While all of the rules are not fully in place yet, the Environmental Protection Agency (EPA) proposed the Inflation Reduction Act (IRA) in 2021 and signed into law in 2022 requiring most companies to reduce methane (CH4) gas emissions. This change could mean big charges for some designated petroleum and natural gas facilities starting January 1, 2024. Not to worry, SilcoTek can help with your emissions monitoring systems to determine if these new charges apply to your company.

New Methane Gas Monitoring Regulations: How SilcoTek Can Help

What You Need to Know:

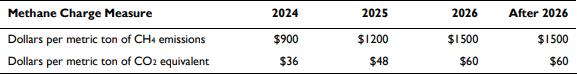

- According to a recent article by Jones Day, "the first step in calculating the methane charge is to determine the applicable threshold below which the charge does not apply. The threshold varies based on the type of facility. For example, the threshold for methane emissions from onshore and offshore petroleum and natural gas production is an amount that exceeds 0.20% of the natural gas sent to sale from the facility or 10 metric tons of methane per million barrels of oil sent to sale from the facility if it sent no natural gas to sale. For non production petroleum and natural gas systems, the threshold is 0.05% of the natural gas sent to sale from or through the facility. Finally, for onshore natural gas transmission compression or transmission pipeline or underground natural gas storage, the charge applies to methane emissions that exceed 0.11% of the natural gas sent to sale from or through the facility."

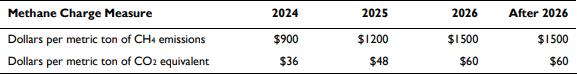

- Methane Charge Rates

What Does This Mean for SilcoTek Customers?

When determining if your company complies with the thresholds established by the IRA, you will need to monitor and analyze your emissions. SilcoTek coated products can help you get the perfect inert surface to ensure consistent and accurate results. For many, emissions monitoring encompasses a variety of different VOCs, mercury, sulfurs, and aromatics, so SilcoTek coated equipment could prove to be beneficial in more than one way.

SilcoNert® 2000 coated sample paths can improve emissions monitoring of Sulfur, SO2, H2S, CH4, and VOC detection in refinery, process, stack, CEM, and flare sampling systems. Our SilcoNert 2000 coating prevents adsorption of controlled gases within the analytical flow path. Although SilcoNert isn't necessarily required to determine if you meet the new methane thresholds, many other gases require an inert surface to accurately detect certain levels. It is rare that you would be testing for methane alone, though.

Examples of Monitoring Equipment we Can Coat:

- Tubing

- Fittings

- Valves

- Sample Probes

- Sample Cylinders

- Pressure Regulators

- Flow Meters

- Air Cans

- Transfer Lines

- Packed / Micropacked Columns

- More...

To maintain compliance to all EPA regulations, new and old, SilcoNert 2000 coating is the ideal solution for an inert, non-reactive silicon surface that makes the entire flow path better for process control, consistent sampling, and analytical results.

Accurate and reliable test results are illustrated below when testing Sulfur, VOCs, and Methanol using SilcoNert 2000 technology.

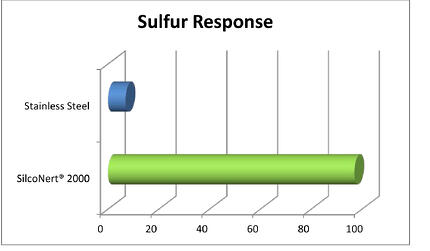

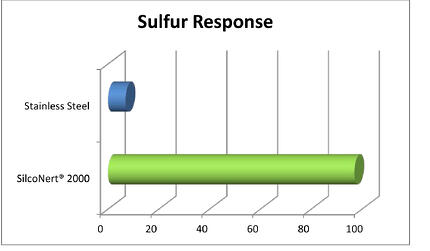

Sulfur Testing

We compared coated and uncoated sample pathways and measured the signal response and signal stability. The graph below compares the relative response of uncoated stainless steel and SilcoNert coated stainless steel flow paths. The SilcoNert coated pathway offers faster response and drastically improves signal stability.

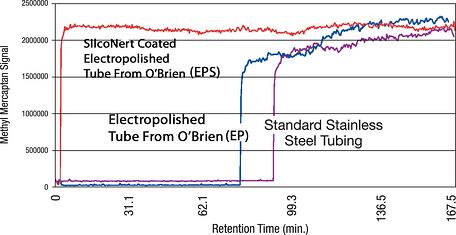

Looking further into absolute response time, SilcoNert® 2000 dramatically improves sulfur detection and response. Sulfur response in a relatively short 100ft length of tubing (below) can be reduced from hours to seconds by coating wetted flow paths with SilcoNert 2000.

VOC Measurement

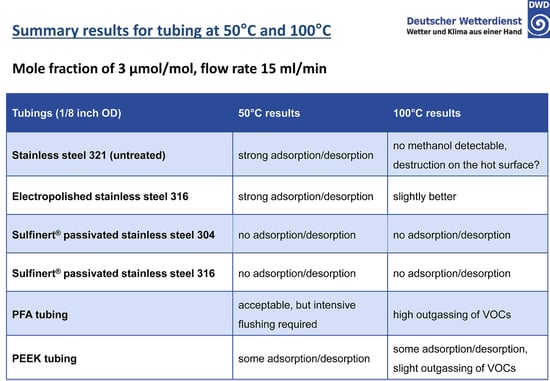

Selecting inert and durable materials for sampling critical flowpath surfaces can be a key factor in successful analysis. Mr. Stefan (S.T.) Persijn of VSL, Dutch Meteorological Society, (in conjunction with the German Meteorological Office, DWD) presented a comparative study of adsorptive properties of various materials commonly used in VOC analysis (Gierschner et al.)

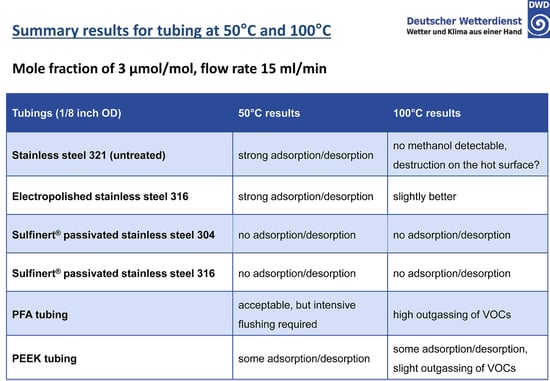

The study exposed various tube surfaces to methanol at 50 and 100°C and measured adsorption rate of the surfaces. Results show that an inert coating like SilcoNert® coated stainless steel prevented adsorption and reaction with VOCs in critical flow paths. The study summary, below, highlights the comparative results:**

The untreated stainless steel readily adsorbs active compounds with complete loss of methanol. Electropolishing will smooth the surface and reduce overall surface area but adsorption is still significant. PFA and PEEK tubing require careful management of the surface in order to achieve acceptable results. SilcoNert (in this study called by our other trade name, Sulfinert® ) coated stainless steel does not adsorb active compounds because the inert silicon CVD surface bonds to and diffuses into the stainless steel substrate, preventing interaction with reactive sites.

The Key VOCs team completed a major volatile organic compound (VOC) study funded by EURAMET, the Meteorological Observatory Hohenpeissenberg of DWD (the German Meteorological Service) and partnered with the European Metrology Research Programme. Their final report on VOC analysis, "Metrology for VOC Indicators in Air Pollution and Climate Change" is helping to advance the science of trace VOC measurement.**

The team developed test methods to quantify sources of VOC interaction and loss. The project identified suitable materials that prevent adsorption of VOCs and improve measurement techniques. The team also developed sensor based measurement systems for key VOCs in air. The Key VOC team chose SilcoTek® coatings for their study because we offer the expertise, support, and inertness needed to provide an inert sample flow path for highly reliable trace VOC analysis.

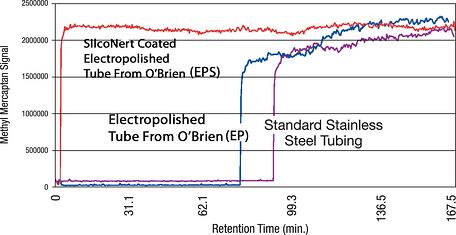

Methanol Comparison

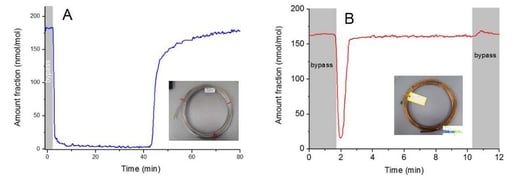

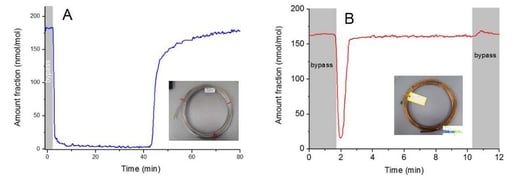

The VOC team then compared 10 meter lengths of SilcoNert 2000 coated and uncoated stainless steel tubing (below). The team passed a 180 umol/mol methanol mixture through a bypass (grey areas), then switched to the test tubing. They measured the time to achieve baseline concentration for each tube. The SilcoNert coated tube took less than a minute to stabilize (graph B) compared to over 40 minutes for the stainless steel tube (graph A). The comparison demonstrates the severe adsorption of trace methanol on stainless steel flow path surfaces and highlights potential delays in response that can lead to significant data reliability issues when conducting trace VOC analysis.

Images and data courtesy of The Dutch Metrology Institute (VSL) and the German Meteorological Office (DWD) presented at the Key VOC joint project April 21st 2016, in Paris, France.

Overall, the least methanol adsorption was observed for polymer sampling lines (like PTFE, and FEP) but porosity/permeability, high temperature stability and durability issues limit their effectiveness in the field. It was found that at elevated temperatures (50 to 100c) polymer tubing emitted trace compounds which can lead to unwanted or spurious signal peaks. The SilcoNert coating is stable to 450C and emits no trace compounds during heating.

The study stated: "The adsorption by most polymers such as PTFE and FEP is extremely low, while for uncoated metals it is very high. Coated stainless steel with Silconert-2000 and Sulfinert are the preferred choice, as they also have the benefit of being robust non-permeating materials."

Wondering how SilcoTek can help solve your emissions testing problems? Contact us!

References:

Gierschner, P., Kuntzel, A., Reinhold, P., Kohler, H., Schubert, J.K., Miekisch, W. Journal of Breath Research. 2019. 13, 046006

“Inflation Reduction Act Methane Emissions Charge: In Brief.” Congressional Research Service , 29 Aug. 2022, https://crsreports.congress.gov/product/pdf/R/R47206.