Not all stainless is created equally. Selecting the best stainless steel for the application is essential for improved corrosion resistance, even if the stainless has a corrosion resistant coating.

What's the Best Stainless Steel for a Corrosion Resistant Coating

Corrosion and Stainless Steel Background:

304 and 316 stainless steel substrates are among the most commonly used grades of stainless steel materials in many industries. The key difference between these two grades is the addition of 2~3% of molybdenum (Mo) to the 316 family of stainless steels. This addition drastically enhances the corrosion and oxidation resistance of the alloy, especially for environments exposed to saline or chloride-containing chemicals.

|

In this blog post you will learn:

- How comparing the corrosion resistance of 316 stainless steel and 304 ss in various corrosion applications can help optimize coating performance.

- How different CVD coatings perform under highly corrosive conditions.

- How the type of stainless steel substrate can impact the corrosion performance of silicon CVD coatings.

- How considering the combination of the baseline metal and the coating as a whole will optimize corrosion performance.

|

When considering corrosion applications, the right choice of metal material makes a world of difference. This is true even when a corrosion-barrier coating, such as the CVD coatings offered by SilcoTek, is deposited on top of the metal. A protective coating provides a barrier between the metal and the surrounding corrosive environment, so that instead of directly interacting with the metal, the corrosive chemicals will have to diffuse through the pathways within the coating (i.e. cracks, pinholes, capillaries, microscopic pores, and defects inherent in almost any coating system) to eventually reach the metal and initiate a corrosion reaction.

Superior coating systems have fewer diffusive pathways, both in terms of quantity and size, and the corrosive species take longer to penetrate through the coating to reach the substrate. Thus a good protective coating can significantly extend the useful lifetime of a metallic part. The corrosion rate of a coated metal part can be considered as a percentage of the corrosion rate of the bare metal (e.g. 1%, 10% etc. depending on the quality of the coating itself and the quality of the base metal and coating interface). Therefore, when compared to a lower grade counterpart, a better metal substrate will always provide a better baseline, which translates to a lower overall corrosion rate when coated.

This blog compares the performance of 304 and 316L stainless steel coupons, both coated with SilcoTek’s Dursan coating, in hydrochloric acid and sulfuric acid solutions over the period of one week. The results indicate that the choice of the substrate metal should be commensurate with the severity of the corrosive environment, even in the presence of a coating. In harsh HCl and H2SO4 applications, 304 SS should be replaced with coated versions of 316 SS or other higher grade alloys for better anti-corrosive performance.

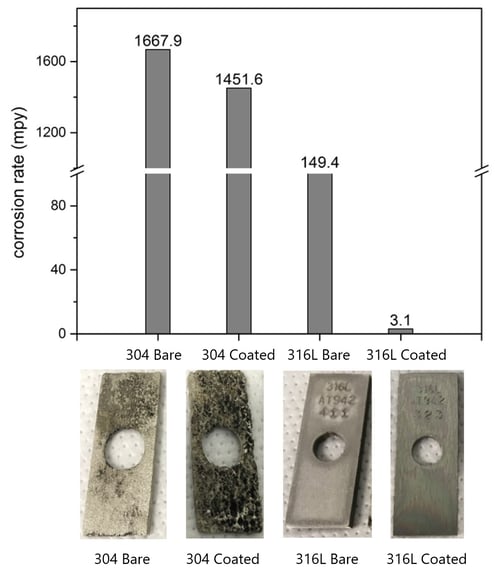

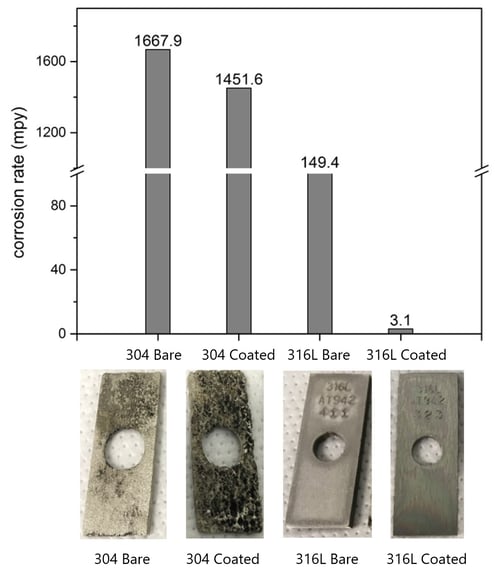

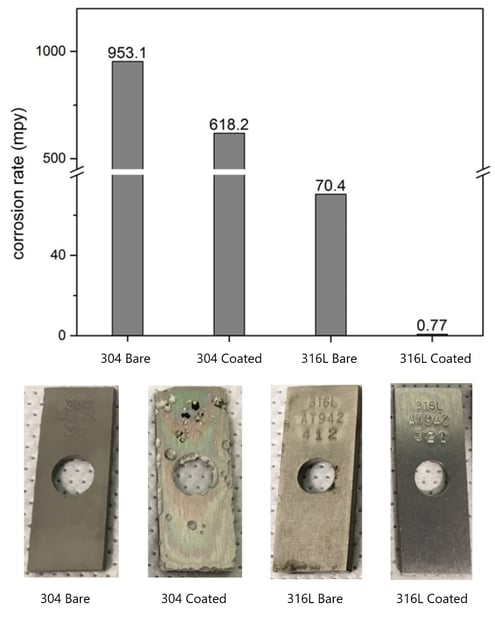

The first test was performed by immersing the test coupons in 6M hydrochloric acid, HCl (about 20 wt%) for one week at room temperature. Coupons tested include uncoated 304 and 316L SS (argon anneal passivated), along with coated 304 and 316L SS (argon anneal passivated and Dursan-coated). The calculated corrosion rates after one week of immersion, as well as the photos of representative coupons, are shown in Figure 1 below. Clearly the 304 SS coupons, even coated, did not hold up well against this exposure, as severe corrosion was observed on all 304 coupons. The coating only provided a moderate corrosion rate reduction of 13%. The Dursan-coated 316L SS, on the other hand, demonstrated that with a superior base metal, the benefit of the coating is maximized, showing an improvement factor of over 60 fold.

Figure 1) Corrosion test results of 304 and 316L SS coupons in 6M HCl for one week

What’s noteworthy is that the disparity between the two grades of substrates is substantially magnified by the presence of the Dursan coating, i.e. the corrosion rate of the bare 316 was about 10 times lower than that of the bare 304, whereas the corrosion rate of the coated 316 was about 500 times lower than that of the coated 304. Why?

One possible explanation is that the addition of Mo to the 316 grade not only serves to improve the bulk metal’s corrosion resistance, but also plays a beneficial role in the passivation process of the stainless steel (both the 304 and 316 SS samples were anneal passivated before coating). Literature reports indicate that Mo works synergistically with Cr to facilitate the formation of a higher quality Cr enriched passive film on the surface, and the multi-valent molybdates also help to reduce defects within the passive film.1-4 A better passive film on the metal surface for the coating to initially deposit onto means a stronger coating/substrate interface. A stronger interface helps to form a denser coating seed layer, which in turn grows into an overall higher quality coating. The combination of a stronger foundation and a better bulk film equals less diffusion pathways for the corrosive species, and ultimately lower corrosion rate and better corrosion resistance.

304 SS, on the contrary, does not enjoy such beneficial “chain effects” induced by Mo. The concentrated chloride ions therefore had an easier time to diffuse through the coating on 304 SS, in order to initiate a corrosion reaction with the metal. Once the reaction started, it would proceed much faster with 304 than with 316 SS, as 304 is a less corrosion-resistant metal itself. This leads to quicker compromises of adjacent sites, and more subsequent penetrations at the interface to allow corrosive attacks on the metal. The inferior metal substrate itself combined with a more permeable coating led to an “avalanche” effect that saw the quick destruction of the metal/coating bonding interface and eventually the severe corrosion of the metal itself.

Want to test the performance of our coatings in your application? Get a free coating sample.

The Second Corrosion Test

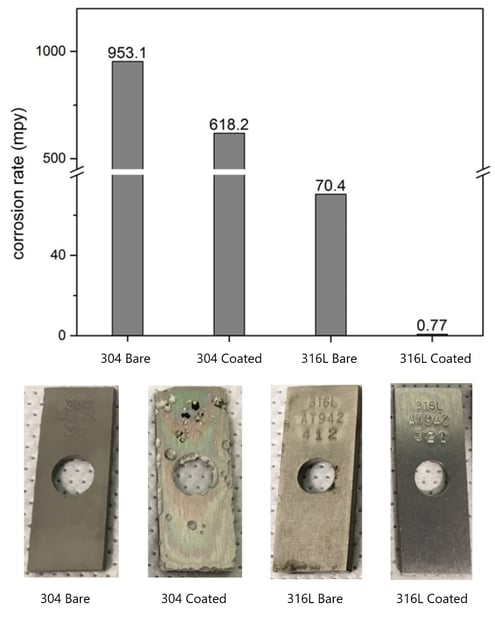

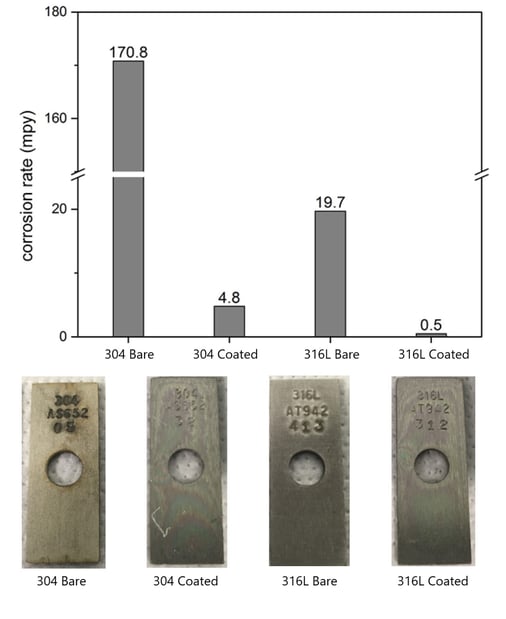

The second test was performed by immersing the test coupons in 25 vol% sulfuric acid, H2SO4 (38 wt%) for one week at room temperature. The coupon experimental design was the same as in the first test, with the exception that the bare coupons were not argon annealed. The calculated corrosion rates after one week of immersion, as well as the photos of representative coupons, are shown in Figure 2 below. The results were similar to what was observed in the first test. The 304 SS, being a poor baseline material for this exposure condition, underwent heavy corrosion with or without the Dursan coating. The uncoated sample exhibited a uniform corrosion whereas the coated sample showed mostly pitting corrosion, especially along the edges and around the sample label stamps. These regions are likely “weak links” due to the fact that they are metallurgically more stressed, therefore are more prone to local coating failures and corrosive attacks. The 316L SS substrate material, as seen in the HCl test, fared a lot better. The Dursan coating effectively reduced the corrosion rate by two orders of magnitude when applied on the 316 grade stainless steel, a significantly greater benefit than on its 304 counterpart in the same harsh exposure environment.

Figure 2) Corrosion test results of 304 and 316L SS coupons in 25% H2SO4 for one week

For Best Results Match the Stainless Steel Alloy to Your Application.

It should be made clear that these data do not suggest that the Dursan coating offers no help for 304 SS in all corrosion applications. Instead the data emphasizes the importance of starting with an appropriate substrate metal according to the harshness of the exposure. In a less aggressive corrosion application, such as a less concentrated acid environment, Dursan offers significant protection and lifetime extension to 304 SS (and 316 SS) base materials.

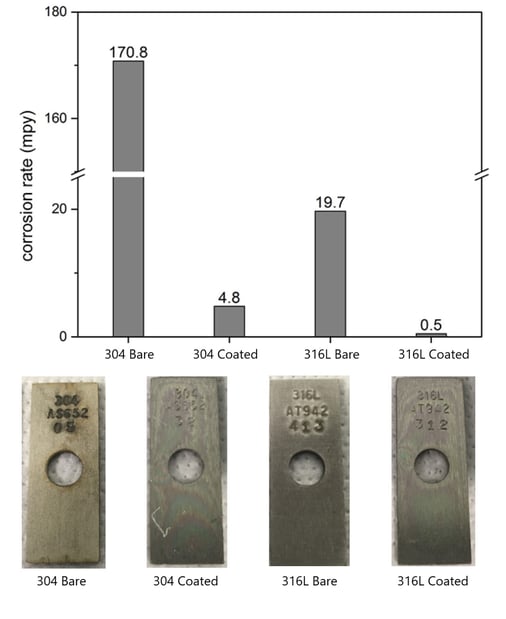

Figure 3 below shows the corrosion rates and corresponding photos of coated vs. uncoated 304 and 316L SS coupons after one week of immersion in 5% hydrochloric acid, HCl, at room temperature. The coupon experimental design was the same as the second test above. This is a much milder corrosive environment than the 20% HCl test in Figure 1, and the Dursan coating has effectively reduced the corrosion rates of both the 304 and 316 SS, by about the same rate.

Figure 3) Corrosion test results of 304 and 316L SS coupons in 5% HCl for one week

Conclusion:

Collectively, these results suggest that the best route to tackle a corrosion challenge with SilcoTek’s CVD coating is to consider the combination of the baseline metal and the coating as a whole, and test the combination out in the intended corrosive environment. The same coating that works on one base metal material does not necessarily perform equally on a different grade of material in the same application. The severity of the environment, the quality of the substrate metal, the interface between the coating and the substrate metal, the quality of the coating itself, and the expectations of the end user (i.e. expected lifetime and allowable material loss, etc.), all play a role and combined together, determines whether a solution is successful for a particular corrosion challenge or not.

This blog examined the corrosion performance of 304 and 316L SS coupons, when coated with SilcoTek’s Dursan coating vs. uncoated, in a series of acidic exposures. It was found that in more severe exposures (i.e. immersion in 20% hydrochloric acid, HCl, or 25% sulfuric acid, H2SO4, for one week), the 304 SS material does not hold up well regardless of having a Dursan coating or not. On the other hand, the 316L SS saw great benefits from the Dursan coating in these harsh environments. In a less severe exposure (i.e. immersion in 5% HCl for one week), both the 304 and 316 grade SS saw significant improvements with the Dursan coating.

These results suggest that the best route to tackle a corrosion challenge with SilcoTek’s CVD coating is to consider the combination of the baseline metal and the coating as a whole, rather than just picking a coating and applying it to any baseline metal. The severity of the environment, the quality of the substrate metal, the interface between the coating and the substrate metal, the quality of the coating itself, and the expectations of the end user (i.e. expected lifetime and allowable material loss, etc.), all play a role and combined together, determines whether a solution is successful for a particular corrosion challenge or not. Therefore, we recommend customers to test the combination in the actual application environment for validation before making a decision and scaling up.

Want to purchase SilcoTek coated products directly from the manufacturer? Go to our Products and Partners page by clicking the image below and click on your application or desired vendor.

Reference:

- Sakashita, M. and Sato, N. “The effect of molybdate anion on the ion-selectivity of hydrous ferric oxide films in chloride solutions” Corrosion Science 1977, 17, 473-486.

- Lu, Y.C., Clayton, C. R., and Brooks, A. R. “A bipolar model of the passivity of stainless steels – II. the influence of aqueous molybdate” Corrosion Science 1989, 29, 863-880.

- Jargelius-Pettersson, R. F. A. and Pound, B. G. “Examination of the role of molybdenum in passivation of stainless steels using AC impedance spectroscopy” 1998, 145, 1462-1469.

- Fredriksson, W. “Depth profiling of the passive layer on stainless steel using photoelectron spectroscopy” Uppsala Universitet 2012 PhD dissertation.