So you're the proud owner of a super inert SilcoTek® coating like SilcoNert® or Dursan®. Now what? Ignore proper coating care and coating performance and durability will suffer.

The care and feeding of a coating is probably the most important factor in determining if the surface will continue to deliver high purity, corrosion resistance, or inertness over the life of the project or process. Follow a few simple maintenance tips and your inert surface will continue to deliver peak performance. You'll also find that living with an inert silicon coating is easy and profitable!

|

In this blog post you will learn:

- How to clean silicon CVD coatings.

- How to prevent damage to coating surfaces

- Steps to take in order to maintain coating performance throughout the life of the product.

|

Keep it clean

Maintain surface cleanliness to prevent cross contamination and accumulation of reactive particulates. Clean surface using the best minimally invasive method. Highly abrasive or basic (pH above 8) cleaners will damage the surface. We recommend using a non polar solvent like a high purity hexane to remove hydrocarbon contaminants, and a polar solvent to remove more active compounds. Get the highest purity solvent available, lower grades will leave a film on the surface. Get latest our latest presentation on how to maintain analytical flow paths.

Remember once you've cleaned and rinsed the surface, trace remnants of the solvent may cling to the surface. We've found many solvents can leave trace amounts of adsorptive or reactive substances on coating surfaces. Always test cleaning solvents for inertness and contamination before use in high purity or analytical applications. Using a coated HPLC column? We've got some tips on how to keep columns running at peak performance.

Don't get steamed

Refiners use steam to clean or purge sample transport flowpaths; however, live steam can cause silicon surfaces to become active. Live steam can also deliver particulates at high velocity to the surface, damaging the coating. As an alternative, consider sonication of components for a short duration or flushing the system with a solvent. (Note: Sonication can also damage the coating surface; avoid leaving parts in ultrasonic cleaners for more than a few minutes.)

Don't exceed the pH range

Exposure to bases above a pH of 8 can erode the silicon surface. One way to tell if the surface is being eroded is to check the color of the part. If you notice the iridescent rainbow coating color changing, it's a good indicator the coating becoming thinner and is being damaged. To stop further coating damage, flush the exposed surface with a neutral liquid, like water, or whatever neutral solvent that is compatible with your system. Want to learn more about coating compatibility? We've got a handy quick reference guide to help users understand our coating capabilities.

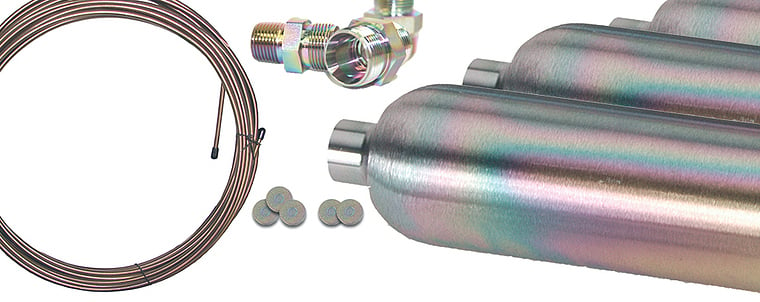

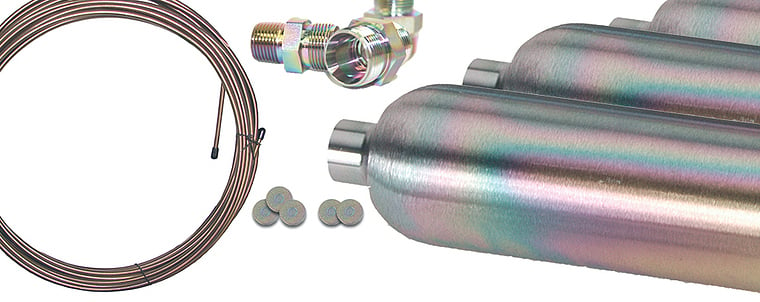

Install filters in the flowpath

Particulates can damage silicon surfaces, especially when moving at high velocity. Particles can also react with process fluids or adsorb sample compounds, contaminating the flowpath. Installing fritted filters in the sample flowpath will prevent system contamination and avoid potential damage to SilcoTek® coated surfaces. Worried about activity in sintered metal frits? SilcoTek® can coat metal filters, helping analysts maintain system inertness while preventing particulate contamination.

Too much to remember? Here's a coating care guide to help keep your inert coating running at peak performance.

How long will SilcoTek coatings last?

It's not unusual to find a coated part still performing at peak inertness after many, many years of service. It all depends on the severity of the environment.

For critical or severe environments, it's a good idea to inventory key coated components and monitor performance over time. Depending on the process environment and use, some customers recoat components periodically as part of an overall preventative maintenance program. Others monitor performance and if they find inertness is declining due to surface damage or contamination; they'll send the used part back to us for recoating. Most likely, the part will perform well over the life of the system and won't need to to be recoated, but for critical applications, it's prudent to monitor performance.

Follow the easy tips highlighted above and you'll find living with SilcoTek coatings is easy and profitable. That's because you'll get better peak resolution, sensitivity and analytical system reliability.

Have more questions about our coatings? Go to our Frequently Asked Questions page.