Single-use systems (SUS) have become a staple in the life sciences sector. From simple laboratory workflows to large-scale processing, disposable components offer clear advantages: reduced cleaning, lower contamination risk, and faster turnaround. But there’s one often-overlooked concern - metal ion leaching from non-plastic process-contact surfaces like sensors, flow meters, and other pneumatic devices - that can compromise even the most carefully controlled systems. Not to mention, the wastefulness and ever-narrowing PFAS regulations.

A Hidden Source of Contamination

Even in systems marketed as “all plastic” or “disposable,” stainless steel and other metal components still play a supporting role. Sensors, connectors, flow restrictors, probes, and valves - many of these are made from metal and are exposed to process fluids, buffers, and reagents.

When exposed to harsh chemicals, sterilization steps, or even prolonged storage, these surfaces can leach trace metals like iron, nickel, or chromium into the surrounding environment. In many life science workflows, even trace contamination can:

- Interfere with sensitive assays

- Skew analytical results

- Impact sample integrity

- Affect reproducibility

Where It Shows Up

Metal leaching isn’t limited to bioprocessing. It can occur in many other analytical environments, such as:

- Laboratory sample prep and analysis

- Diagnostic instrument fluid paths

- Environmental and food testing labs

- Clinical research systems

The risk is especially high in low-concentration workflows where purity and consistency are critical. Ironically, the move toward faster, disposable systems may unintentionally reintroduce variables researchers are trying to eliminate. Read our previous blog on a real-world example from one of SilcoTek's own scientists.

How Inert Coatings Help

SilcoTek coatings provide a simple way to eliminate metal surface reactivity without replacing or redesigning existing parts. Our ultra-thin, inert coatings (like Dursan®) are applied via chemical vapor deposition (CVD) and create a barrier between metal surfaces and process fluids.

Benefits include:

- Reduced metal ion leaching, even under aggressive conditions

- Compatibility with acids, solvents, and sterilization processes (Check our Chemical Compatibility Chart)

- Improved chemical inertness and cleanliness

- Greater stability in storage and use

Our coatings are widely used in chromatography, diagnostics, research labs, and precision instrumentation.

Temperature Stability

While temperatures in BPE and pharma applications don't typically get too hot, the fact remains that plastics commonly used in SUSs can become permeable and delaminate under certain conditions. SilcoTek's surface treatments are stable up to 450°C, making them capable of a wider array of testing conditions.

Complying with Tightening PFAS Regulations

Perfluoroalkoxy alkane (PFA) - a common material used in SUSs - and other PFAS are frequently incorporated into biopharmaceutical processes due to their chemical resistance, non-wettability, and ability to modify surface properties of metals. However, the widespread use of these “forever chemicals” significantly increases the risk of contamination within critical process streams. In contrast, SilcoTek coatings are composed of naturally abundant elements such as silicon, oxygen, carbon, and hydrogen. They contain no fluorinated compounds, hazardous solvents, or materials requiring special handling or disposal. Importantly, SilcoTek coatings are engineered to be chemically inert - they do not degrade into harmful by-products or leach into the process environment. As global regulatory scrutiny of PFAS intensifies, adopting PFAS-free solutions like SilcoTek coatings can support compliance while maintaining high-performance standards in pharmaceutical and biopharmaceutical manufacturing. Here's a list of the current PFAS chemicals the US EPA is evaluating.

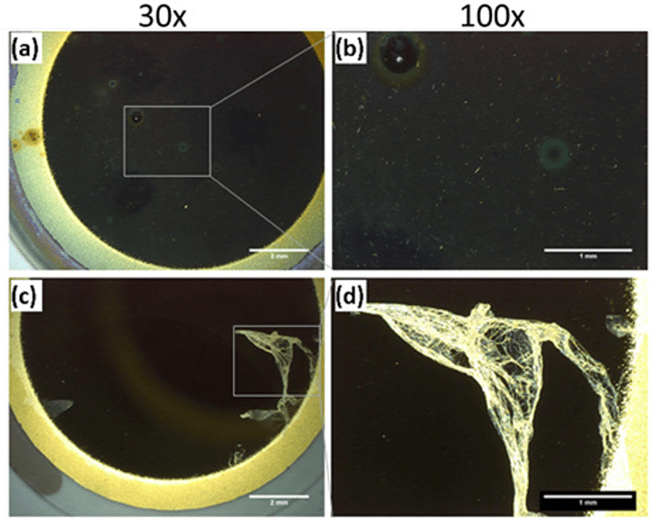

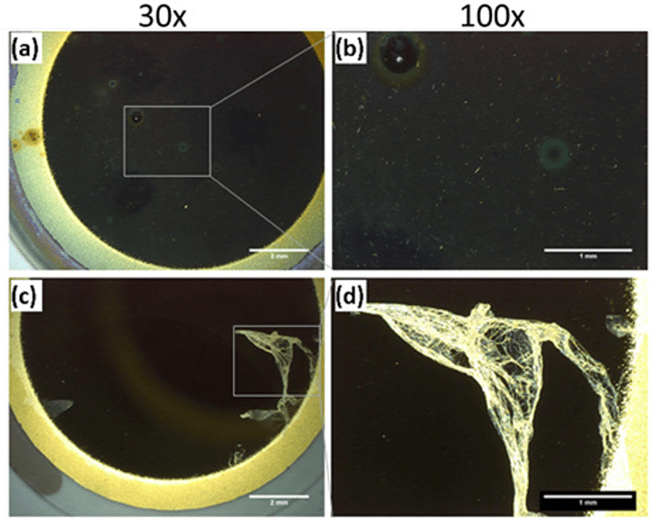

Here's a technical insight write-up we conducted with Abbott Laboratories on protein adsorption to surfaces using our Dursan coating. Below is a graphic depicting the delamination data comparing Dursan to AF1600 (a PFA, Teflon®). It shows an optical micrograph comparison of Dursan coating (a, b) and AF1600 coating (c, d) after cleaning and sonication treatment. Film delamination was observed in the AF1600 coating, while the Dursan coating remained intact. The PFA was damaged in routine cleaning and sterilization procedures that involve aggressive chemicals and sonication.

From a sustainability standpoint, we must also consider the environmental impact of single-use systems. Customers can get hundreds or even thousands of uses from one system without using PFAS on product-contact surfaces as well as dramatically decrease waste. There has been a global push for more sustainable practices across all industries and this is a great way to reduce your environmental footprint.

Smarter Single-Use Design

While plastic gets the spotlight in disposable system design, the small metal parts matter too. Coating metal surfaces ensures they’re as clean and inert as the polymers around them, helping to maintain the high standards expected in today’s life science workflows. Best practices for modern pharmaceutical equipment manufacturing incorporate both single-use components like polymers as well as stainless steel systems such as process instrumentation. Applying SilcoTek surface treatments to stainless steel and other metal surfaces essentially make them behave like glass, with none of the downsides of plastics described above such as permeation or potential PFAS exposure.

Want to Learn More?

If you’re using single-use systems in your lab or process and want to reduce trace contamination risk, contact our team today. We’ll help you evaluate which components may benefit from an inert coating and how to make your systems even cleaner.