This week, we wanted to go through the process of an order from start to finish at SilcoTek. From your first inquiry to invoicing, there are step by step processes we go through to ensure you're getting the best coating possible.

At a high level overview, the process goes from sales to quotes to receiving to customer service and manufacturing to quality to shipping and then finally to finance. I'll explain each of those steps now.

The Step-by-Step Process

- Starting with sales, this is the beginning stage where our sales team members evaluate your application and determine the best coating(s) for you. At this step, we can send you a free sample or you can send us your own parts for a free or reduced price trial order. For some common applications, we can even point you in the direction of one of our approved partners for a faster lead time. Once you and sales decide what parts and coatings are right for you, our Quotes team will add an order to our system so it can easily be identified at receipt.

- Once received, your parts are inspected to ensure we got everything you sent. We also photograph the parts for verification and traceability. If there are any questions or "red flags" before coating, our customer service team will contact you to review your order and any potential concerns with processing. Once everything is confirmed, our customer service team sends you an order acknowledgment email with our ship by date.

SilcoTek takes special care to collaborate with all our customers and provide exceptional service that exceeds your expectations. Our manufacturing process is designed to expedite every order that we process. For those customers who are in a crunch and need faster turn around times, we offer a 2-tiered expedite program! Customers who need to expedite their lead time by 3-4 business days can take advantage of our expedite coating service. To improve lead times by 5 or more business days, customers can utilize our priority coating service. Please see the expedite PDF for the fee structure on expedited services. It is important to note that while we hope to accommodate every expedite and priority processing request to assist customers who require improved lead times, there will be times that we must decline due to high order volumes at our facility. It is critical to us that no customer who accommodates SilcoTek's standard coating process lead times ever experiences longer turnaround as a result of honoring expedite requests.

- For the third step in the process, SilcoTek uses proprietary surface preparation methods in order to ensure the best coating possible. It is important to know that any surface imperfections like scratches, rough surfaces, or widely varying surface characteristics, will be highlighted by the coating process, not hidden. That's why creating a pristine, contaminant free surface prior to coating is critical for optimal results and good visual appearance. To ensure the best coating possible, be sure to help us understand everything your parts have been exposed to prior to sending them to us for coating.

- Up next is the coating process. After a thorough surface preparation, our technicians load customer parts into a vacuum vessel corresponding to the size of the parts. This vessel is placed in a large oven and connected to the raw material, gas, then heated to coating temperatures. Throughout this process, a proprietary blend of gas enters the vessel and starts a reaction which diffuses the treatment into the molecular lattice of the substrate, forming the ultra-thin SilcoTek coating that so many have come to recognize and trust.

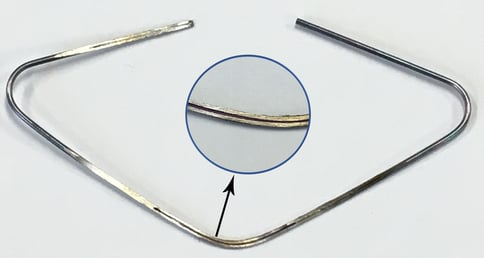

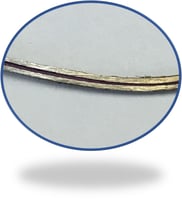

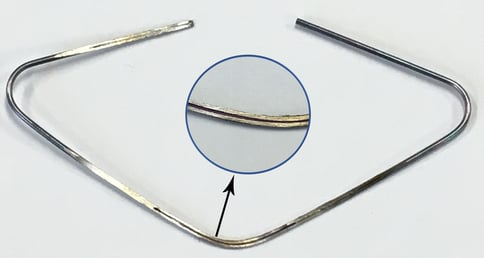

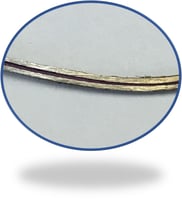

To illustrate this, we coated a 1/16" OD, .4mm ID tube with multiple bends both internally and externally. After coating, the tube was cut open to examine the coating at the center-most point inside the tube. In addition to the external coating on the tube, a quick visual inspection shows the vibrant purple-colored SilcoTek coating inside the narrow bore. The thickness of the coating throughout the tube was verified by a Filmetrics F40-Series Thin Film Analyzer and confirmed to meet our specifications. SilcoTek coatings are not applied with line-of-sight processes like spraying that lead to inconsistent deposition and uncoated areas. With our process, 100% of your parts are coated, even if the design is complex or the pathways are tortuous.

- Once the coating process is complete, your parts are unloaded and moved to the inspection area. SilcoTek technicians then visually inspect each part to ensure conformal thickness and proper aesthetics and then review coating run data to verify all process parameters meet specification. Parts that pass inspection are issued a coating certification adherent to ISO 9001.

- After the parts have passed inspection, we package them so that they are secure and won't be damaged when traveling to the field, plant or back to the factory. Customer packaging is only re-used for return shipping upon request. If, at receipt, incoming packaging is deemed inadequate for secure shipping, SilcoTek will use new packaging to ensure coated parts are returned safely. If shipping out of the United States, our international customer support specialist will work closely with you to arrange logistics efficiently.

Once the parts are ready to go, we send you an email to confirm that they are shipping by your preferred method. They're now coated, to specifications, and ready to make what was impossible possible! We also have a video detailing these steps.

And that is the step-by-step process! If you ever have any questions, please don't hesitate to reach out to our coating experts. We're always here to help.