We discuss the benefits of bio inert coatings in medical diagnostics, HPLC, and pharmaceutical manufacturing. Learn why USP Class VI compliance is important.

The benefit of Bio Inert Coatings for HPLC Diagnostics and Pharma

|

In this blog post you will learn:

- Get details about how surfaces are tested for bio-toxicity.

- How Dursan® performed under USP Class VI test conditions.

- Learn about the performance benefits of CVD coatings (like Dursan® and Silcolloy®) including, bio inertness, metal ion contamination prevention, and corrosion resistance.

|

Silicon coatings applied by chemical vapor deposition (CVD) have unique properties that benefit laboratory instrumentation performance in HPLC, bio analytical, and pharmaceutical manufacturing applications. CVD physical properties allow micro flow paths, like needles, to be coated without significantly changing the dimensional or physical properties of the surface. But more importantly, CVD coatings like Dursan allow the analyst to perform more tests reliably with better resolution, improved test quality, and with less potential for contamination from the flow path.

In this blog post we'll discuss some of the features and benefits of CVD coatings in bio pharma and medical diagnostic applications.

Want to keep up with the latest in coating technology for analytical and medical diagnostics? Click on the box below to subscribe to our informative emails and blog it's easy and you won't get a lot of useless emails!

Coating Benefits

Inert coatings, like Dursan, prevent protein binding and carryover in analytical systems and prevent system cross contamination while preventing ion contamination, improving corrosion resistance, and test quality. Dursan is non toxic, meeting USP Class VI standards, and can be applied to more durable base materials (like stainless steel) to improve inertness performance over less durable materials like PTFE.

Let's discuss some of the unique features and benefits silicon CVD coatings offer.

Non Toxic USP Class VI Compliant

The United States Pharmacopeia and National Formulary (USP-NF) is a non-profit organization responsible for testing materials (usually single use plastics) for bio-toxicity. The goal of the testing is to be sure no toxic materials will be extracted when a product comes in contact with human tissue or injectable drugs or other products manufactured relating to healthcare, pharmaceuticals, or medical devices.

Class VI testing has the most stringent criteria and involves 3 tests that evaluate reactions for toxicity in tissue. Passing the test means the material is not toxic and does not leach potentially harmful substances into fluids or tissue.

How Dursan Performed

Dursan® passed all toxicity tests while maintaining superior inertness, durability, and corrosion resistance. Dursan exhibited no additional reaction or toxicity when compared to an inert blank sample. You can view the results and Class VI certification by going to our Certification and Compliance page. Or you can click on the box below:

Why is USP Class VI Certification Important?

There are plenty of silicone products and other medical grade plastics that are USP Class VI compliant. There's even a silicon carbide surface that's compliant and various release agents used in the manufacture of silicone plastics are compliant. But Dursan® is one of the first CVD silicon coatings to achieve USP Class VI compliance.

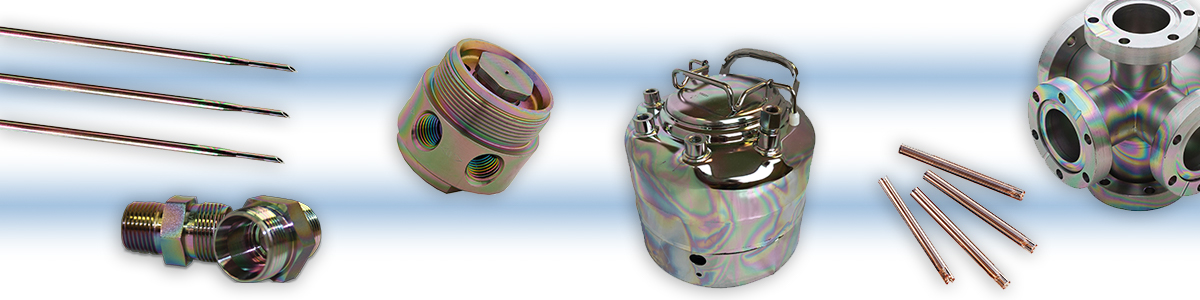

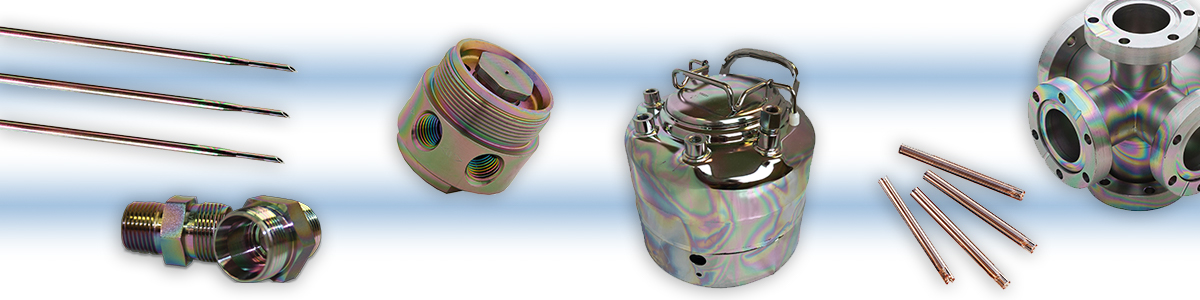

Why is that important? Because silicon (think semiconductor chip material) applied by chemical vapor deposition (CVD) allows complete coverage of surfaces both internally and externally. CVD coatings can be economically applied to components like fittings, tubing, fritted filters, needles, and most complex or small bore components. The result is a non-toxic bio-inert surface that is USP Class VI compliant.

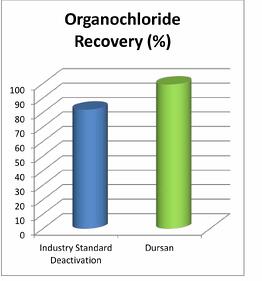

Bio-Inertness: Improving Protein Analysis in HPLC

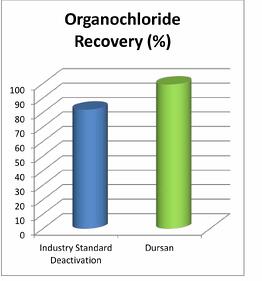

Medical device manufacturers, diagnostic equipment and HPLC instrumentation used for protein analysis benefit from the durability and unmatched chemical inertness of Dursan® coated stainless steel and glass. Inert silicon surfaces allow for improved recovery of compounds over standard deactivation methods as seen in the test results below.

For bio-compatibility, confidence, and consistency, use Dursan® on new or existing components.

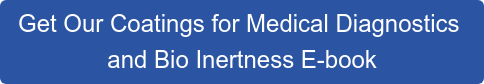

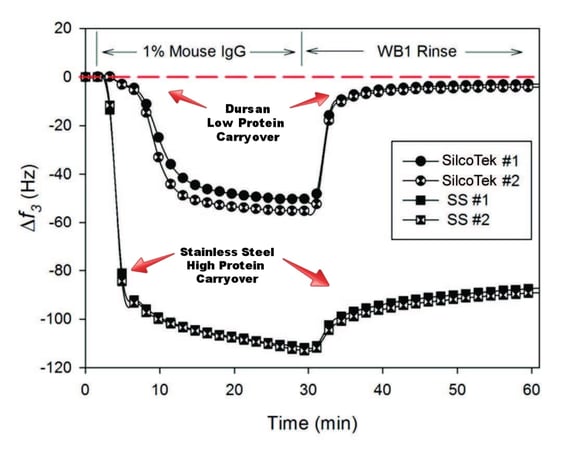

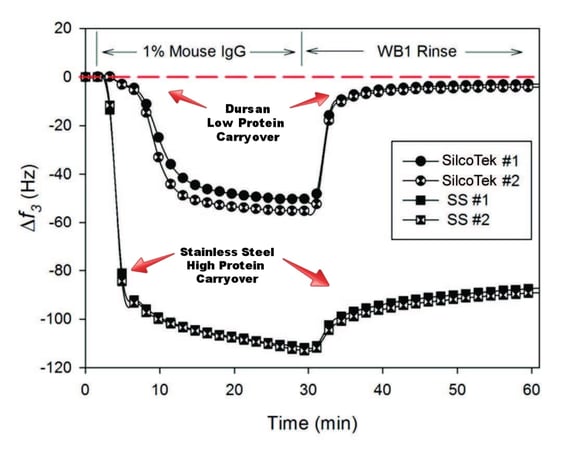

The protein-resistant properties of Dursan were studied using quartz crystal microbalance with dissipation monitoring (QCM-D), and compared performance to a bare stainless steel sample.

With the assistance of a nonionic surfactant-containing wash solution, Dursan® was found to facilitate nearly 100% removal of adsorbed proteins (BSA, mouse IgG and NHP), whereas these proteins remain adsorbed on the bare stainless steel surface under the same conditions.

Use Dursan® on a wide range of biotechnology equipment:

- HPLC columns and hardware

- Medical diagnostic equipment

- Biomedical devices

- Needles

|

Prevent Metal Ion Contamination

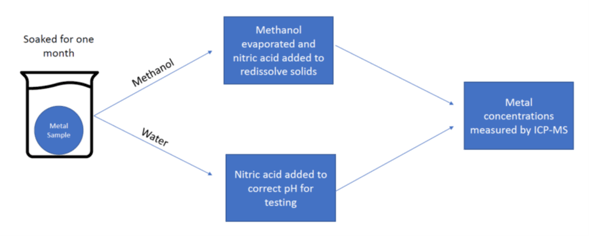

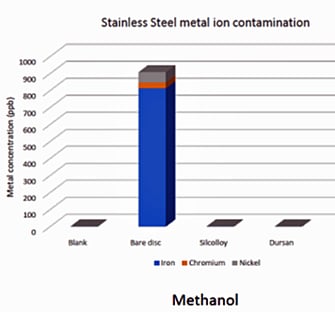

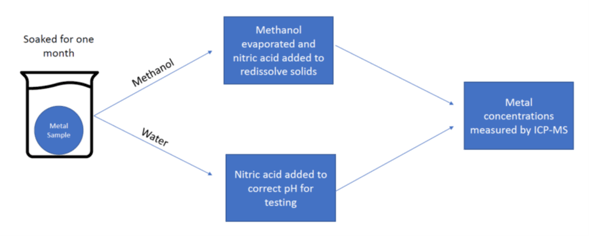

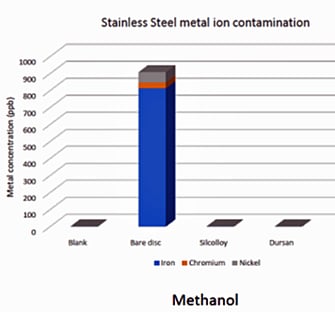

Porous C-22 Hastelloy and 316L stainless steel discs with 10 µm nominal pore sizes were purchased from Mott Corporation. They were coated with Silcolloy silicon barrier coating. After coating, the discs were placed in 50 mL of HPLC grade methanol and sealed. Uncoated discs as well as a container with no disc (a solvent blank test control to establish baseline response) were also filled with methanol and sealed. After one month of soak time, the porous disks were removed from the methanol and the samples were delivered to the Energy and Environmental Sustainability Laboratories at Penn State University. Samples were then prepared by evaporating 10 mL of the methanol in a PTFA vial. The remains were dissolved in 5 mL of dilute nitric acid which was then analyzed using a Thermo Fisher iCap RQ ICP-MS.

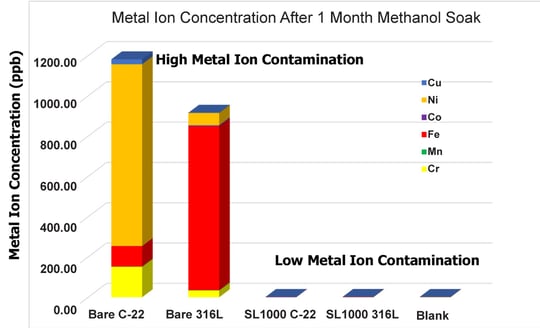

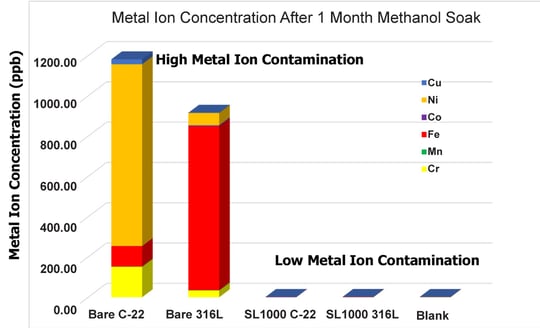

Figure 1 shows the total metal ion concentrations from the solution of each container. The blank represents the level of metal ions in the methanol bottle, leached from the sealed container, sample preparation, or absorbed via environmental sources. The bare Hastelloy and stainless steel discs represent the level of metal ions leached into the methanol without any coating protection provided by processing at SilcoTek® Corporation. The level of metal ion contamination for the uncoated discs was significant, with the Hastelloy discs exceeding 1200 ppb contamination.

The coated discs showed little to no appreciable level of contamination.

Figure 1: Metal ion concentrations in methanol. The blank is methanol from the bottle with no disc. The four others are an uncoated Hastelloy disc, an uncoated stainless steel disc, and two Silcolloy® coated discs soaked in methanol for 1 month at room temperature. The coated discs showed minimal contamination.

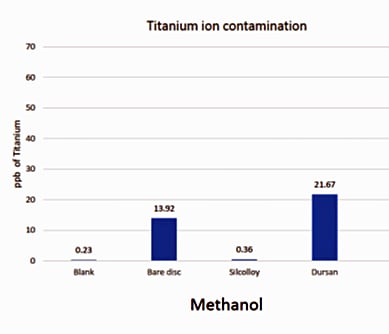

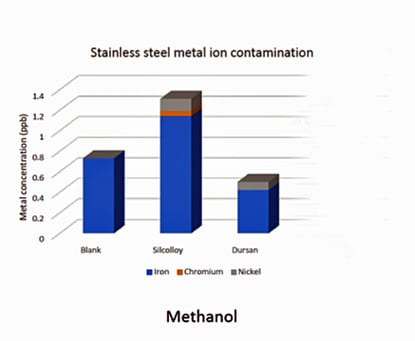

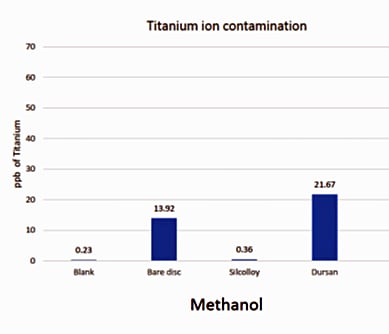

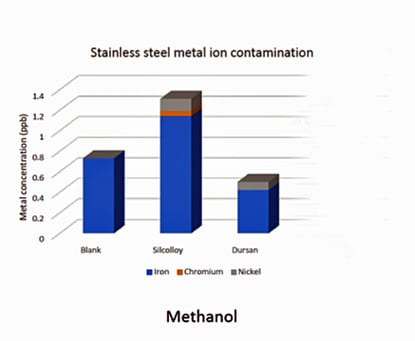

We also tested titanium and stainless steel under similar conditions. The titanium samples below showed improved ion contamination resistance with Silcolloy coated surfaces.

The same held true for stainless steel. Here the uncoated disc showed major metal ion contamination.

After removing the uncoated sample from the test we're able to better see the extreme low levels of metal ion concentration in the coated discs.

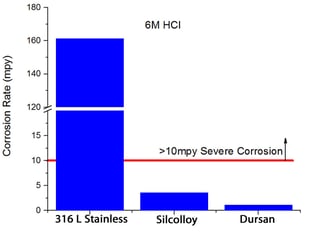

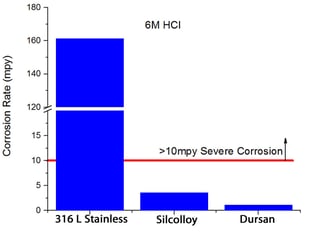

Corrosion Resistance

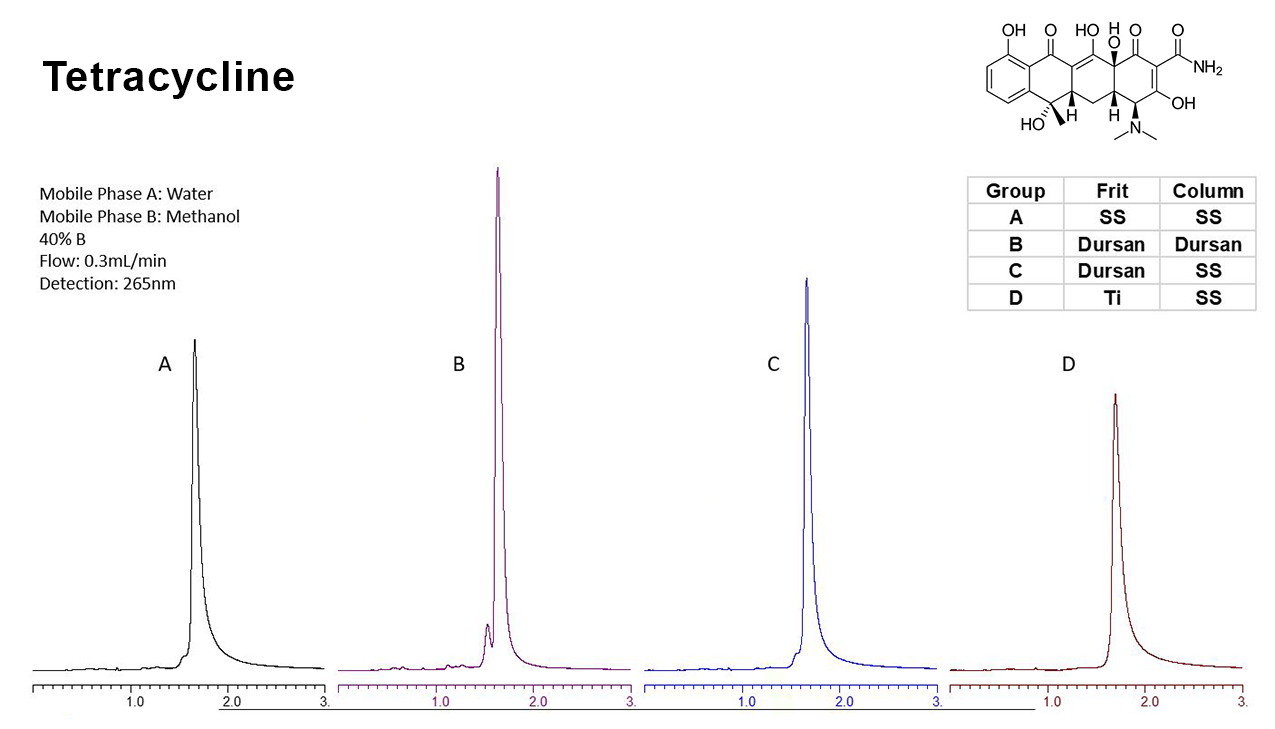

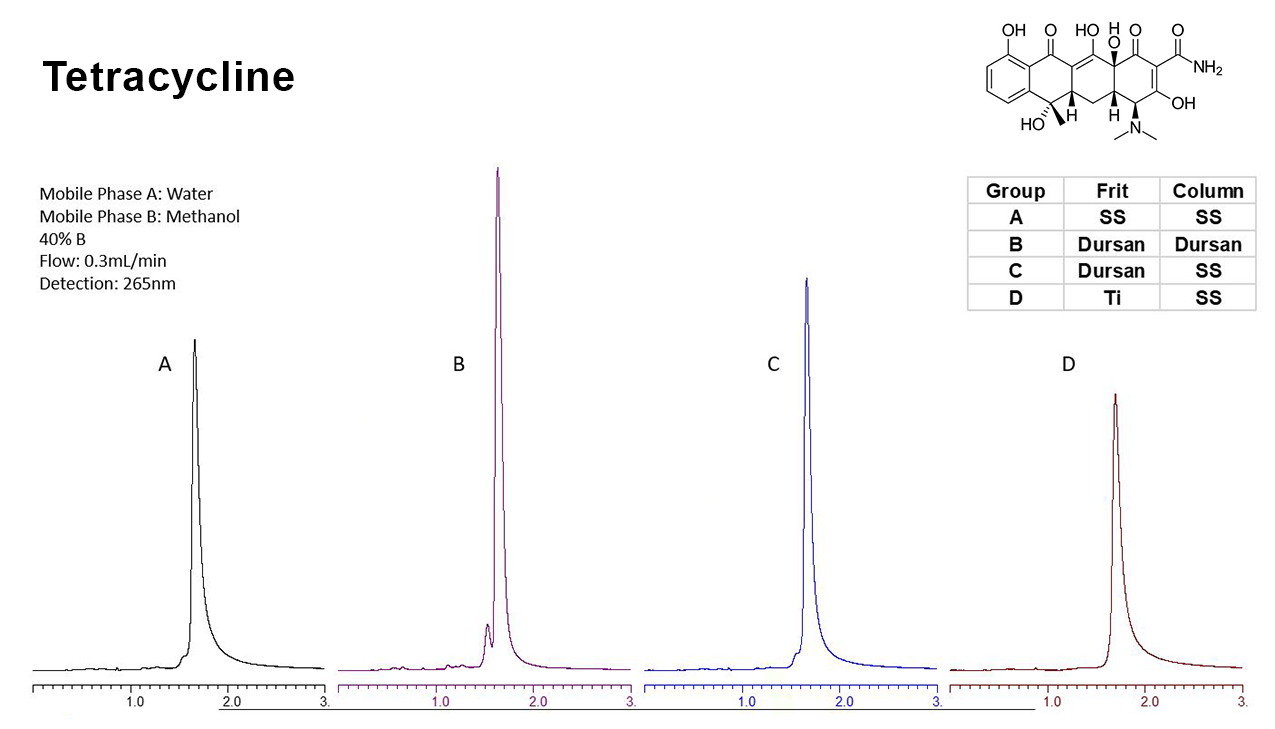

Coating the entire sample flow path with an inert silicon coating, like Dursan® or Silcolloy®, helps to prevent formation of adsorptive instrument corrosion particles and increase the life of the sample system. Rust particles can be tremendously adsorptive, the presence of even a small amount of rust can reduce sampling accuracy, increase calibration failures, and distort peaks. All of which will require more analyst time and money to resolve. Here's an example of the benefit of an inert flow path. Note the improved peak shape and resolution (peak B) when the frit and column are coated.

The Dursan coating technology improves corrosion resistance by orders of magnitude compared to uncoated stainless steel.

Instrument probes, tubing, fittings, filters, and regulators exposed to corrosive sampling streams can be made both inert and corrosion resistant by coating the wetted surfaces with Dursan®.

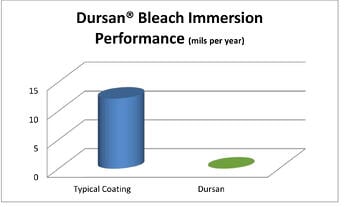

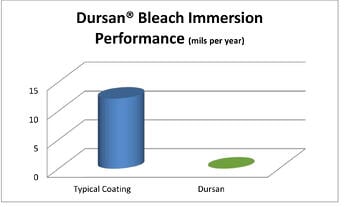

Dursan® prevents sampling component damage and contamination throughout the analytical flow path. Dursan can coat the ID of the smallest needles, improving durability and preventing protein binding to stainless steel surfaces. Bleach immersion testing below demonstrates the superior corrosion resistance of Dursan over uncoated or other coating surfaces.

|

|

| Typical coating after bleach exposure |

Dursan after bleach exposure |

Wear and lubricity:

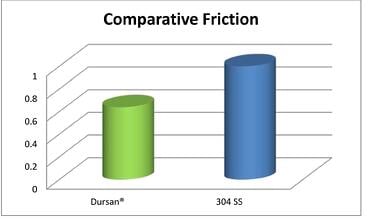

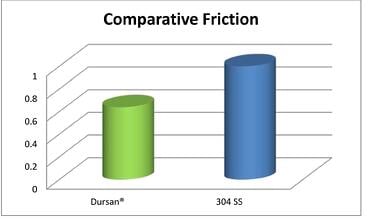

Applications like needles, slider valves or rotating valves can bind under stress; damaging the sampling tool and exposing potentially active sites to your sample and reducing sample accuracy. Dursan® significantly reduces sliding friction and binding, preventing binding or damage to flow path surfaces.

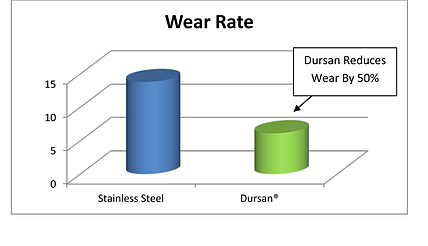

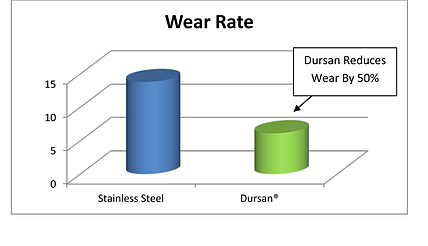

Wear resistance is also improved. Stainless steel surfaces are relatively soft and can erode over time. Erosion can expose potential active sites and reduce system life. SilcoTek's chemical vapor deposition process incorporates a durable coating into the stainless steel surface, enhancing both inertness and durability. While Dursan is not suitable for extremely abrasive environments, the coating will improve durability in particulate rich environments.

Extreme Temperatures:

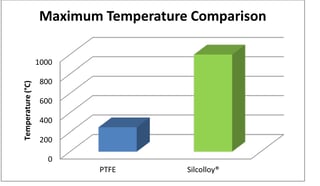

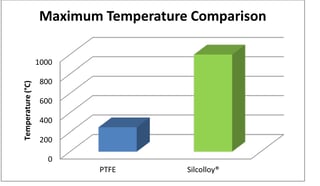

Inert surfaces like PTFE can quickly degrade when exposed to temperatures above 250°c and will become brittle in cryogenic environments. Sampling cryogenic liquids or exposure in high temp reactors can easily exceed the capabilities of PTFE and other coatings. SilcoTek® offers inert coating solutions for environments ranging from -270°c to 1000°c, allowing accurate sampling without damaging the sampling pathway.

Watch our freeze test video:

Have a bio-inert coating question? To learn more about how Dursan can improve bio-inertness contact our Technical Service Team or follow us on LinkedIn.