Some people welcome the leaves turning, lower temperatures, and are enjoying their pumpkin spice lattes. If you're anything like me, this time of the year is always a drag. As the weather inches closer to colder temperatures, we wanted to discuss how SilcoTek coatings perform in low temperature environments.

Performance Enhancing Coating for Low Temperature Applications

Above is a picture I took at my favorite place, Lake Raystown in Entriken, PA, showing the leaves changing last fall.

In this blog post, we will demonstrate that our coatings are strong against extremely low temperatures sometimes found in process manufacturing settings. While other treatments fold in the cold, SilcoTek's Dursan® coating stays strong and continues to perform. Our coatings are proven to endure some of the most challenging environments. From high temperature exposure to low temperature cryogenics, acid to base or salt exposure, our CVD coatings take intense abuse and continue to protect the equipment in your process.

Most SilcoTek coatings are amorphous. An amorphous structure enables the coating to bend or deform to some extent. This allows our coatings to flex, bend, expand, and contract with the substrate surface. That means during extreme changes in temperature, the coating remains intact and bonded to the substrate. Thermal shock, heat cycling, and low temperature cryogenic exposure won’t cause the coating to fail as long as the substrate remains intact. Watch the video below to see how our coatings perform under extreme low temperature conditions.

What about icephobicity?

For icephobicity, we would recommend our Notak® coating. Low energy surfaces that prevent ice adhesion may provide substantial benefits for applications utilizing heat exchangers, as well as applications that are negatively affected by the accumulation of ice. Notak has a low surface energy of approximately 10.5 mN/m compared to an untreated 316 SS surface of approximately 45.8 mN/m. This low surface energy may allow ice to release from a Notak surface with little effort.

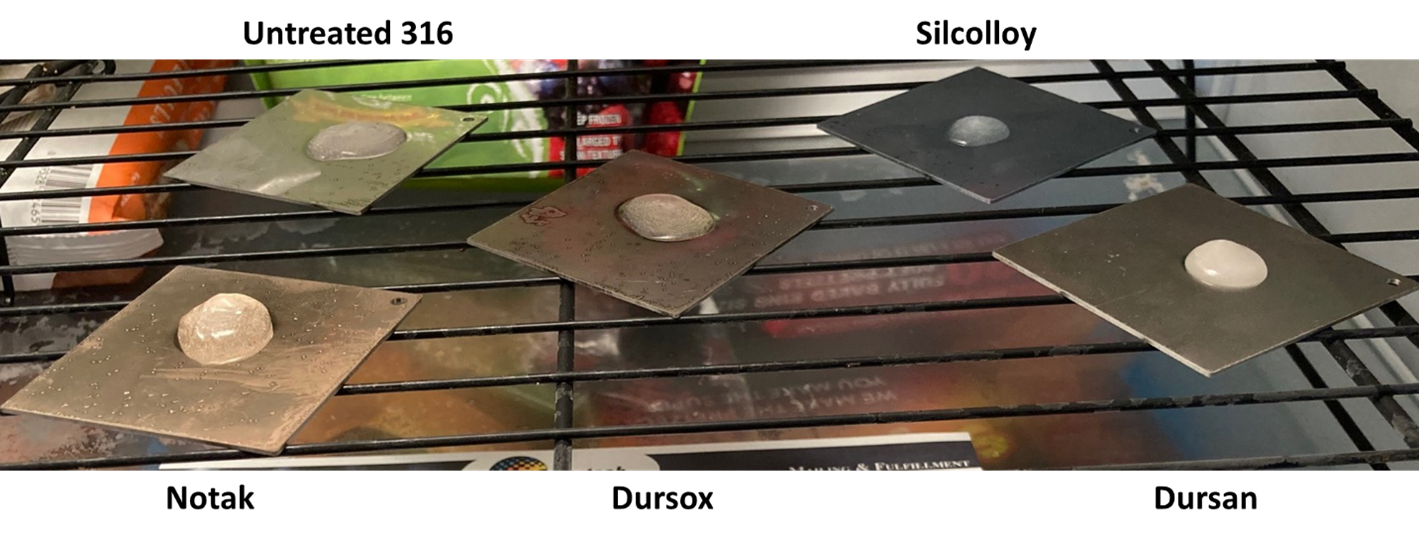

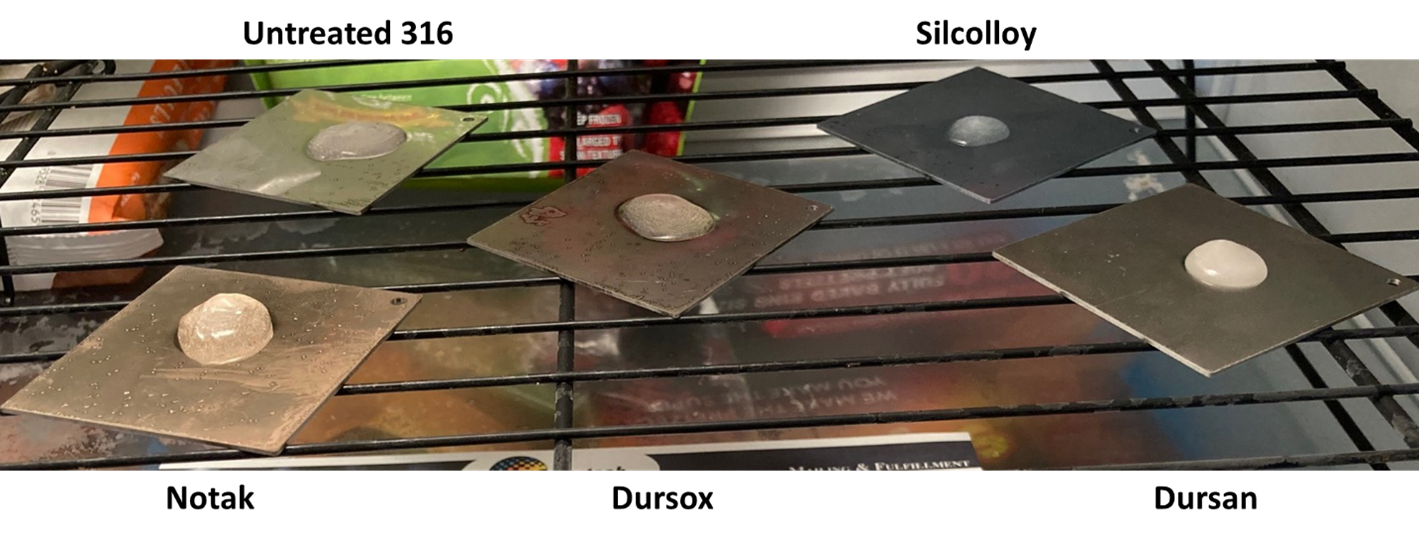

In 2020, SilcoTek's Dr. David Smith conducted a study to compare the icephobic properties of coupons with various SilcoTek surfaces and an uncoated control. The coupons were placed on a rack within a commercial freezer at 0°F / -18°C. Upon placement, approximately 1-2ml of DI water was dropped on to the center of a coupon. The coupons resided in the freezer with the door closed for 16 hours. Upon opening the freezer door (see photo), each coupon was individually removed and rapidly tested to avoid the potential impact of thawing. A metal pick inserted at the point of ice attachment to the coupon was used to laterally remove the ice. The effort required (1 = easy, 10 = difficult) to remove the ice and associated observations are listed in the table below.

| 316 SS Coupon Surface |

Effort (1-10) |

Observations |

| Notak |

2 |

Complete removal with little effort |

| Dursan |

6 |

Partial removal from surface with effort |

| Silcolloy 1000 |

7 |

Partial removal from surface with greater effort |

| Dursox |

8 |

Difficult, bulk chipped with minimal surface separation |

| Uncoated |

8 |

Difficult, bulk chipped with minimal surface separation |

The subjective data indicates an opportunity for the application of Notak surfaces for the prevention of ice accumulation and/or provide ice release with little effort. If you want to read more about this study, please download the complete icephobicity study.

The coating bond strength and amorphous nature of the CVD coating structure will remain intact during wide temperature changes, allowing the coatings to be used in extreme thermal environments.

We discuss the high temperature limitations of our coatings in this previous blog post.

Want to know if we can help in your application?