Having trouble measuring a coating? We discuss how to measure thin film coating thickness.

At SilcoTek® we specialize in applying ultra thin coatings to stainless steel and other metal alloys, glass, and ceramic surfaces. We often measure our coating thickness as part of our quality control and coating development. We learned that measuring thin silicon coatings can be tricky. Here are some tips on how to measure coating thickness.

Have a question about this blog or coating thickness measurement? Click the box below to discuss your application with one of our coating scientists.

Have a Question? Contact Our Technical Service Team

|

In this blog post you will learn:

- Techniques and ASTM methods for measuring thin coatings.

- How the base surface material and coating material can dictate coating measurement techniques.

- How super thin coatings can make accurate thickness measurement difficult.

- How basic measurement tools commonly used for paints and thin films won't cut it when measuring micro thin coatings.

|

In the early days of SilcoTek coating development (30+ years ago) our knowledge of coating measurement techniques was limited to only a few rather expensive test methods. We found that other thickness measurement techniques just didn't have the precision and capability to measure a super thin silicon coating on stainless steel. Since those early days of trial and error coating development, we've learned what works and doesn't work when it comes to measuring CVD coatings.

Want to learn more about how to evaluate and characterize a coating? Read our Surface Characterization Blog Post.

Here are some examples of coating thickness measurement tools and methods. If you have a question about our coatings, our Technical Service Team is here to help you select the best coating for your application.

Our team can:

Want more in-depth information about our coatings and learn how they improve the performance of products and processes in challenging applications?

Go to our Coating Applications Page

Coating Thickness Measurement Tools

Auger Electron Spectroscopy (AES)

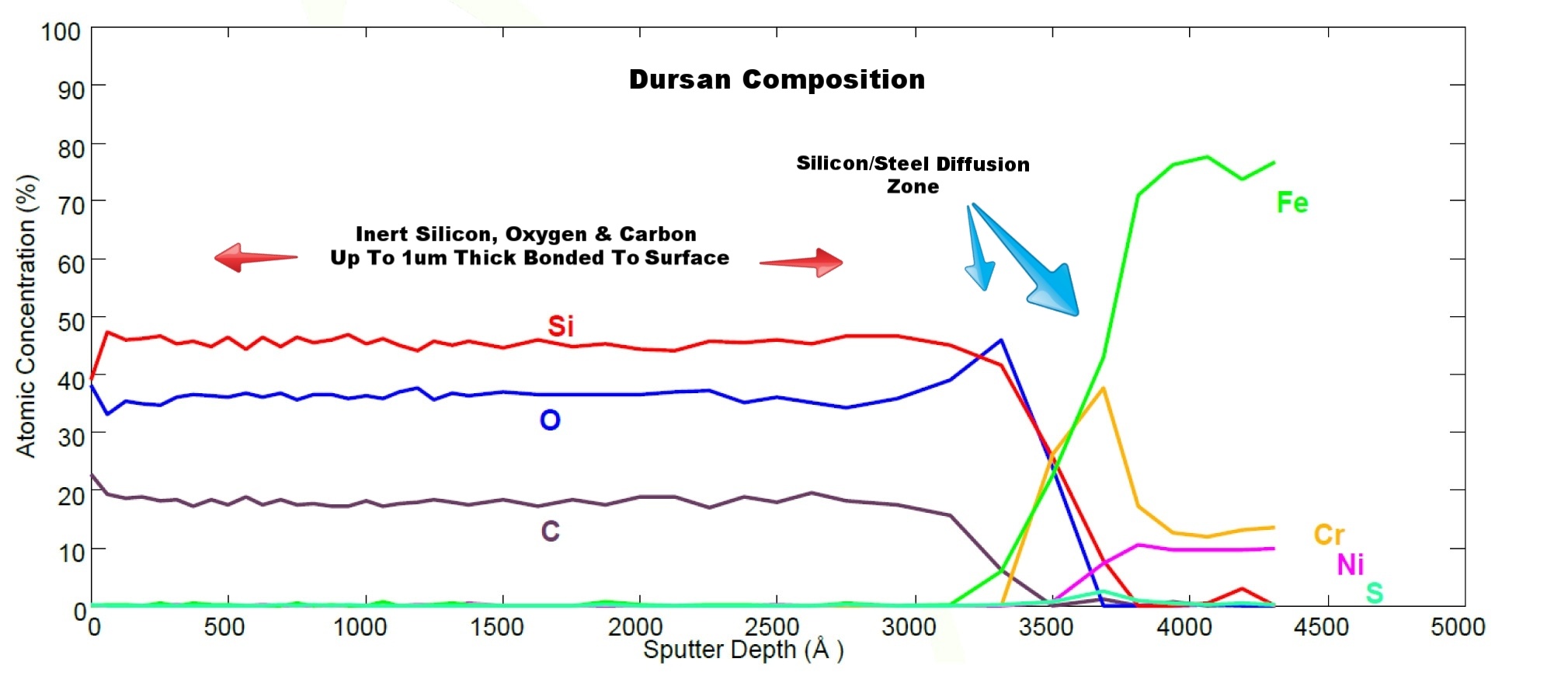

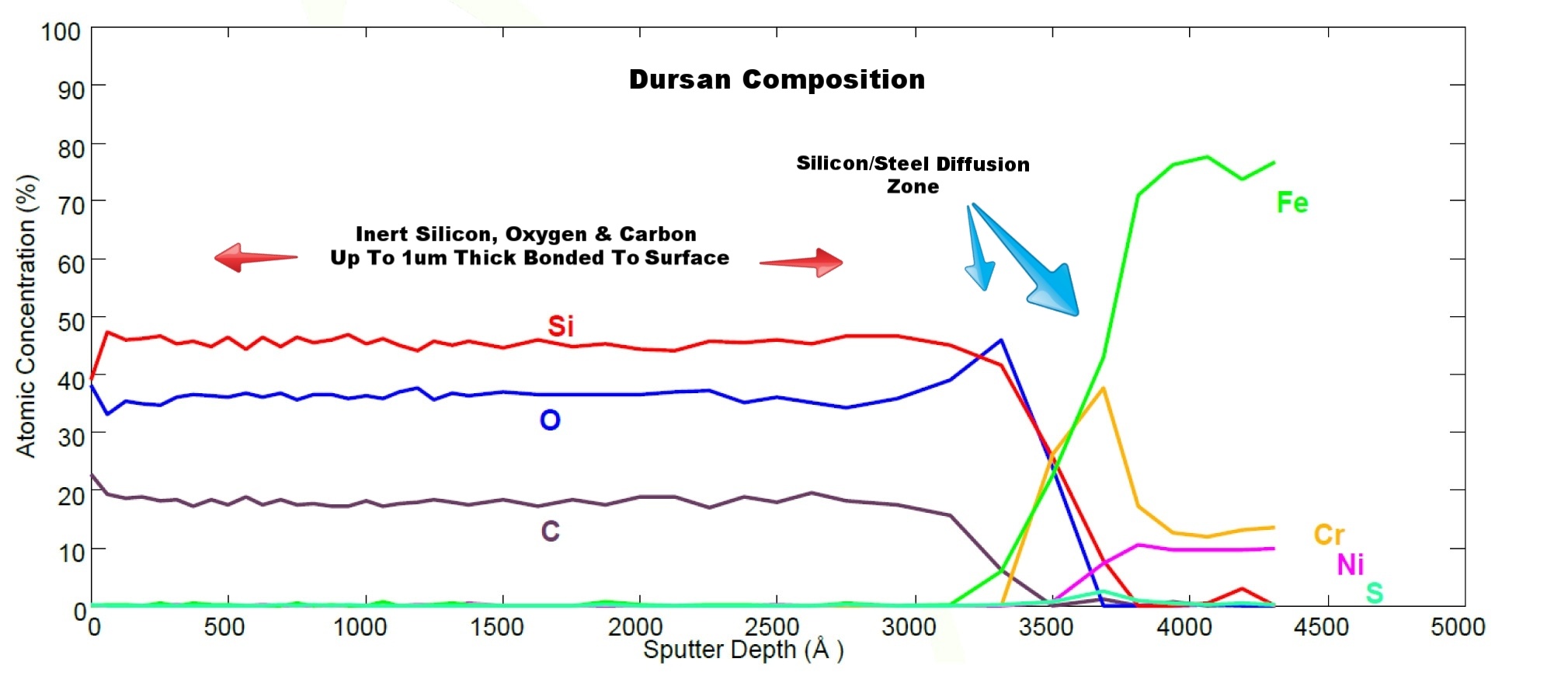

This destructive technique is widely used in material science to evaluate the composition of a surface . It's also handy for assessing the precise depth of a coating. The example below shows the composition and depth of a Dursan coating sample. Note how the silicon/steel diffusion zone is clearly delineated. Learn how SilcoTek creates the diffusion zone by reading about our coating technology.

The AES technique measures the material that comes off the surface as an electron beam is focused onto the surface. The electron beam bores into the surface and material characteristics are measured by a detector as the sputtered material is emitted.

AES equipment can be expensive and require specialized knowledge to operate. It also can be time consuming and is destructive to the surface so AES is not a realistic quick measurement tool for field or production surface evaluation.

Have more questions about how to evaluate a coating or about our coatings in general? Go to our Frequently Asked Questions Page.

Sectioning and optical techniques

Sectioning and optical techniques

A tried and true method for evaluating a thickness. Cutting a part in half and optically measuring the coating thickness can be an effective tool for micron level coating thickness measurement. It can however be difficult to measure the exact coating to base surface transition and is of course a destructive test. Again not a realistic quick measurement tool for the field. Accuracy is limited, especially when measuring sub-micron thick coatings.

F20 Thin-film Analyzer

F20 Thin-film Analyzer

SilcoTek’s F20 thin-film analyzer is a bench top tool that can be configured to measure thin film thicknesses (30Å to 350 mm), optical constants such as refractive index, extinction coefficient and transmittance. It is primarily used by SilcoTek as a quick, accurate and non-destructive way to measure surface thicknesses and to assure consistent coating quality. The analyzer relies on the refraction of light as it passes through a thin surface, reflects off the base surface, and then passes through the coating again. The instrument measures the change due to refraction and correlates that change to thickness standards. The base material, the surface roughness, and coating refractive index can play a big part in the effectiveness and reliability of this measurement technique.

X-ray Fluorescence Analyzers (XRF and ED-XRFA) and X-Ray Spectrometry

X-ray Fluorescence Analyzers (XRF and ED-XRFA) and X-Ray Spectrometry

Used primarily by plating shop for measuring the thickness of metallic plating, XRF can be a relatively low cost method to measure coating thickness. The surface is bombarded with x-ray, the coating and base material result in x-ray fluorescence radiation. The coating surface will attenuate the base material radiation, allowing the instrument to correlate thickness between the coating emission and base material emission. The method is non destructive and can be effective for sub micron measurement. XRF is effective in measuring most elements and alloy materials but not organic materials. The technique is commonly used in metal finishing operations.

Magnetic Induction and Pull-off Style Gauges

Magnetic Induction and Pull-off Style Gauges

Magnetic based pull-off or electromagnetic induction measurement tools rely on the differential of a magnetic base metal and a non conductive coating (like paint). The thicker the paint the less force needed to pull away the gauge. These can be an effective field test for rough evaluation of a coating thickness but not effective for extremely thin coatings or conductive coatings. Electromagnetic measurement tools can have an accuracy of +1%.

Ultrasonic measurement

Ultrasonic measurement

These hand held tools measure coating thickness on metallic base materials, ie. paint on a wood surface for example. There a quick non destructive way of measuring coating thickness, but not for a coating on a metal surface.

Gravimetric comparison

Gravimetric comparison

Basically measuring the weight of a coated and uncoated part. This method is a good way to measure bulk coatings but not effective for precision thin film measurement or for evaluating exact thickness at a particular location.

ASTM Methods Highlighting Coating Measurement

Reading ASTM methods can be very helpful in determining and using an approved thickness measurement method for your industry and application. Some methods that can help make thickness measurement easier are:

Have a question about coating thickness measurement when evaluating our coating in your process? Contact our technical service team or ask the experts.

Ask the experts.

Sectioning and optical techniques

Sectioning and optical techniques F20 Thin-film Analyzer

F20 Thin-film Analyzer X-ray Fluorescence Analyzers (XRF and ED-XRFA) and X-Ray Spectrometry

X-ray Fluorescence Analyzers (XRF and ED-XRFA) and X-Ray Spectrometry Magnetic Induction and Pull-off Style Gauges

Magnetic Induction and Pull-off Style Gauges Ultrasonic measurement

Ultrasonic measurement Gravimetric comparison

Gravimetric comparison