Process analytical technology (PAT) has been evolving and improving pharmaceutical processes for years. FDA guidelines highlight design, manufacturing, and quality systems that contribute to improved control of production processes. The guidelines may focus on pharma, but the fundamentals can be applied to any process that requires sampling and control; including environmental sampling, laboratory, refinery or chemical process industries.

The guidelines touch on the basic building blocks of good process analytical management such as:

A well thought out analytical and process control system that designs quality into the process from the start will save the plant operators in the not-so-long run. Quality designed in from the start encompasses all factors from material selection, system design/layout, component selection, installation, and data management.

Material selection

Good sample transport system design incorporates multiple factors in material selection including corrosion resistance, surface inertness/adsorption, functionality, workability, durability, and cost. Stainless steel is the go to material for sampling transport systems because it checks most but not all of the design boxes. Under extreme conditions stainless steel can corrode and adsorb test analyte, causing inertness issues and premature system failure.

Inert coatings are used as a backstop to stainless steel's weak points. The result? Improved process measurement quality and durability. Start by selecting the right coating for the application. Select the coating based on:

- System exposure/environment

- Target performance (ie. corrosion, ppm or ppb inertness, etc.)

- Cleaning method/exposure to cleaners

- Analyte

- Maintainability

- Expected life of the sample system

Use our quick guide to help select the right coating material for the application.

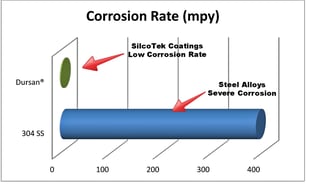

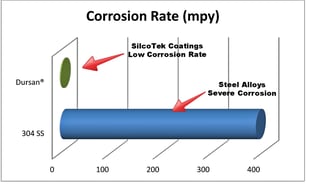

Manage corrosion

To assure corrosion resistance and inertness coat analytical flowpaths with inert materials that will not interact with analyte or cleaning materials and will act as a barrier to corrosive effects. Comparative immersion tests of Dursan® and stainless steel in 6M hydrochloric acid demonstrate the high corrosion potential of stainless steel.

Corroded stainless steel surfaces can produce adsorptive particulates as well as damage system operating integrity, inert coatings like Dursan coated flowpaths prevent corrosive attack by orders of magnitude.

Manage inertness

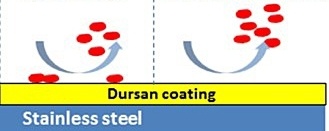

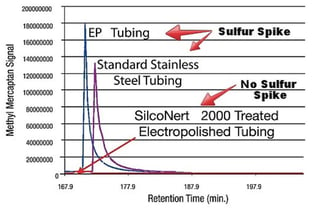

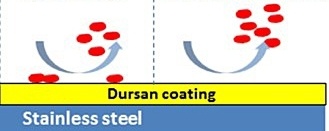

Sticky compounds like H2S, mercaptans, even protein molecules can adhere or be adsorbed by stainless steel. Even in high veloscity flowpaths, compounds can stick to the surface; causing inaccurate results. Inert coatings like Dursan® and SilcoNert® prevent surface interaction with stainless steel allowing all the sample to reach the analytical instrument.

|

|

|

| Compounds can stick to stainless steel flowpaths even in high veloscity flowpaths. |

Dursan coated flowpaths prevent adsorption and sticking; offering part-per-million inertness even under extreme conditions. |

Manage adsorption/desorption effects

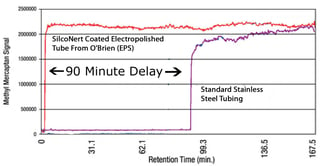

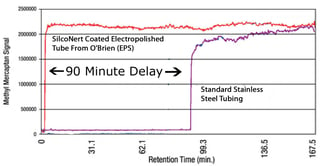

Adsorption and subsequent release of active compounds in the sample transport system can severely distort analyzer results. Failure to manage adsorption can cause seemingly random spikes and dips in analyzer readings. Sample flow through uncoated stainless steel tubing can result in delays in response or false negative results. Delays of 90 minutes or more can result from adsorption of the sample.

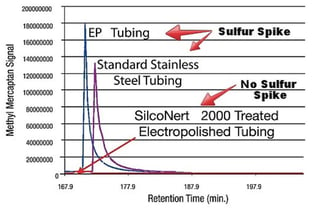

After the delay in response, sulfur and other sticky compounds can desorb or release from the surface; causing spikes in analyzer readings.*

Design factors For Improved Process Analytical Performance

A recent paper by Phil Harris, Haritek, and O'Brien Analytical highlight how common sample transport design issues could distort analytical results. More importantly the paper recommends ways to improve sample system reliability.

Here are tips on how to improve sample system reliability.

Robust sample transport design

The Harris study notes key factors when specifying the sample flowpath. Factors to consider are:

- Species to be analyzed,

- Sample gas composition and dew point / phase behavior,

- Length of the sample line run,

- Operating pressure and temperatures,

- Required gas velocities and response times

- Material compatibility.

Proper flowpath design will avoid common sampling system failures like:

- False analyzer readings

- Slow calibration or inability to calibrate system

- Variable readings

- No results, then spikes in readings

- Frequent maintenance and component replacement

- Poor system durability and wear resistance

Manage moisture

Adsorptive water molecules can bond to stainless steel surfaces, especially oxidized stainless steel. An inert hydrophobic surface like Dursan® will repel moisture and prevent water from adsorbing analytes.

Product component selection and minimizing variability

Understand system component functionality and performance thoroughly. Is that cheap regulator made with low quality stainless steel? What is the optimum performance envelop of the component. Can the plant maintenance and engineering staff install and maintain the component? Can the component be installed properly in a repeatable fashion? These questions apply to complex continuous emission monitors but also to seemingly simple components like fittings or tubing. A sample transport system is only as effective as it's weakest link. A single adsorptive fitting or filter can impact system performance for years if not properly identified and controlled.

Build Quality Into The Process: Coat the entire sample flowpath

Coat all surfaces with an inert coating like SilcoNert® or Dursan® to prevent common sample transport issues like corrosion, adsorption, moisture contamination and slow response. Coat the following flowpath components:

|

|

Filters

Regulators

Tubing

Valves

|

Fittings

Sample Cylinders

Dip Tubes

Probes

|

It's easy to buy inert coated sample system components, just ask your supplier or go to our Buy Coated Products page to learn more. Building quality in to your process analytical system has never been easier!

*Data courtesy of Shell Research and Technology Centre, Amsterdam and O'Brien Analytical