We take an in-depth look into solving process sampling problems by focusing on the 3 Ms of sampling. What are the 3 Ms you ask?

OK I'll tell you what the 3 Ms are straight away and save you the pain of anticipation. The 3 Ms are:

Materials

Manage

Maintenance

Let's take a closer look at each of the M's and I'll explain why each are important.

|

In this blog post you will learn:

- How to improve air quality measurement and process control through material selection.

- How managing 3 key aspects of the sampling flow path can improve results and prevent failures

- How a few simple maintenance tips can go a long way to preventing failures and save money.

|

Materials

Material selection can be as easy as pulling whatever tube is available from the stock room but is seldom that easy. Good sample transport system design incorporates multiple factors in material selection including corrosion resistance, surface inertness/adsorption, functionality, workability, durability, and cost. The materials you use in the sample flow path must address all factors and requirements of the sample system.

Selecting compatible materials can avoid sample system failures such as:

- False analyser readings

- Slow calibration or inability to calibrate system

- Variable readings

- No results, then spikes in readings

- Frequent maintenance and component replacement

- Poor system durability and wear resistance

Stainless steel is the go-to material for sampling transport systems because it checks most - but not all - of the design boxes. Under extreme conditions, stainless steel can corrode and adsorb test analytes, causing inertness issues and premature system failure. Inert materials, like silicon coatings, are used as a backstop to stainless steel’s weak points. The result? Improved process measurement quality and durability. Start the process by selecting the right inert material, or coating, for the application.

Stainless steel is the go-to material for sampling transport systems because it checks most - but not all - of the design boxes. Under extreme conditions, stainless steel can corrode and adsorb test analytes, causing inertness issues and premature system failure. Inert materials, like silicon coatings, are used as a backstop to stainless steel’s weak points. The result? Improved process measurement quality and durability. Start the process by selecting the right inert material, or coating, for the application.

Select inert materials based on:

- System exposure/environment

- Target performance (i.e. corrosion, ppm or ppb inertness, etc.)

- Cleaning method/exposure to cleaners

- Analyte

- Maintainability

- Expected life of the sample system

Manage Corrosion, Inertness and Design

Manage Corrosion to assure the sample flow path does not become contaminated or damaged by corrosion. A corrosion free flow path assures non reactivity by preventing particulate generation and adsorption. Coat analytical flow paths with inert materials that will not interact with analytes or cleaning materials and will act as a barrier to corrosive effects.

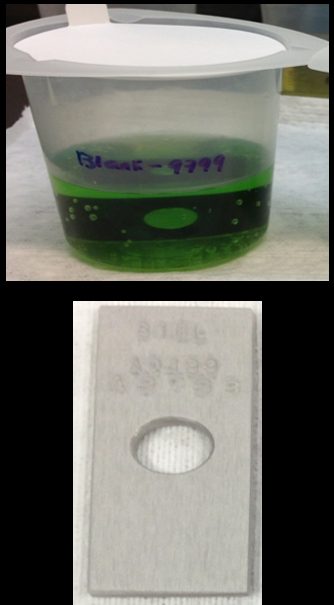

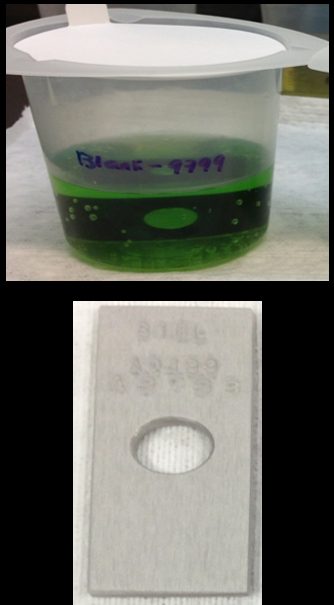

For example, comparative immersion tests of an inert silicon coating, Dursan®, and an uncoated stainless steel test coupon in 10% (vol.) hydrochloric acid demonstrate the high corrosion potential of stainless steel. The beaker and test coupon (below left) show green metal ion contamination of the acid solution and pitting of the coupon surface. The Dursan coupon shows little corrosion while the acid beaker remains free of contamination.

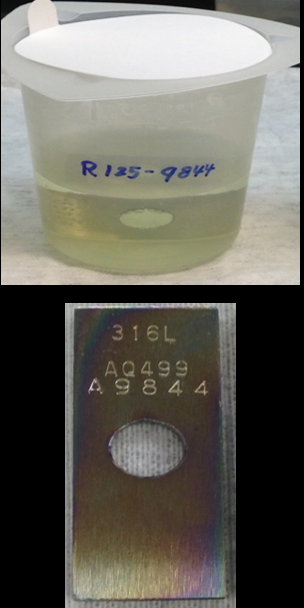

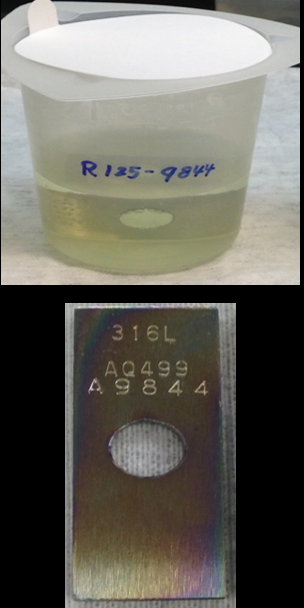

Corroded stainless steel surfaces can produce adsorptive particulates and can impact system operating integrity. Robust coatings like Dursan prevent corrosive attack by orders of magnitude. For example, sulfuric acid comparative tests (below) show the Dursan coated coupon improves corrosion resistance by roughly 90%. Good material selection can have a big impact on system durability, operating cost, safety, and test quality.

Manage Inertness

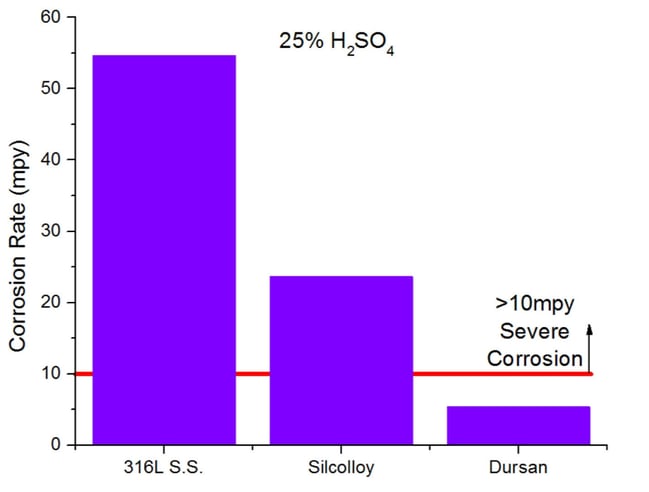

Sticky compounds like H2S, mercaptans, even protein molecules can adhere to or be adsorbed by stainless steel. Even in high velocity flow paths, compounds can stick to the surface and cause inaccurate results. Inert coatings like Dursan® and SilcoNert® prevent surface interaction with stainless steel allowing all the sample to reach the analytical instrument.

Adsorption/Desorption Effects

Adsorption and subsequent release of active compounds in the sample transport system can severely distort analyser results. Failure to manage adsorption can cause seemingly random spikes and dips in analyser readings. Sample flow path adsorption can result in delays in response or false negative results. Delays of 90 minutes or more can result from adsorption of the sample. After the delay in response, sulfur and other sticky compounds can desorb or release from the surface; causing spikes in analyser readings.

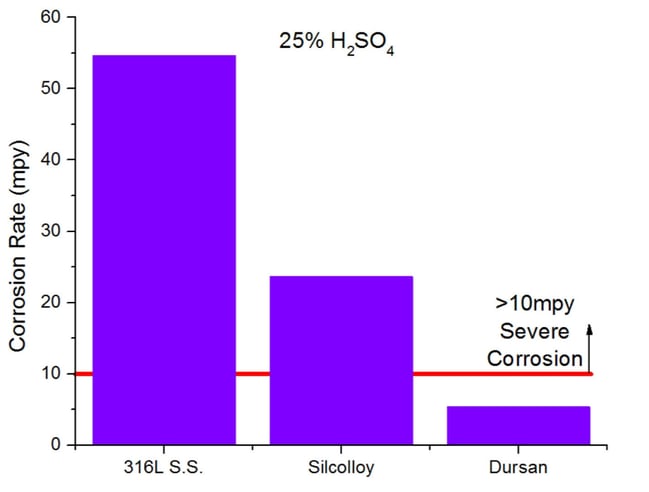

Comparative testing of aluminum, PTFE, Dursan®, SilcoNert®, gold and stainless steel exemplifies the difference an inert, non reactive surface can make on overall test performance. The uncoated stainless steel surface showed zero response (complete adsorption) of the sample even after 15 minutes of exposure. The SilcoNert coated surface showed consistent results and near immediate response with little adsorption.

Design Factors For Improved Process Analytical Performance

A recent paper by Phil Harris, Haritek, and O’Brien Analytical highlight how common sample transport design issues can distort analytical results. More importantly, the paper recommends ways to improve sample system reliability.

The Harris study notes key factors when specifying the sample flow path. Factors to consider are:

- Species to be analysed,

- Sample gas composition and dew point / phase behavior,

- Length of the sample line run,

- Operating pressure and temperatures,

- Required gas velocities and response times

Read the complete report for an in-depth analysis of key factors to consider when specifying sampling materials.

Maintenance

Following a maintenance plan can be major contributing factor to getting reliable process sampling test results and consequently maintaining process yield or regulatory compliance. Maintenance can entail complex test and validation programs but can also include some pretty basic hands on techniques that don't require much skill, only observation and some organization.

Some easy maintenance tips are;

- Visually inspect for corrosion by looking for rust stains. Disassemble sample cylinders or sample flow paths to inspect internal components.

- Inspect for leaks. Look for tell tale signs of leaks like drip stains or unusual odors.

- Observe wear points. Check for trace metal shavings or areas of metal-to-metal wear.

- Look for worn seals & gaskets. When inspecting for corrosion, check gaskets and seals for wear. Replace gaskets whenever disassembling a system.

- Check for delamination of PTFE coated components. PTFE coatings can delaminate from surfaces compromising test results.

- Inspect SilcoTek® coated components for damage or wear. It's easy to tell if a coated surface is being eroded or compromised, the rainbow color will begin to change or will be lost entirely. Get our Recommended Care Guide and read about some easy ways to maintain coated surfaces.

- Document inspections and key component age and use. Things don't last forever.

Hopefully I've at least sparked some thought regarding key factors to consider when designing for and solving process sampling problems. There are no doubt other key areas to consider but the Ms will get you started on the track to error free, low cost process sampling.

Want to learn more about maintaining an inert flow path surface? Get our surface care webinar.

Stainless steel is the go-to material for sampling transport systems because it checks most - but not all - of the design boxes. Under extreme conditions, stainless steel can corrode and adsorb test analytes, causing inertness issues and premature system failure. Inert materials, like silicon coatings, are used as a backstop to stainless steel’s weak points. The result? Improved process measurement quality and durability. Start the process by selecting the right inert material, or coating, for the application.

Stainless steel is the go-to material for sampling transport systems because it checks most - but not all - of the design boxes. Under extreme conditions, stainless steel can corrode and adsorb test analytes, causing inertness issues and premature system failure. Inert materials, like silicon coatings, are used as a backstop to stainless steel’s weak points. The result? Improved process measurement quality and durability. Start the process by selecting the right inert material, or coating, for the application.