In July, the International Conference on Environmental Systems presented a paper in which researchers have been looking into microbial control in wetted components of a Spacecraft Potable Water System (SPWS). They were looking for a practical and efficient multibarrier strategy for microbial control to protect the crew, minimize system maintenance, and reduce the risk of microbial fouling and corrosion. They tested a range of different substrates and surface treatments to determine which was the best for this application.

Among those were SilcoTek's own Dursan® and SilcoNert 2000® coatings.

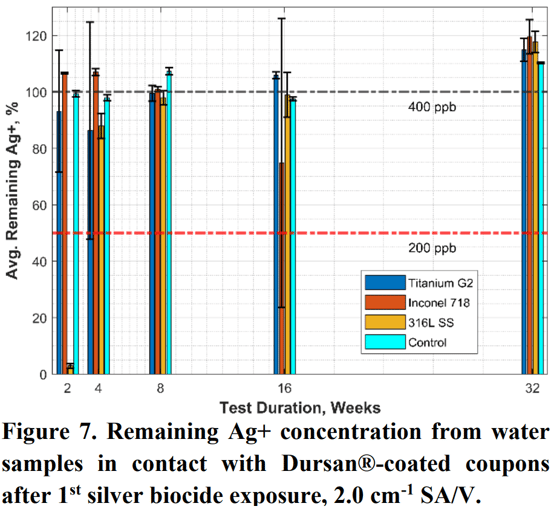

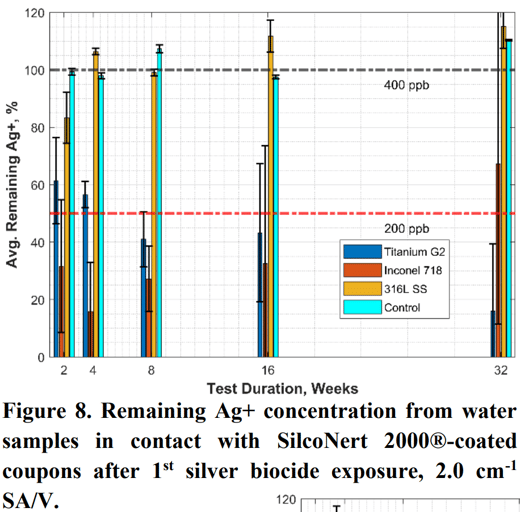

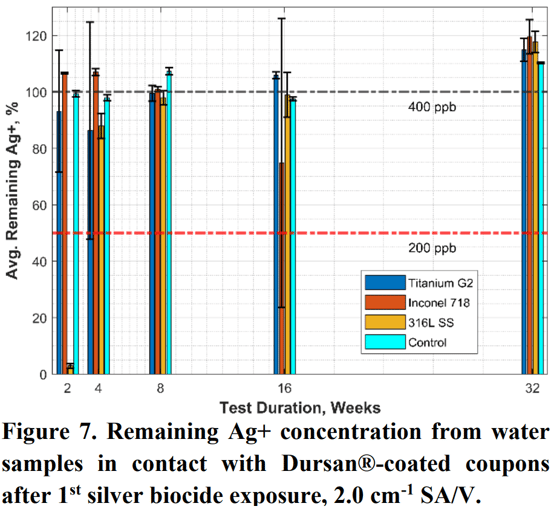

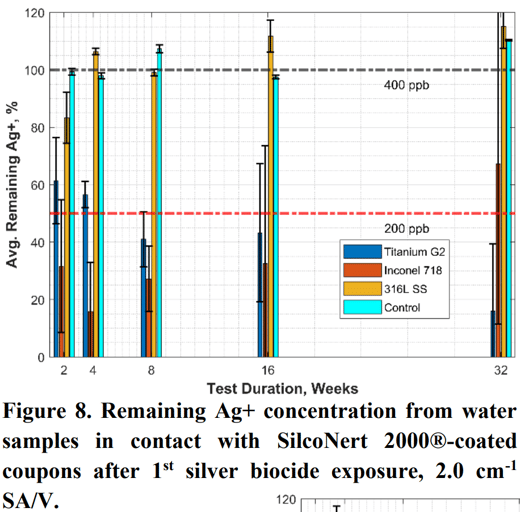

In this research, they investigated ionic silver as a common biocide for SPWS aboard different water system architectures. While ionic silver is harmless to human consumption, it can be detrimental to the wetted componentry of the SPWS. Unfortunately, "there is a propensity for the biocidal form of silver (Ag+) to be depleted from the liquid phase to a surface with Ag+ affinity. These losses can be accentuated in static water conditions and in geometries with large surface area to volume ratios (SA/V), namely small pipe sections, valves, and fittings." (Garcia Fernandez et all, 2023). Thus, began their research into how they could possibly solve this issue. They tested 3 different substrates (Titanium Grade 2, Inconel 718, and 316L Stainless Steel) as well as 11 different coatings to determine what percentage of Ag+ remained after predetermined intervals.

How Did SilcoTek Coatings Compare

Silcotek coatings, such as Dursan and SilcoTek 2000, are known for their inert, non-stick, and anti-corrosive properties, which can be advantageous for water systems, including the Spacecraft Potable Water System (SPWS). Here are some ways in which Silcotek coatings can help water systems:

-

Corrosion Resistance: Silcotek coatings provide excellent corrosion resistance. Water systems are susceptible to corrosion, which can affect the integrity of the system components and water quality. Silcotek coatings protect the metal surfaces from corrosion, extending the lifespan of system components.

-

Inert Surface: These coatings create an inert surface, reducing the potential for chemical reactions or interactions between the metal surfaces and the water. This will help maintain water purity and prevent the leaching of metals into the water, which is crucial for potable water systems.

-

Reduced Biofouling: Silcotek coatings have a non-stick property, which reduces the adherence of biofilms and microorganisms to the surfaces. In water systems, biofouling can lead to microbial contamination and decreased system efficiency. Silcotek coatings help to minimize biofouling, ensuring water quality and system performance.

-

Minimized Ag+ Depletion: The presentation mentions that some coatings, including Dursan and SilcoNert 2000, performed well in maintaining Ag+ (silver ion) levels in water systems. This is particularly important in space applications like the SPWS, where silver is used as a biocide. Silcotek coatings help to prevent the depletion of Ag+ and maintain its concentration, ensuring the effectiveness of silver-based biocides. The below graphs depict how Dursan and SilcoNert 2000 tested when exposed to Ag+ water samples for 2, 4, 8, 16, and 32 weeks.

-

Easy Cleaning: The non-stick property of Silcotek coatings makes it easier to clean and maintain the water system. Reduced adhesion of contaminants and impurities makes the cleaning process more efficient, reducing maintenance efforts.

-

Compatibility: Silcotek coatings are designed to be compatible with a wide range of metals and materials, making them versatile for various components within the water system. Dursan is NSF certified and FDA compliant, making it ideal for applications involving human consumption.

-

Longevity: By protecting metal surfaces from corrosion and degradation, Silcotek coatings extend the longevity of system components, reducing the need for frequent replacements or maintenance.

Commonly Coated Items in Water Systems

As noted, the wetted components of water systems can be coated to ensure the entire system is protected with a thin barrier coating. Here are some commonly coated items that are used in water systems:

- Metal Filtration Media

- Pumps

- Housings

- Piping

- Tubing

- Valves

- Fittings

- Tanks

- Vessels

Conclusion

Silcotek coatings, with their anti-corrosive, inert, and non-stick properties, are valuable for water systems by ensuring water purity, reducing biofouling, and maintaining the effectiveness of biocides like Ag+. Our coatings offer a practical solution to enhance the performance and longevity of water systems, including those used in space applications like the SPWS. While some alternative polymer coatings performed similarly in this study, those same coatings could become problematic as they contain PFAS (polyfluoroalkyl substances), which are under scrutiny by many government agencies due to their potentially harmful health effects in humans and animals.

If you would like to learn more information about SilcoTek's coatings and their capabilities, please reach out to our coating experts!

Reference:

Garcia Fernandez, R. E., Marshall, S., & Adam, N. (2023). Material Compatibility Study of Coated Metals to Maintain Biocidal Silver in a Spacecraft Potable Water System [Review of Material Compatibility Study of Coated Metals to Maintain Biocidal Silver in a Spacecraft Potable Water System]. In International Conference on Environmental Systems. https://www.researchgate.net/profile/Ro-Garcia-F/publication/374440901_Material_Compatibility_Study_of_Coated_Metals_to_Maintain_Biocidal_Silver_in_a_Spacecraft_Potable_Water_System/links/651d6facb0df2f20a2110288/Material-Compatibility-Study-of-Coated-Metals-to-Maintain-Biocidal-Silver-in-a-Spacecraft-Potable-Water-System.pdf