Is Dursan® an HPLC coating? We tested our plastic free and metal free coating. Here's what we found out.

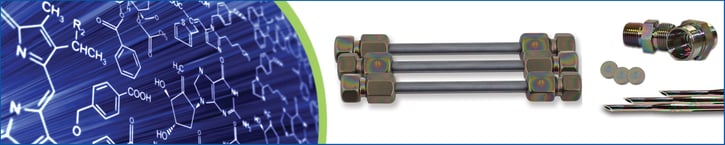

A bio-inert flow path is required to manage the complex and reactive sample profiles that are common in today’s fast-paced analytical world. Modern LC systems feature an array of exotic materials to achieve bio-inertness, but they are significantly more expensive than instruments constructed with stainless steel flow path components. Dursan® is a metal free and plastic free coating for stainless steel that provides equal or better inertness than PEEK along with improved durability. Dursan® is a simple and cost-effective solution for parts requiring inert properties throughout the lab.

|

In this blog post you will learn how Dursan CVD coating improves the bio-inertness and durability of HPLC flow paths.

- Creates a metal free HPLC flow path to minimize unwanted protein interactions and maximize uptime.

- Increases system robustness under extreme salt and pH conditions

- Improves bio-inertness of frits and other difficult components that cannot be treated by other methods

- Enhances chemical compatibility, even with media like tetrahydrofuran (THF) that challenge PEEK

|

Get the Liquid Chromatography Solutions Guide

Is Dursan® Metal Free?

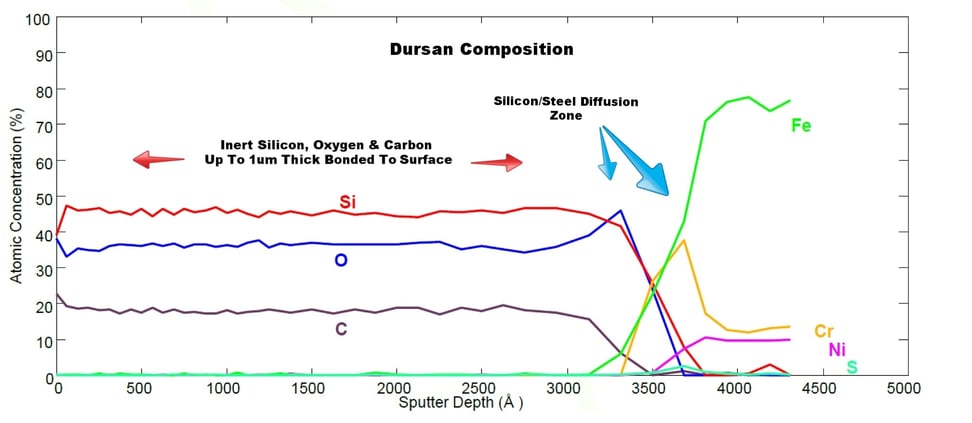

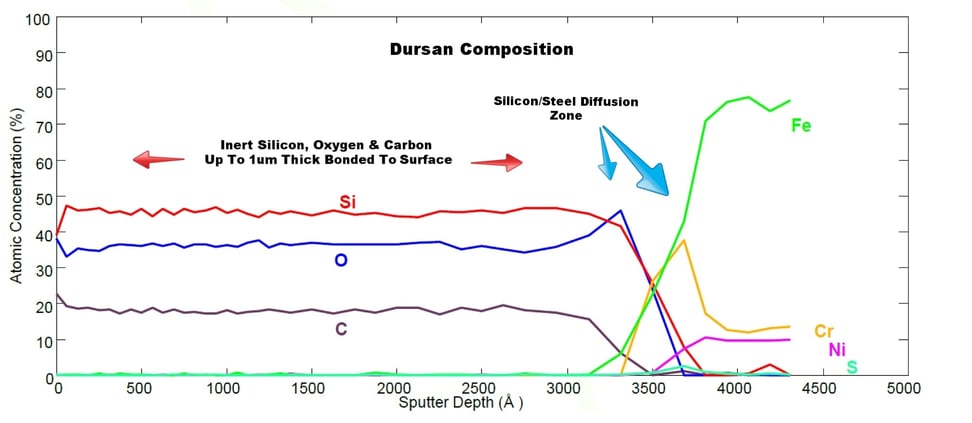

Auger spectroscopy testing (AES) tells the story. As the Auger electron beam sputters into the Dursan surface, detectors analyze the elemental make up of the materials coming off the surface. The detectors indicate a coating made up of silicon, oxygen and carbon with a roughly 500 angstrom coating/steel diffusion zone and no metals in the coating. That's good news for applications sensitive to exposure to metals and plastics.

Because Dursan is applied by chemical vapor deposition, the process gas can penetrate small bore, and even metal fritted filters to make virtually the entire HPLC analytical flow path metal free and inert.

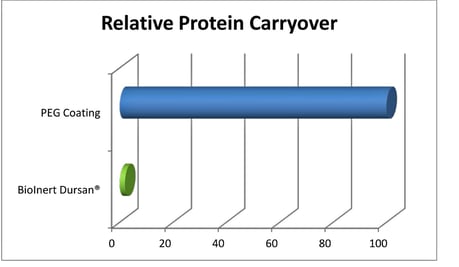

Is Dursan® a bio-inert coating?

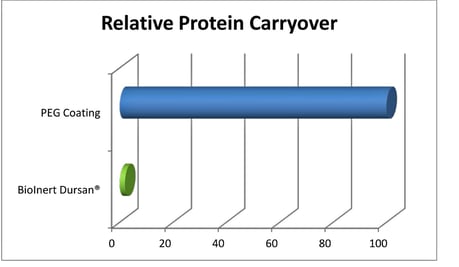

Comparative testing shows a significant reduction in protein carryover compared to PEG coatings. Fewer protein molecules stick to a silicon surface and those that do are easily washed away with a surfactant. In fact Abbott Labs recently completed a study of the surface. Read the paper here.

Comparative testing shows a significant reduction in protein carryover compared to PEG coatings. Fewer protein molecules stick to a silicon surface and those that do are easily washed away with a surfactant. In fact Abbott Labs recently completed a study of the surface. Read the paper here.

Because Dursan is applied by precision chemical vapor deposition, the entire HPLC flow path can be coated, including metal frits and the inner bore of needles.

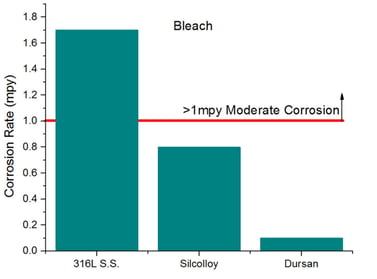

Is Dursan® a corrosion resistant HPLC coating?

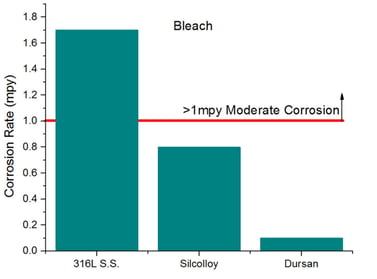

Under extreme chloride and bleach exposure, the silicon CVD coating performed exceptionally well with a orders of magnitude improvement in corrosion resistance.

Here's a photo of coated (left) and uncoated (right) coupons as they were being removed from our salt spray tank after 8000 hours of exposure. No rust on the coated stainless steel coupon but severe corrosion on the stainless steel coupons.

Bleach exposure tells a similar story. The uncoated stainless steel coupon showed severe corrosion after 72 hour immersion in 15% bleach. The Dursan coated coupon reduced the corrosion rate by over 90% all without exposure to metals or plastics.

What about compatibility?

Dursan's resistance to a wide range of acids and bases along with virtually no interaction with solvents make the carbon, oxygen, silicon surface ideal for HPLC applications. Get our compatibility summary or if you don't see a compound you're interested in, contact our technical service team.

Comparative testing shows a significant

Comparative testing shows a significant