and under identical test conditions, can be used to compare the wear resistance of different films.

Five SilcoTek coatings (Silcolloy 1000, Dursan, Siltride, RD13 and RD14), along with uncoated control samples were independently tested via pin-on-disk by the Tribology/Materials Processing Laboratory at the Pennsylvania State University. Post-test samples were analyzed using profilometry and SEM/EDS techniques to quantify the wear track volume and assess coating integrity. The test results are reported in this blog and the five coatings are ranked in terms of their wear performance based on the analysis results.

Figure 1: A schematic diagram of a pin-on-disk test1

Data and Discussion

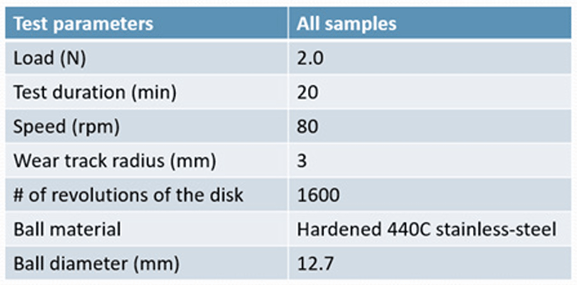

Electropolished 316L stainless-steel coupons (2.25” L x 2.25” W x 0.03” D) were used as substrates in this study. Coupons went through SilcoTek’s standard surface preparation and coating processes for each individual coating type. Uncoated control samples were sent through the standard surface preparation but not the coating process.Testing was conducted on a Bruker UMT TriboLab tribometer equipped with the pin-on-disk module at room temperature in ambient air, and a hardened 440° C stainless-steel ball was used as the pin in the test. Sample wear tracks were analyzed using a KLA Tencor P16+ profilometer to measure wear track crosssectional areas, and a Thermo Fisher Scientific Apreo SEM equipment equipped with an EDS analyzer to assess coating integrity after wear. Wear rate was calculated from the measured wear cross-sectional area.2 Two different test conditions were used for wear evaluation of the coatings and the results are reported below.

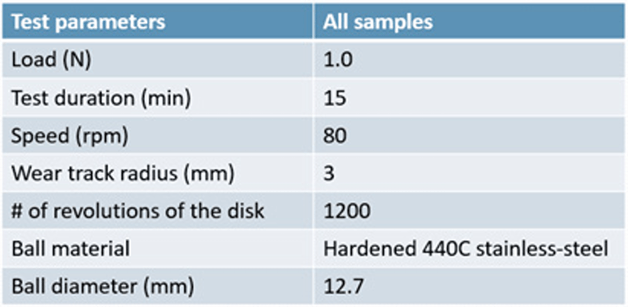

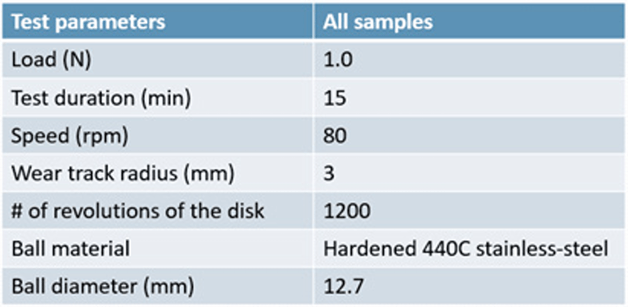

1. Test condition 1: 1N force and 15 minutes test duration

Table 1: Pin-on-disk test condition 1

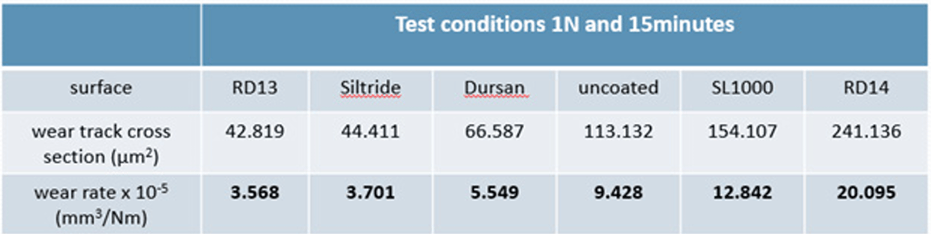

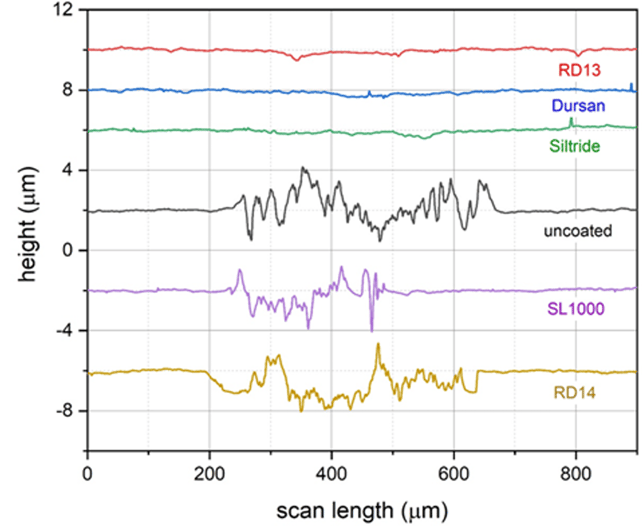

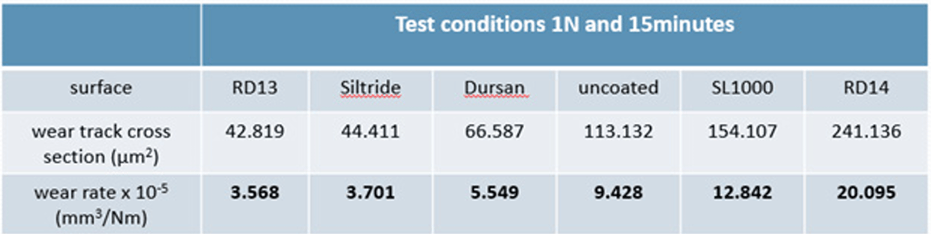

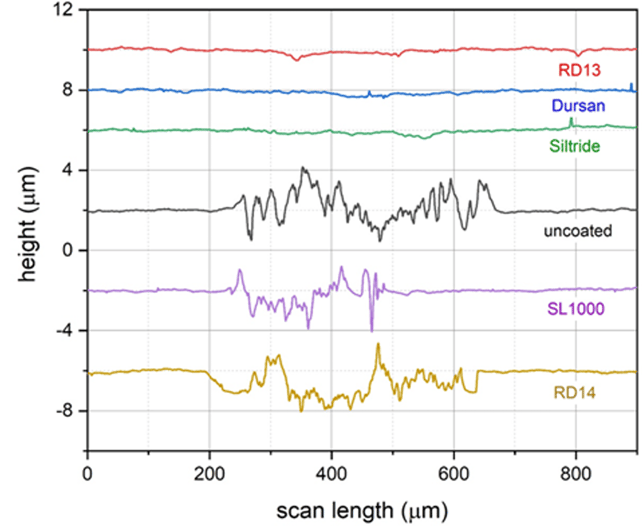

The test parameters for condition 1 are outlined in Table 1. Three coupons from each coating type as well as the uncoated control were tested under condition 1. The average value of the three samples for each tested surface is reported in Table 2 below, along with the corresponding wear rate calculated from the wear track cross sectional area.2 Figure 2 shows the wear track cross sectional profile comparison of the six surfaces. Dursan, Siltride, and RD13 showed much smoother wear tracks than the other three surfaces, indicating less material loss hence higher wear resistance.

Table 2: Average wear track cross sectional area and corresponding wear rate for each tested surface

Figure 2: Wear track cross sectional profile comparison of the six tested surfaces (1N and 15 minutes)

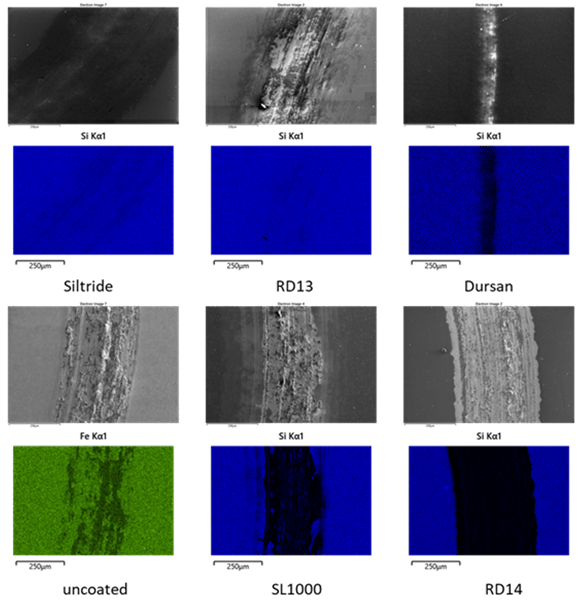

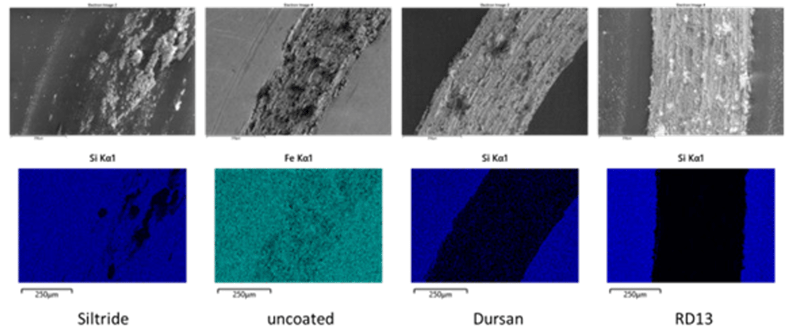

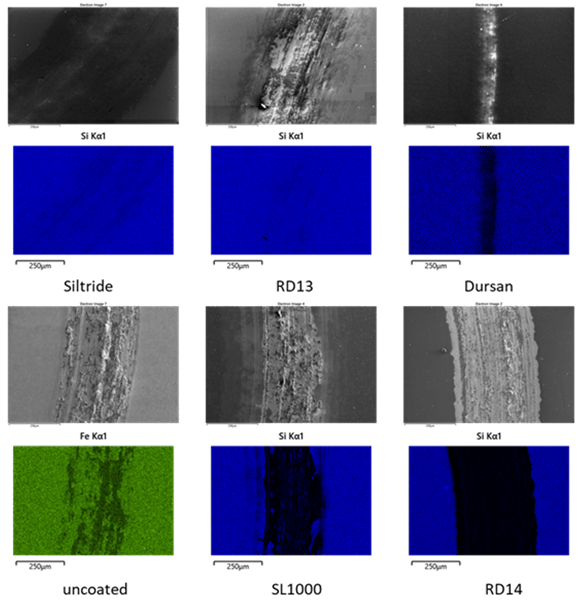

The post-wear samples were also analyzed using SEM and EDS techniques to assess the wear track appearance and coating integrity. Figure 3 shows the SEM images of the six surfaces after test (grey images; all taken at 500x magnifications) and their corresponding silicon EDS maps (blue maps for the coated samples and green iron map for the uncoated control). A lack of blue in the EDS map indicates coating loss as a result of the pin-on-disk test. While the uncoated control, SL1000 and RD14 all showed considerable material loss in the EDS maps, Siltride and RD13 showed minimal coating loss and Dursan showed an arrow wear track with a small amount of coating loss. These observations agree well with the profilometry results reported in Figure 2, confirming that Siltride, RD13, and Dursan are the three top performers under test condition 1.

Figure 3: Wear track of the six tested surfaces under SEM (grey images; all taken at 500x magnifications) and silicon EDS maps showing coating coverage after test (coated samples in blue silicon EDS maps and the uncoated control in green iron map)

2. Test condition 2: 2N force and 20 minutes test duration

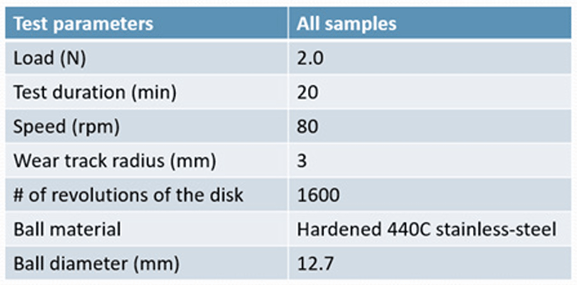

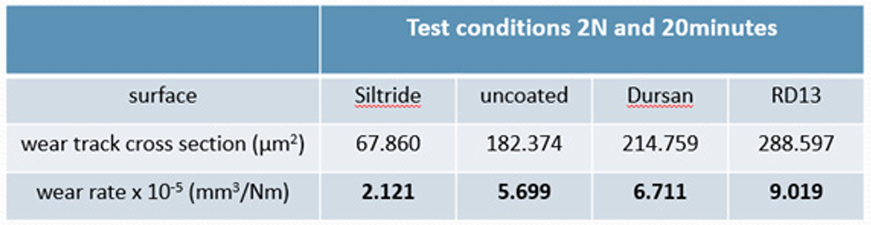

Table 3: Pin-on-disk test condition 2

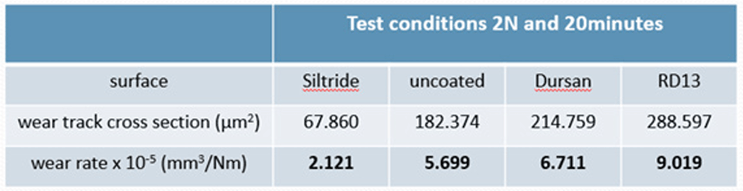

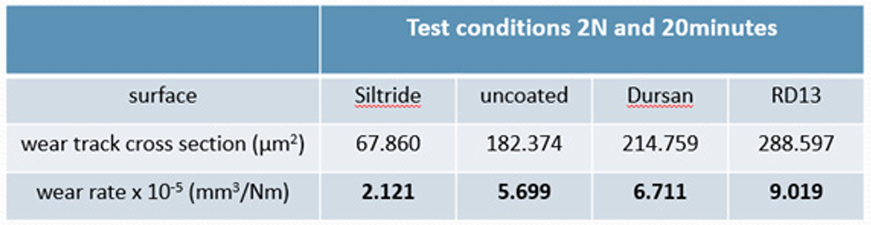

The test parameters for condition 2 are outlined in Table 3. Only the three top performers in test 1 and the uncoated control were tested under condition 2, and one sample was tested per surface type. The wear track cross sectional areas and their corresponding wear rates are reported in Table 4 below. Figure 4 shows the wear track cross sectional profile comparison of the four surfaces. Siltride showed smoother wear track profile and outperformed the other three surfaces in terms of wear resistance.

Table 4: Average wear track cross sectional area and corresponding wear rate for each tested surface

Figure 4: Wear track cross sectional profile comparison of the four tested surfaces (2N and 20 minutes)

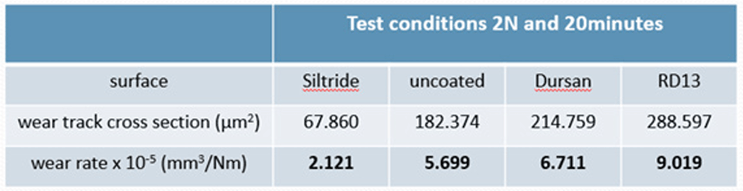

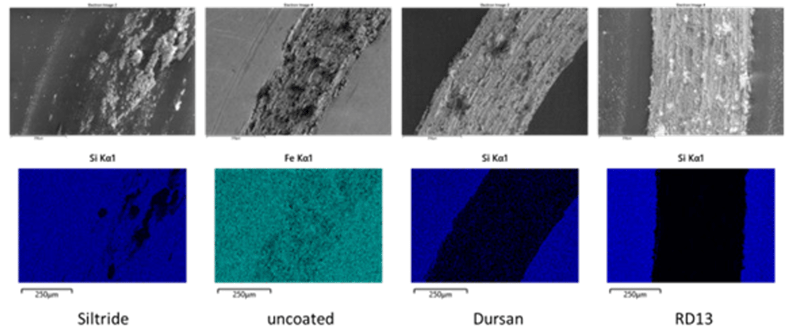

The post-wear samples were again analyzed using SEM and EDS techniques to assess the wear track appearance and coating integrity. Figure 5 shows the SEM images of the four surfaces after test (top row;all taken at 500x magnifications) and their corresponding EDS maps (coated samples in blue silicon maps and the uncoated control in teal iron map). A lack of blue in the EDS map indicates coating loss due to the pin-on-disk test. The results correspond well with the profilometry results reported in Figure 4. Siltride showed some coating loss but overall much better integrity than Dursan and RD13 under test condition 2.

Figure 5: Wear track of the four tested surfaces under SEM (top row; all taken at 500x magnifications) and EDS maps (bottom row) showing coating coverage after test (coated samples in blue silicon EDS maps and the uncoated control in teal iron map)

Figure 5: Wear track of the four tested surfaces under SEM (top row; all taken at 500x magnifications) and EDS maps (bottom row) showing coating coverage after test (coated samples in blue silicon EDS maps and the uncoated control in teal iron map)

Summary

This blog reports the pin-on-disk wear test results of five SilcoTek coatings (Silcolloy 1000, Dursan, Siltride, RD13 and RD14), along with uncoated control samples. The pin-on-disk test was carried out at the Tribology/Materials Processing Laboratory at the Pennsylvania State University, using two sets of conditions. Post-test samples were analyzed using profilometry and SEM/EDS techniques to quantify the wear track volume and assess coating integrity. Based on the results from both test conditions, the five coatings were ranked in terms of their wear performance as follows: Siltride > RD13 ≈ Dursan > SL1000 > RD14. Siltride was found to be the most wear resistant coating of the five, and the wear rate of Siltride was about 40% of the uncoated stainless-steel surface under both testing conditions.

Applications Where More Resistant Coatings Would be Beneficial:

- Flow control valves in process analyzers

- Steel molds and extrusion components for plastics

- Heat exchanger tubing (size limitations apply)

- Mixers and reactors

- Pump components

- Threaded parts

- Cylinders, plungers, and impellers

If you are interested in learning more about our coatings and their properties, please contact us!

References

1) https://www.tribonet.org/wiki/pin-on-disk-test/

2) Novak, R. and Polcar, T. “Tribological analysis of thin films by pin-on-disc:evaluation of friction and wear measurement uncertainty”,Tribology International 2014, 74, 154.