From a coating company long ago and far far away comes a story about how our coatings contribute to the rebel cause of freeing the galaxy! **

May the 4th be Coated With You!

With May the 4th's arrival, our team of Scientists and Engineers got together to brainstorm ideas on how our coatings can help the rebel cause! The team spent hours pouring through Star Wars episodes to gain insight into how our coatings can contribute to the alliance. Others will call this painstaking research "Friday movie night", you decide if the fourth is with us!

|

In this blog post you will learn:

- How SilcoTek® Coatings improve the performance of a wide range of surfaces long ago in a galaxy far far away.

- Discover the potential of SilcoTek® coatings in a wide variety of real world applications.

- What science nerds do in their spare time.

|

After our research was complete and after several "beverages" were consumed, the Science and Engineering Team sat down to brainstorm about the future of coating applications in past galaxies. Confused? Join the club. Read on to learn how our coatings could be used to defeat the evil empire.

After brainstorming, the team collated the data and came up with the key target needs of the rebellion. Then we applied our coating technology (current and future) to solve the problem. Here are the team's take-aways.

Problem / Need: Coating Technology to Reduce Carbon Fouling from Light Saber Strikes

The team discovered through painstaking research that Light Saber strikes on alloy surfaces produce a significant amount of carbon fouling. This in turn can result in fouling of filters and sensors and potentially bring down a speeder bike. That can ruin a rebel fighter's day!

SilcoTek anti fouling coatings reduce the build-up of carbon from light saber strikes, helping to improve surface durability when that confrontation with a light saber occurs.

/SilcoKlean%20Carbon%20Deposits.png?width=465&name=SilcoKlean%20Carbon%20Deposits.png)

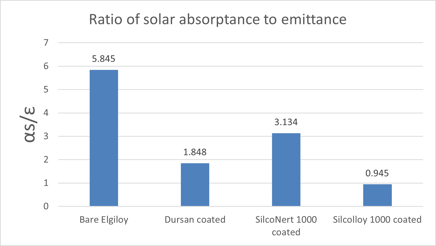

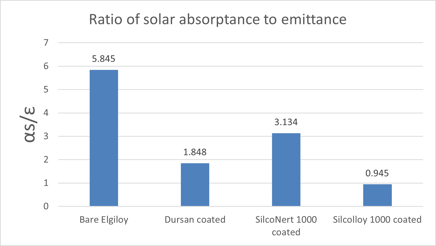

Problem / Need: Emissivity Enhancing coating to increase x-wing durability in application of bouncing through battle station magnetic fields.**

The research team found an opportunity to improve the durability of x-wing craft performance when experiencing shock while bouncing through battle station magnetic fields. In this case the team theorized that higher emissivity or a neutral emissivity to absorption ratio may result in less stress on x-wing craft. This will increase flight hours and keep the rebellion flying!

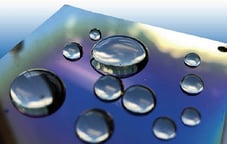

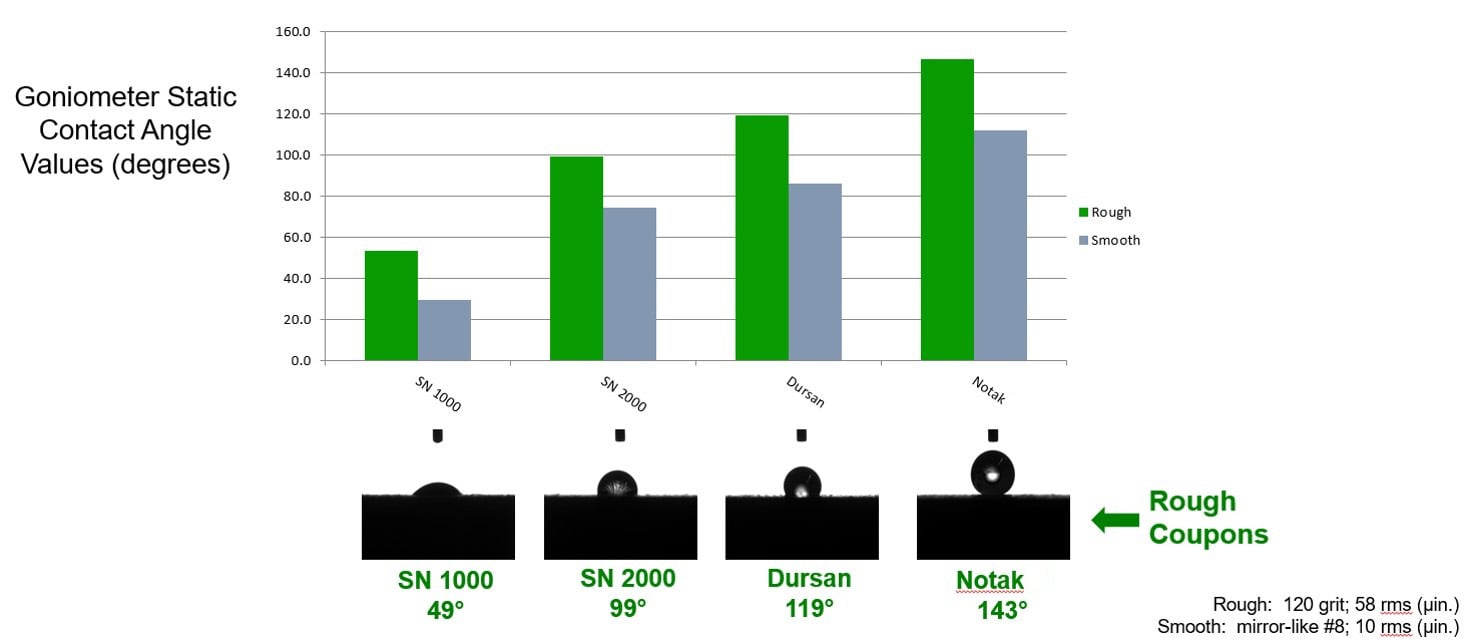

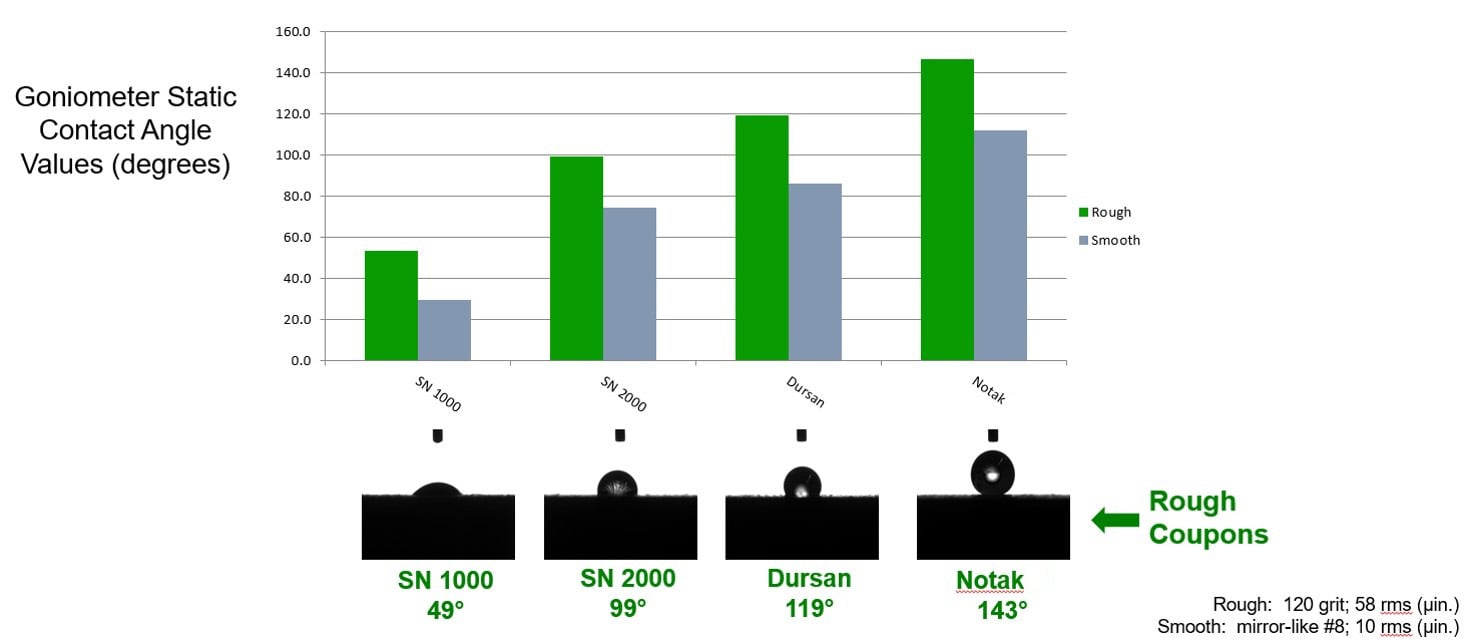

Problem / Need: Develop a self-cleaning ominiphobic coating for wet landings on Degobah.

If you've ever visited Degobah during the wet season you know that it is WET! Extreme humidity, torrential rains and unrelenting wet bogs can damage even the most stout craft. Surfaces that repel water or, even better, repel most substances and self-clean Degobah mud will prevent damage to x-wing craft sensors.

Additionally, our coatings will improve corrosion resistance and reduce the amount of mud that clings to surfaces during liftoff! This will lighten the load and help Luke use his Jedi powers to lift the craft out of the bog. Heck that x-wing will be so light, Luke could probably read the morning paper while lifting old AA-589 out of the bog. For now, our hydrophobic coatings will do a fine job of repelling that Degobah water while improving corrosion resistance.

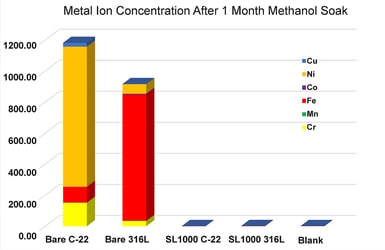

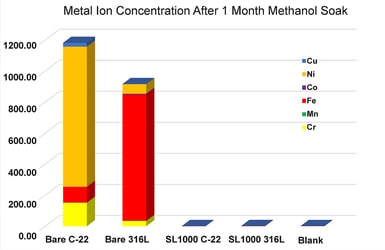

Problem / Need: Longer life through reduced metal ion leaching from protocol droids immersed in biomass slurries found in trash compactors.

In deep space everyone loves and relies on their droids. They provide critical information and often save the day and in the process save their owner's life. But when the Evil Empire tosses your favorite droid into a trash compactor what to do? Not only can R2-D2 get crushed, that pesky trash slurry can play havoc with your droid's sensors and alloy shell.

Under the most challenging conditions found in alien trash compactors, slurries can leach metal ions from the surface and eventually pit droid surfaces. And nobody like a pitted droid.

Recent ion leaching studies by SilcoTek demonstrate the ability of our coatings to prevent metal ion leaching. Methanol, found in compactor slurry, can leach metal ions from the surface, testing shows how SilcoTek coatings prevent leaching and improve corrosion resistance.

Problem / Need: Easy Clean coatings for cantina walls to prevent blaster scoring prior to Cinco de Mayo.

The last time I spent Cinco de Mayo on Tatooine, my favorite cantina looked a little shabby. The unruly crowd letting loose the occasional blaster has left the walls scored and unsightly. Certainly not up to the standards of many Tatooinites!

The R&D Team has pledged to develop a new easy clean coating for the cantina walls that will resist those pesky baster strikes. Chalmun, the Wookiee owner of the Cantina in Mos Eisley on Tatooine, enthusiastically supported the effort, saying "raaaaaaHHgH raaaaaahhgh aarrragghuuhw wrrhw". Which I think translates to "that sounds great", either that or "I'm going to eat you". I'm not sure which...

Problem / Need: Reduction of blaster scoring on Beskar armor through use of novel coating technologies**

When those blasters do strike home you're going to need the toughest armor protection available. When it comes to personal protection, Mandalorian Beskar armor is some of the best. Baskar armor has been around for years but the armor has evolved over the years to include custom high tech accessories. So you'll always have the latest technology at your finger tips. Owners love their armor so much that they paint their beloved Beskar with special or historic paint schemes. The armor is handed down through the generations for not only protection but to tell a story of family and history. Now imagine a blaster strike mars that custom paint job. Ugg, that really infuriates your average Mandalorian!

When those blasters do strike home you're going to need the toughest armor protection available. When it comes to personal protection, Mandalorian Beskar armor is some of the best. Baskar armor has been around for years but the armor has evolved over the years to include custom high tech accessories. So you'll always have the latest technology at your finger tips. Owners love their armor so much that they paint their beloved Beskar with special or historic paint schemes. The armor is handed down through the generations for not only protection but to tell a story of family and history. Now imagine a blaster strike mars that custom paint job. Ugg, that really infuriates your average Mandalorian!

To help Mandalorians protect their heritage, and more importantly to prevent them from storming our facility in protest; the SilcoTek Science Team has begun work on super high durability coatings to enhance Beskar armor and to better protect against blaster surface damage. Have a product or process that needs protection? Get our Instrument Technical Insight!

Problem / Need: Low conductivity coating to reduce damage from force lightning.

Ever been hit by force lightning? Let me tell you it's not fun getting shocked into submission and being thrown against a wall by the pure force of a well directed bolt. In fact, the Engineering team is so fed-up with force lightning ruining their day that they've started work on a new low conductivity coating to prevent the transfer of electrical shock. When our low conductivity coating is available, not only will you be able to tell the evil Sith to take a hike, you can laugh while doing it!

Are silicon CVD coatings durable? Learn more about our coating properties, all available now!

Problem / Need: Low surface energy coating to reduce bio-fouling as a result of Purrgil collisions.

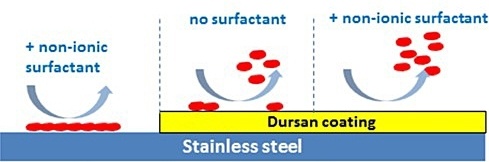

I've been lucky enough to not have had a collision with a Purrgil while in hyperspace, but some of my fellow galactic travelers have. They'll tell you a Purrgil collision can be a messy experience for both humans and Purrgil. To help protect the ship from bio-fouling during collisions, the R&D Team will enhance our bio-inert coating, Dursan®, to better resist all bio related fouling. To learn more about our real world bio inert coatings, read our Medical Diagnostics and Bio Inertness E-book.

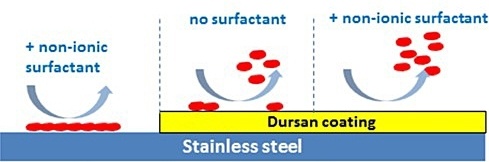

Right now Dursan® does an excellent job preventing protein carryover and contamination. In conjunction with a non-ionic surfactant, Dursan coated surfaces significantly reduce protein contamination.

Problem / Need: Inert coatings to enable trace detection of Rhydonium

When fueling your starship you don't want highly volatile rhydonium from leaking or contaminating the environment. That's why our Science Team is working to further improve the sensitivity and trace detection of volatile compounds like rhydonium. Because rhydonium is so explosive, detection and management of the fuel is critical. That's why we're pushing the limits of reliable detection to part-per-quadrillion levels. Soon you'll be able to fuel that starship with confidence! *

No matter where your journey takes you, we're here to enhance the performance of your products and processes. Even long ago in a galaxy far far away!

May the fourth be with you!

Want to learn more about how our Scientists and Engineers can improve the performance of your products? Read about CVD coatings for space exploration, follow us on LinkedIn, or subscribe to our emails and blog.

* Lego Death Star Courtesy of Connor White, Image Courtesy of Geoff White

**Images Courtesy of Geoff White

References and Further Reading (If you've got time on your hands!)

https://www.starwars.com/databank/force-lightning#:~:text=Force%20lightning%20is%20a%20dark,weapon%2C%20it%20is%20not%20unstoppable.

https://starwars.fandom.com/wiki/Rhydonium

https://starwars.fandom.com/wiki/Mandalorian_armor/Legends

https://starwars.fandom.com/wiki/R2-D2_and_C3PO_%E2%80%93_Trash_Compactor_Rescue

https://www.wookietranslator.com/

https://en.wikipedia.org/wiki/Dagobah

https://en.wikipedia.org/wiki/Mos_Eisley#:~:text=Located%20on%20the%20planet%20Tatooine,a%20particular%20impact%20on%20audiences.

/SilcoKlean%20Carbon%20Deposits.png?width=465&name=SilcoKlean%20Carbon%20Deposits.png)

When those blasters do strike home you're going to need the toughest armor protection available. When it comes to personal protection, Mandalorian Beskar armor is some of the best. Baskar armor has been around for years but the armor has evolved over the years to include custom high tech accessories. So you'll always have the latest technology at your finger tips. Owners love their armor so much that they paint their beloved Beskar with special or historic paint schemes. The armor is handed down through the generations for not only protection but to tell a story of family and history. Now imagine a blaster strike mars that custom paint job. Ugg, that really infuriates your average Mandalorian!

When those blasters do strike home you're going to need the toughest armor protection available. When it comes to personal protection, Mandalorian Beskar armor is some of the best. Baskar armor has been around for years but the armor has evolved over the years to include custom high tech accessories. So you'll always have the latest technology at your finger tips. Owners love their armor so much that they paint their beloved Beskar with special or historic paint schemes. The armor is handed down through the generations for not only protection but to tell a story of family and history. Now imagine a blaster strike mars that custom paint job. Ugg, that really infuriates your average Mandalorian!